Whole bridge integrally synchronized jacking support replacing system and construction method

A technology of simultaneous jacking and construction methods, applied in bridges, bridge maintenance, bridge reinforcement and other directions, can solve the problems of uneven settlement cracks, high consumption costs, and long construction periods in bridge deck structures, so as to avoid bridge stress. All damage, simple operation and safety, the effect of safe bridge jacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further elaborated and described below in conjunction with the accompanying drawings and specific embodiments.

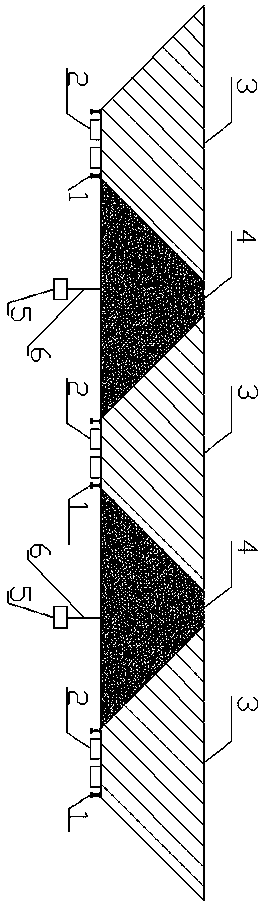

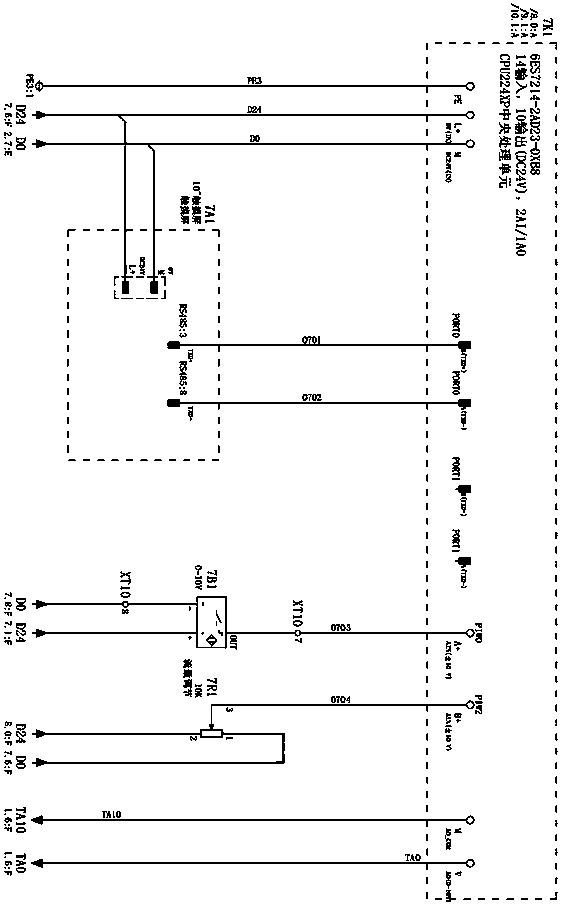

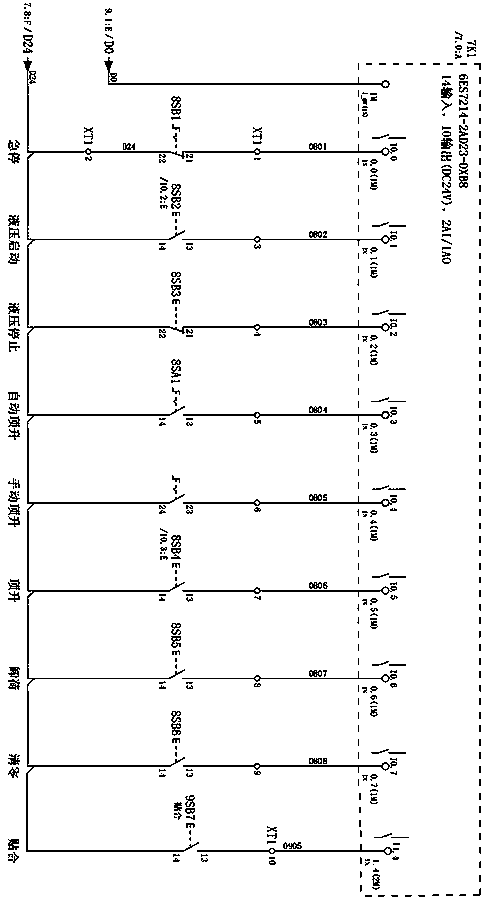

[0047] A bridge overall synchronous jacking support replacement system, such as Figure 1-20 As shown, the system is used to replace the sixteen supports 2 under the two prefabricated beams 3; the system includes a programmable logic controller (PLC) and two hydraulic pump stations, the hydraulic pump station mainly includes a motor and an oil pump. The single-chip microcomputer of the above motor is connected to the programmable controller, the motor is connected to the frequency converter, the oil pump is connected to the jacking cylinder through the oil pipe, and the jacking valve and unloading valve of the jacking cylinder are connected to the programmable controller. The pumping station is connected to eight jacking cylinders, which are connected to the oil pump through an oil diverter. Each jackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com