Multi-link vehicle tilt back mechanism

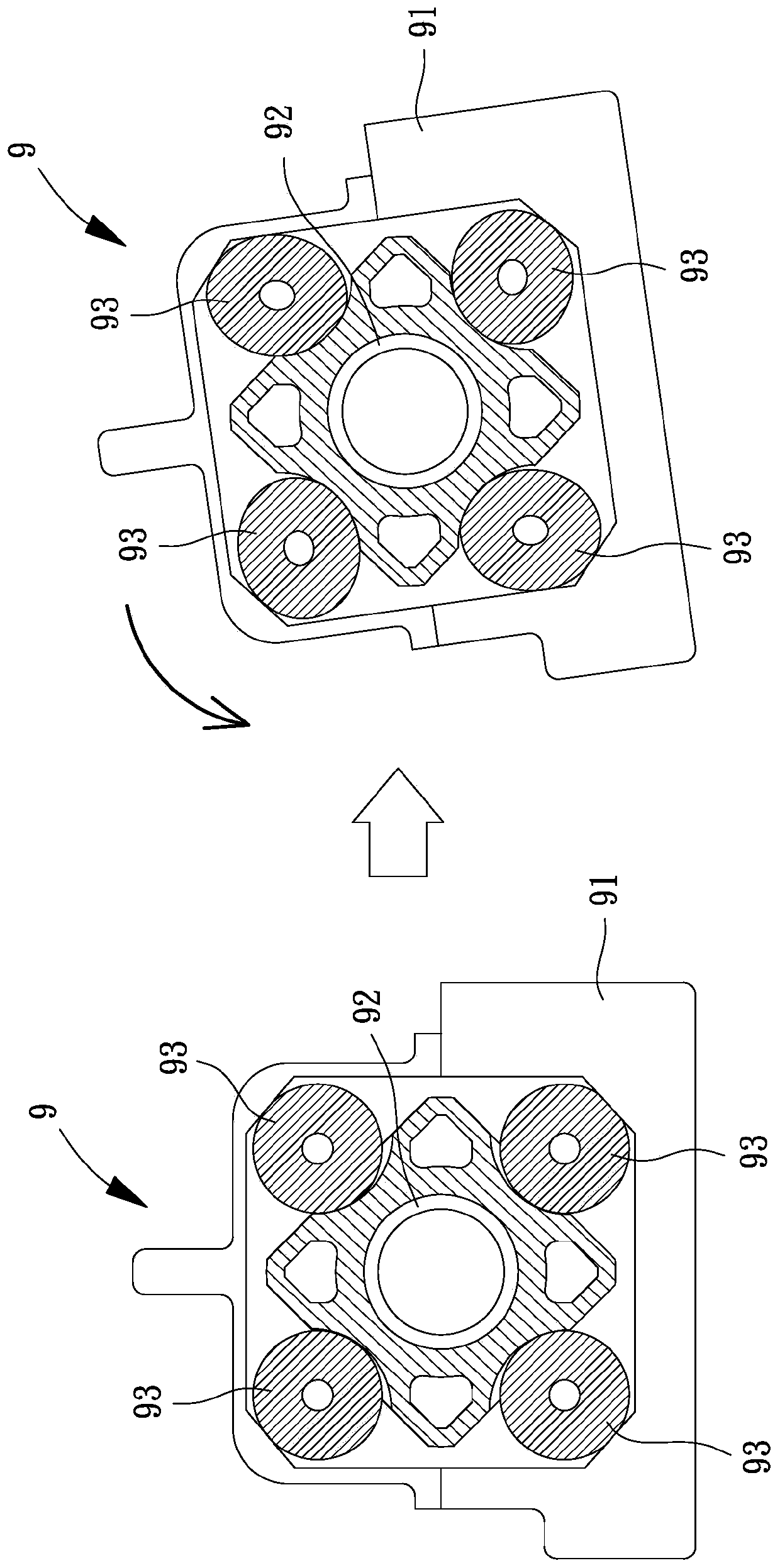

A multi-link, connecting rod technology, used in steering mechanisms, motor vehicles, bicycles, etc., can solve the problems of frequent maintenance, cracking, accelerated aging of the elastic body 93, etc., to avoid free rotation and deflection, improve the use of Convenience and the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are listed below, together with the accompanying drawings, and are described in detail as follows:

[0043] In the present invention, the directionality described below or its approximate terms are based on the direction when driving the vehicle. For example, the front frame direction is "front" and the rear frame direction is "rear"; other directions or their approximations and so on.

