Cantilever type automatic-locating welder and using method thereof

A welding machine and cantilever type technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of low manual welding welding effect of the oil tank of the press, improve welding efficiency and welding effect, ensure welding quality, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

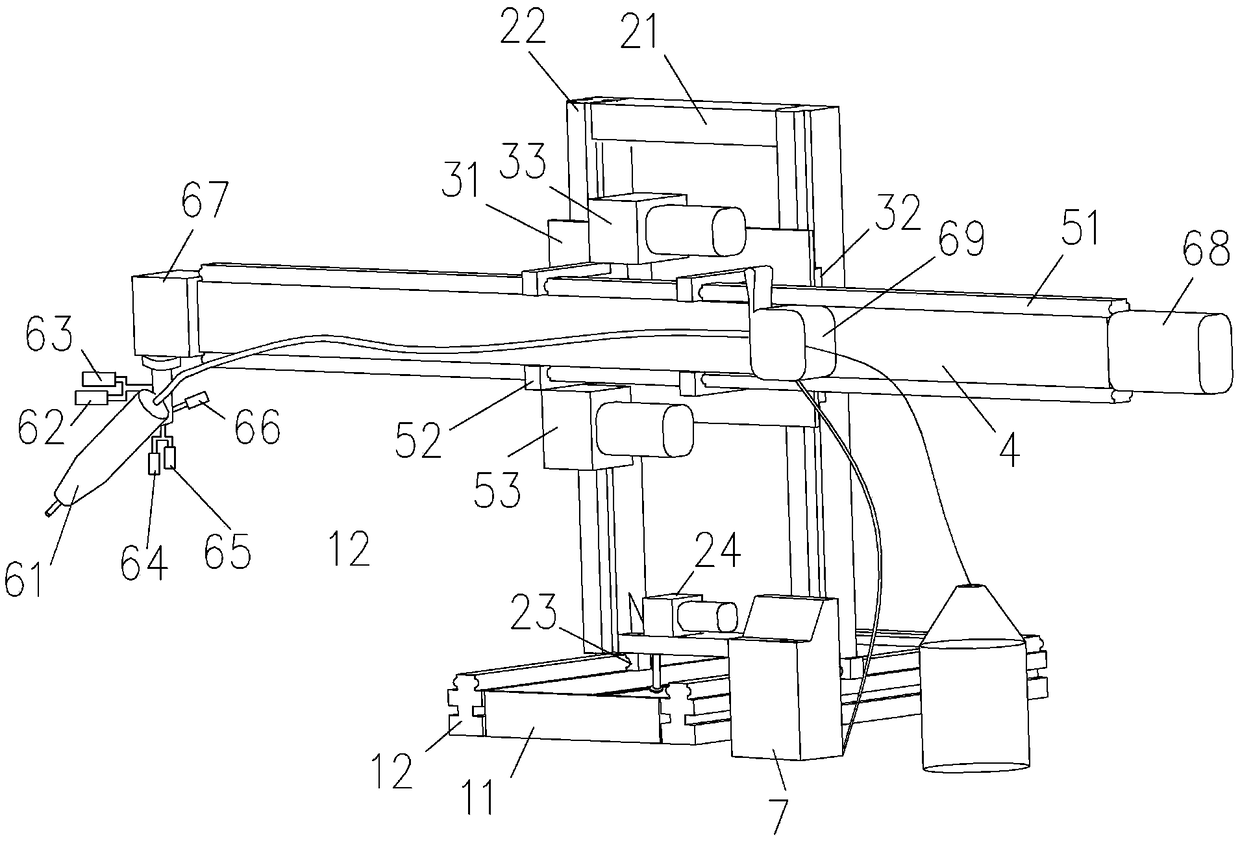

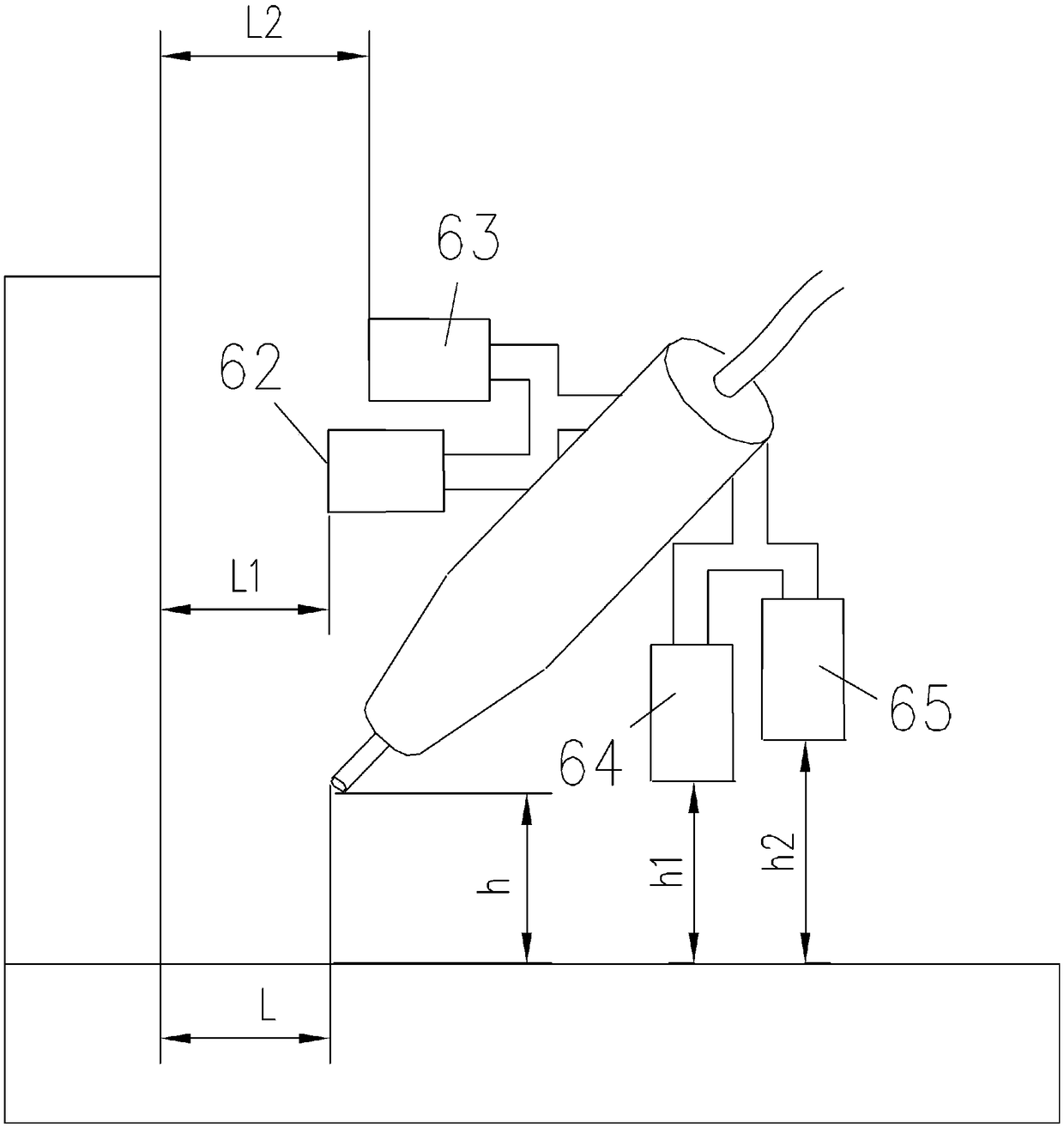

[0027] Such as Figure 1-5 As shown, the cantilever type automatic positioning welding machine of the present invention includes a horizontal guide rail seat, a vertical guide rail seat, a cantilever seat, a cantilever assembly, a welding torch head assembly and an electric console 7;

