cu 2 S/imidazole compound/tempo catalyzes the method for preparing aldehyde by air oxidation of alcohol

A technology of compounds and imidazoles is applied in the field of catalytic air oxidation of alcohol to prepare aldehydes, which can solve the problems of difficult recovery of homogeneous catalysts, and achieve the effects of high yield, good substrate applicability and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

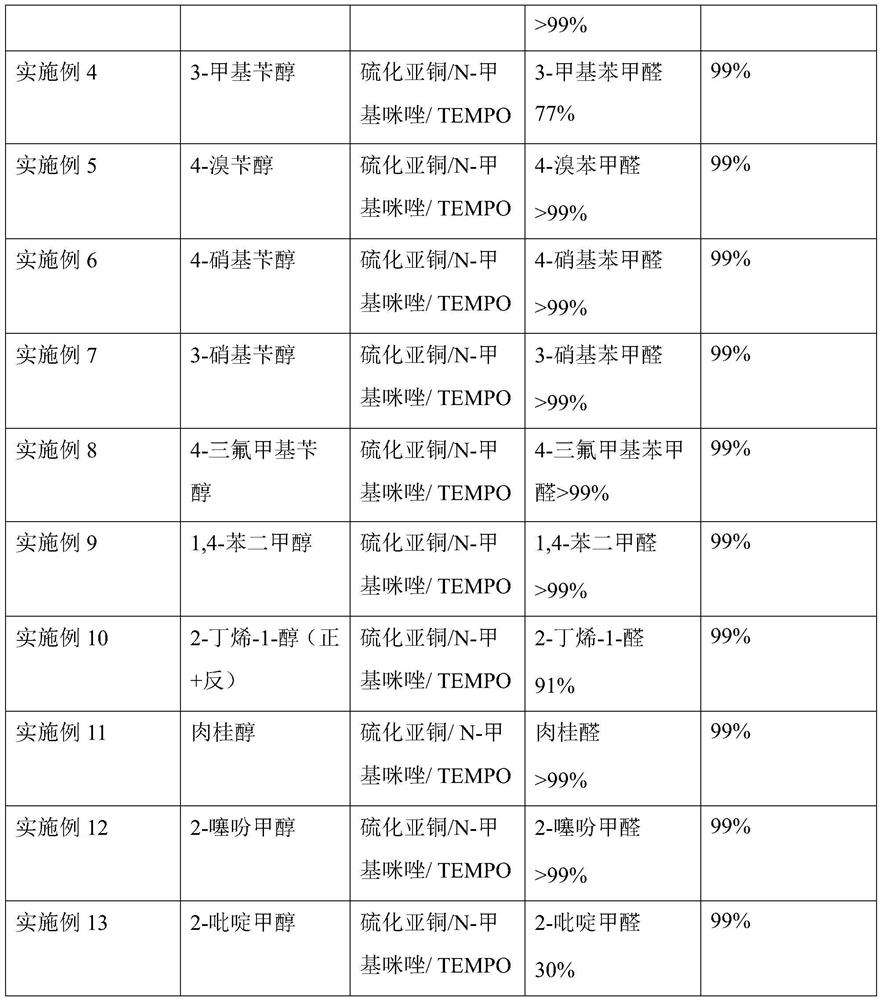

Examples

Embodiment 1

[0016] In a 25mL reaction flask, add cuprous sulfide (19.9mg, 0.125mmol), then add N-methylimidazole (20.5mg, 0.25mmol), TEMPO (19.5mg, 0.125mmol) and benzyl alcohol (540.6mg, 5mmol) ), 6 mL of acetonitrile. Stir vigorously in air at 25 °C for 24 h. After 24 hours of reaction cessation, pipette 0.5 mL of internal standard (o-dichlorobenzene) into a 10 mL volumetric flask and dilute to volume with acetonitrile, use an organic microporous filter membrane to filter, draw and inject 0.2 μL of the filtered solution, The product was analyzed by gas chromatography. According to the internal standard-standard curve method, the calculated yield of benzaldehyde was 98%, and the gas phase analysis purity was 99%. The chemical formula is as follows:

[0017] in,

[0018] N-methylimidazole, referred to as NMI;

Embodiment 2

[0020] In the 25mL reaction flask, add cuprous sulfide (19.9mg, 0.125mmol) respectively, then add N-methylimidazole (20.5mg, 0.25mmol), TEMPO (19.5mg, 0.125mmol) and 4-methylbenzyl alcohol ( 610.9mg, 5mmol), 6mL acetonitrile. Stir vigorously in air at 25 °C for 24 h. Use a pipette to pipette 0.2mL of the reaction solution, then use acetonitrile to make up to volume in a 5mL volumetric flask, filter with an organic microporous membrane, absorb 0.2μL of the filtered solution, and analyze it by gas chromatography-mass spectrometry product. The yield of 4-methylbenzaldehyde is >99%, and the purity by gas phase analysis is 99%.

Embodiment 3

[0022] In the 25mL reaction bottle, add cuprous sulfide (19.9mg, 0.125mmol) respectively, then add N-methylimidazole (20.5mg, 0.25mmol), TEMPO (19.5mg, 0.125mmol) and 2-methylbenzyl alcohol ( 610.9mg, 5mmol), 6mL acetonitrile. Stir vigorously in air at 25 °C for 24 h. Use a pipette to pipette 0.2mL of the reaction solution, then use acetonitrile to make up to volume in a 5mL volumetric flask, filter with an organic microporous membrane, absorb 0.2μL of the filtered solution, and analyze it by gas chromatography-mass spectrometry product. The yield of 2-methylbenzaldehyde is >99%, and the purity by gas phase analysis is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com