Distributed active fire extinguishing system for railway vehicle and control method

A fire extinguishing system and rail vehicle technology, applied in the field of distributed active fire extinguishing technology, can solve problems such as difficult to ensure rapid fire extinguishing or control of fire, secondary damage, time-consuming fire extinguishing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

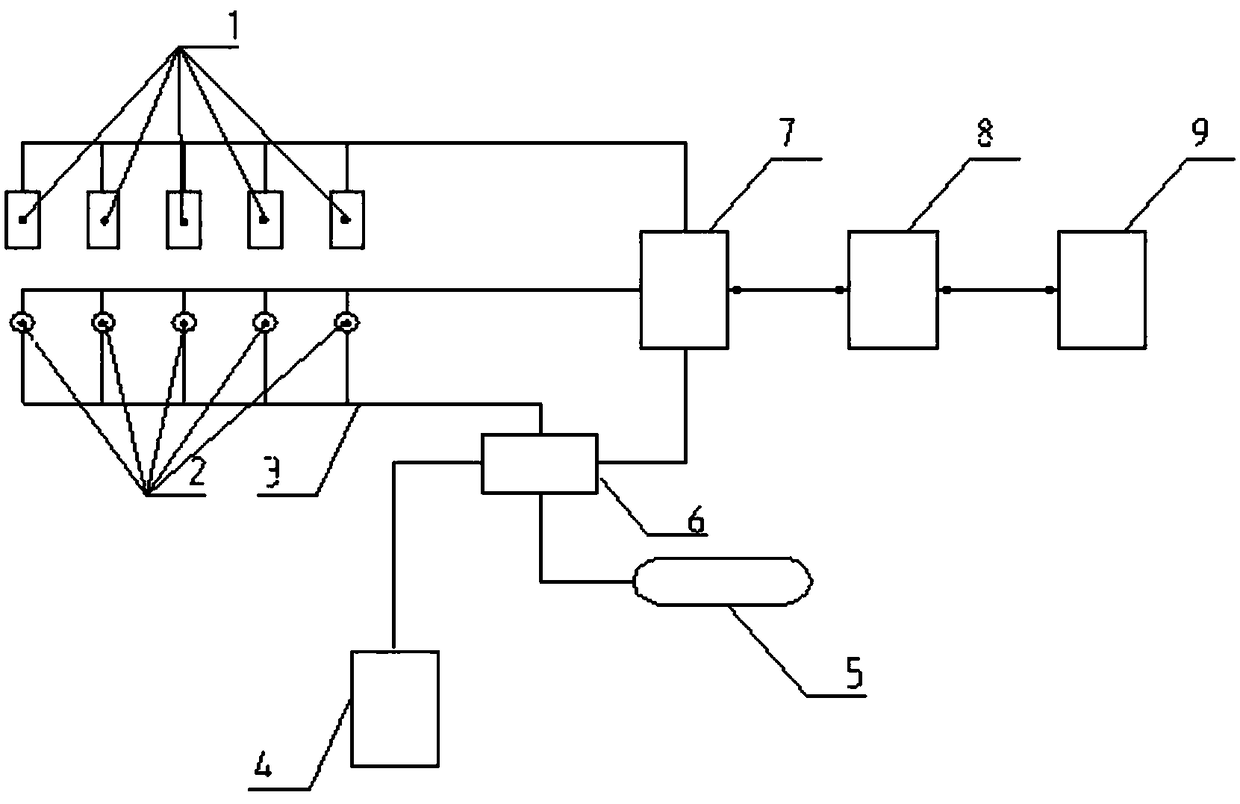

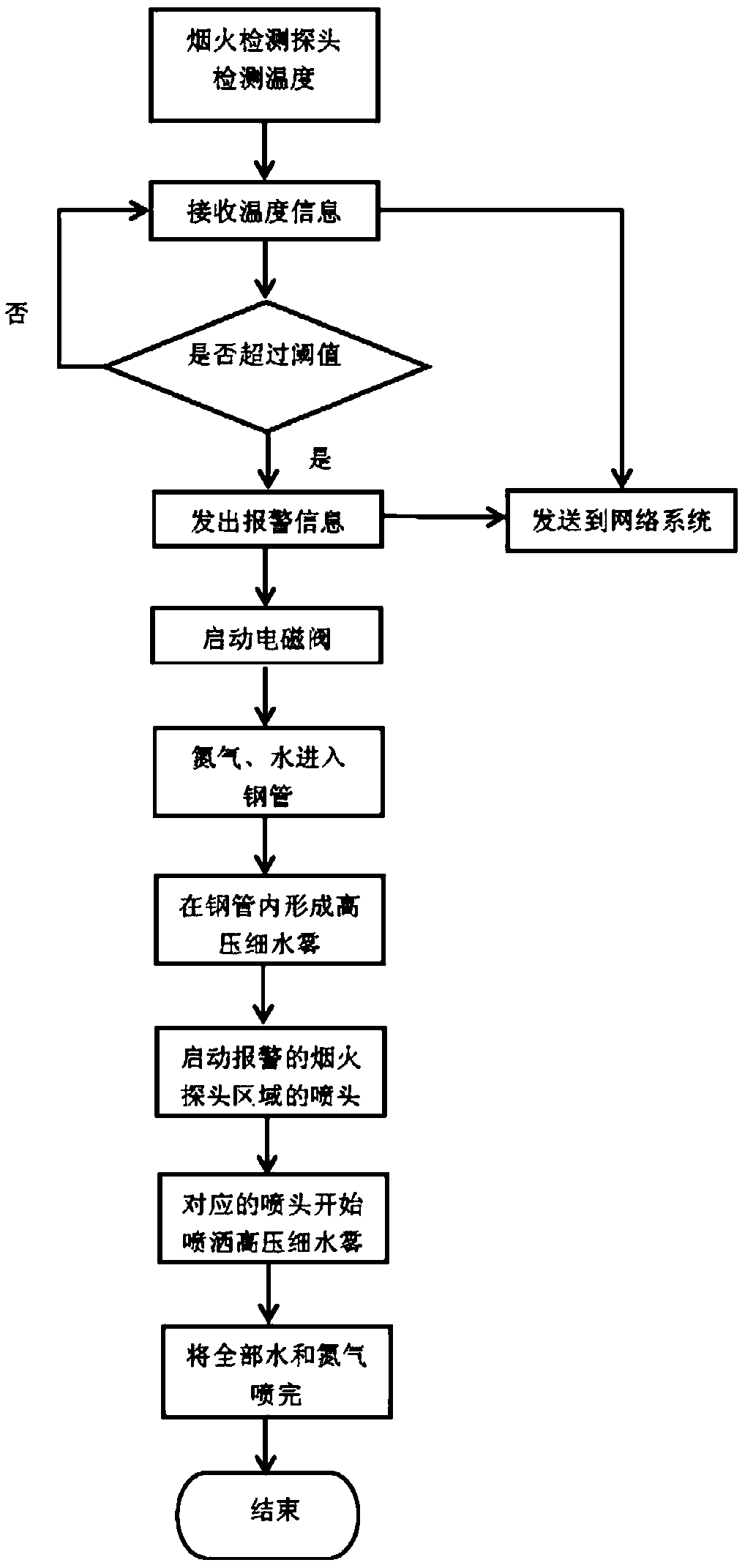

[0013] refer to figure 1 , install five radiant pyrotechnic detection probes 1 evenly on the center line of the roof of the passenger compartment of the vehicle, and install one fine water mist nozzle 2 on the center line of the roof at a distance of no more than 10 cm from each pyrotechnic probe, and These two components are defined as a group, and a total of 5 groups are installed in each vehicle; the radiation type smoke detection probe 1 is connected to the fire extinguishing system host 7 through a cable, and the fire extinguishing system host 7 is connected to the train network system 8, and the temperature field in the passenger compartment Real-time transmission to the train network system and display on the driver's display screen 9; the fine water mist nozzle 2 is connected to the water storage tank 4 and nitrogen cylinder 5 installed under the train through the steel pipe 3 and the solenoid valve 6, and the fire extinguishing system host 7 is connected to the solenoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com