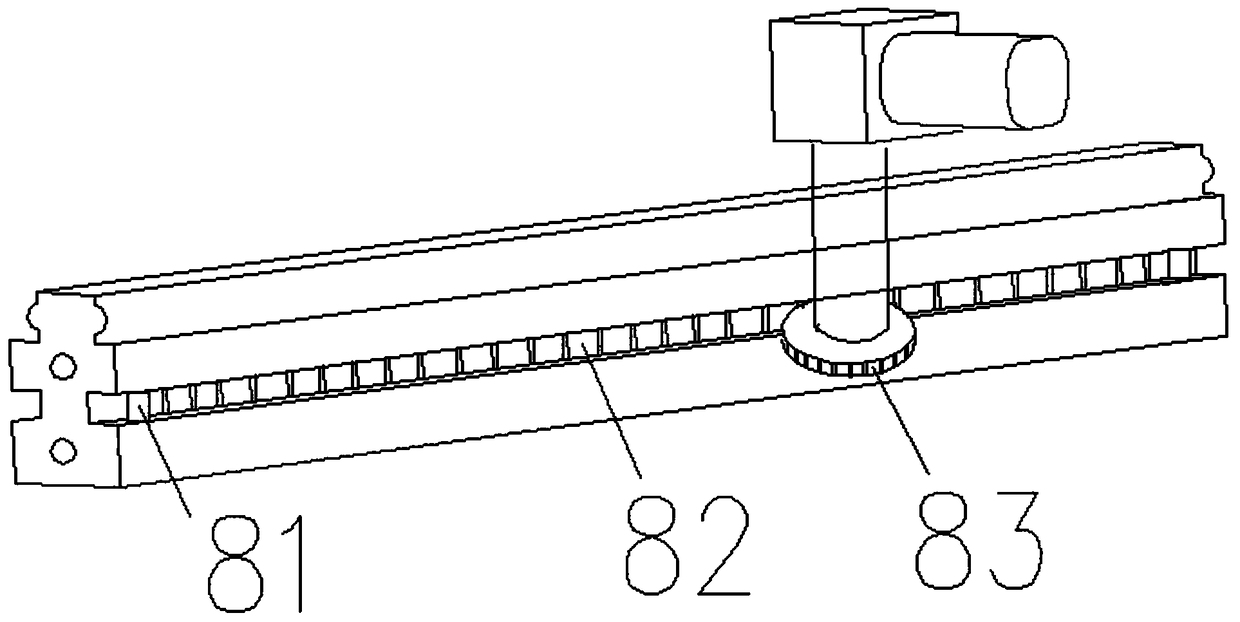

[0028] The horizontal guide rail seat includes a frame-type horizontal base 11 surrounded by four sides and two horizontal guide rails 12. The frame-type horizontal base 11 is laid horizontally on the ground, and the two horizontal guide rails 12 are arranged on both sides of the frame-type horizontal base 11 parallel to each other. , where the orientation of the horizontal guide rail 12 is recorded as the X-axis direction; as image 3 The schematic diagram of the horizontal guide rail and the vertical guide rail is as shown. The horizontal guide rail and the vertical guide rail adopt t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com