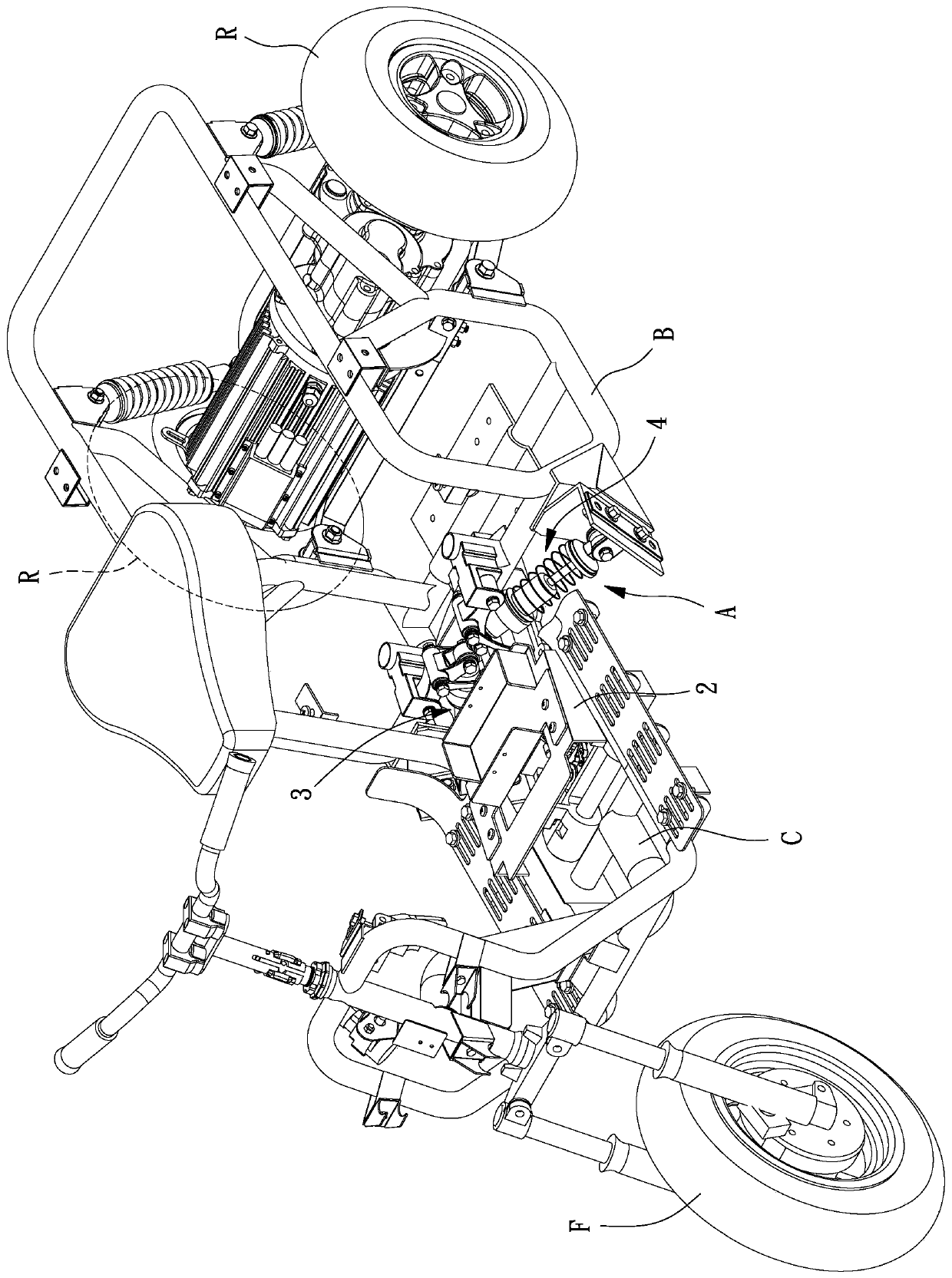

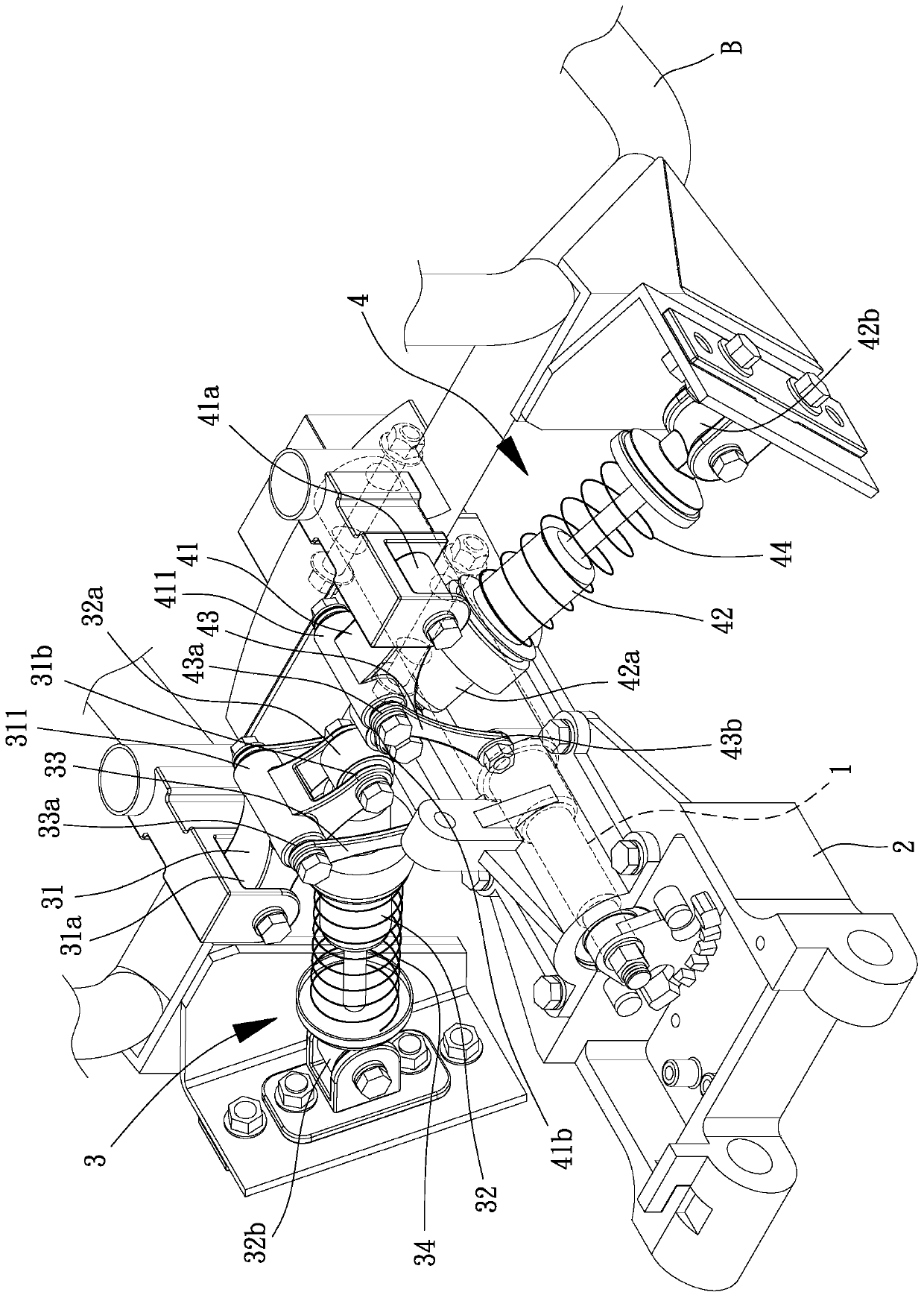

[0044] Please refer to figure 2 , image 3 , the multi-link vehicle leaning mechanism A of the present invention can be assembled between a rear frame B and a front frame C of a tricycle, the rear frame B is assembled with two rear wheels R, and the front frame C is assembled with a front wheel F; the multi-link vehicle reclining mechanism A generally includes a fixed shaft 1, a rotating member 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com