Catalytic synthesis method of anhydride

A synthesis method and technology for carboxylic acid compounds, applied in the direction of organic chemistry and the like, can solve the problems of expensive and complex catalyst synthesis, difficult to realize industrialization, and high economic cost, and achieve economical and cheap substrates and solvents, simple substrates and solvents, and catalytic systems. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

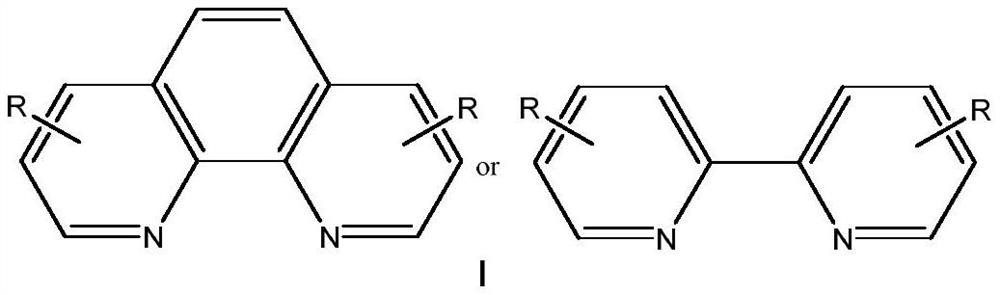

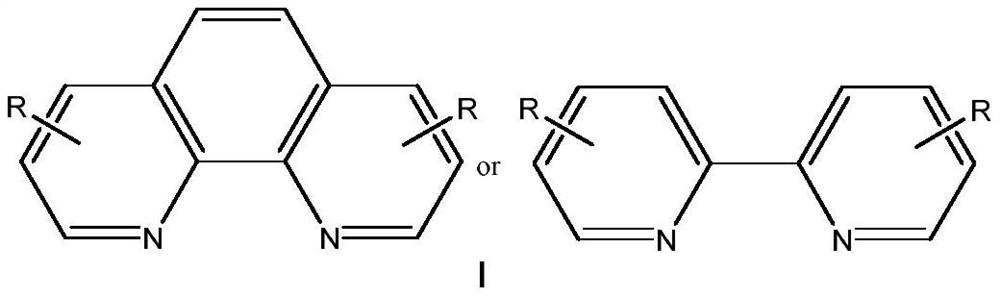

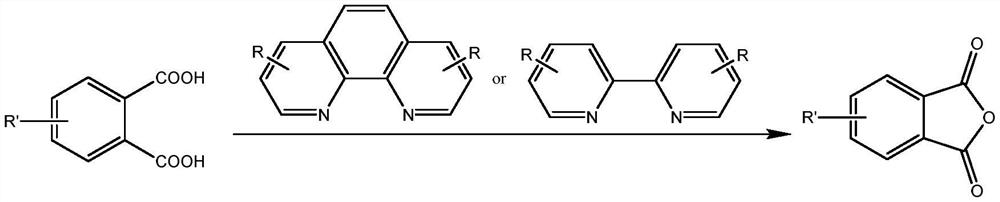

Method used

Image

Examples

Embodiment 1

[0031] Example 1: In a 25ml three-necked flask, add 4,7-diphenyl-1,10-phenanthroline (84mg, 10mol%), phthalic acid (415mg, 2.5mmol), and finally add the solvent toluene (9mL ) and N,N-dimethylacetamide (1ml), the mixture was heated under azeotropic reflux for 12 hours, and the reflux was passed through molecular sieves to remove water. After the reaction was completed, it was cooled and filtered, and the solvent was removed to obtain 366 mg of phthalic anhydride with a yield of 99%.

[0032] The obtained product 1 H NMR data were characterized as follows: 1 H NMR (500 MHz, DMSO) δ 8.12-8.07 (m, 2H), 8.03-7.99 (m, 2H).

Embodiment 2-3

[0033] Embodiment 2-3: reduce the amount of catalyst, other reaction conditions are consistent with embodiment 1.

Embodiment 4

[0034] Embodiment 4: shorten reaction time and catalyst amount, other reaction conditions are consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com