Storage box for rubber processing raw material

A technology for processing raw materials and storage boxes. It is used in containers to prevent decay, packaging objects under special gas conditions, biological packaging, etc. It can solve problems such as affecting the work efficiency of workers, sticking rubber raw materials together, and improper storage of rubber raw materials. , to achieve the effect of preventing extrusion deformation, improving work efficiency and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

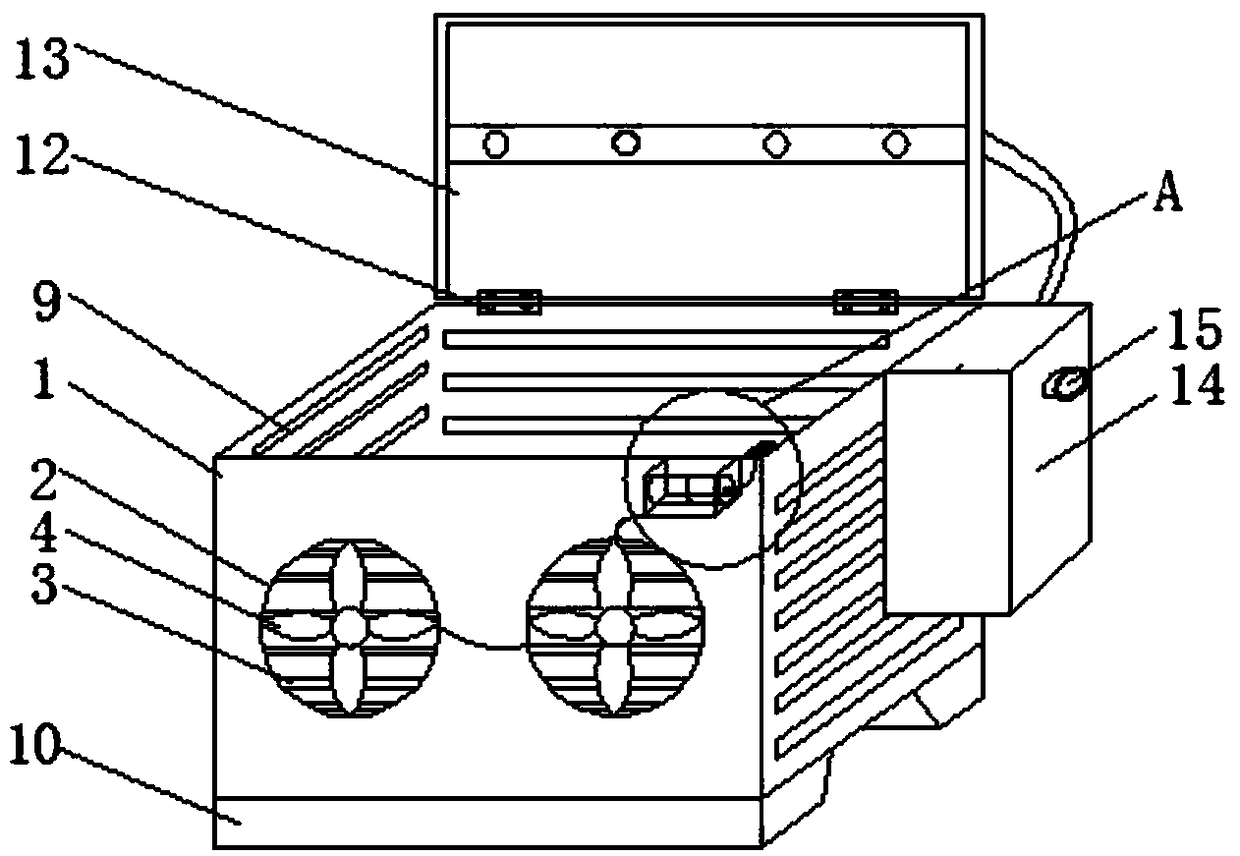

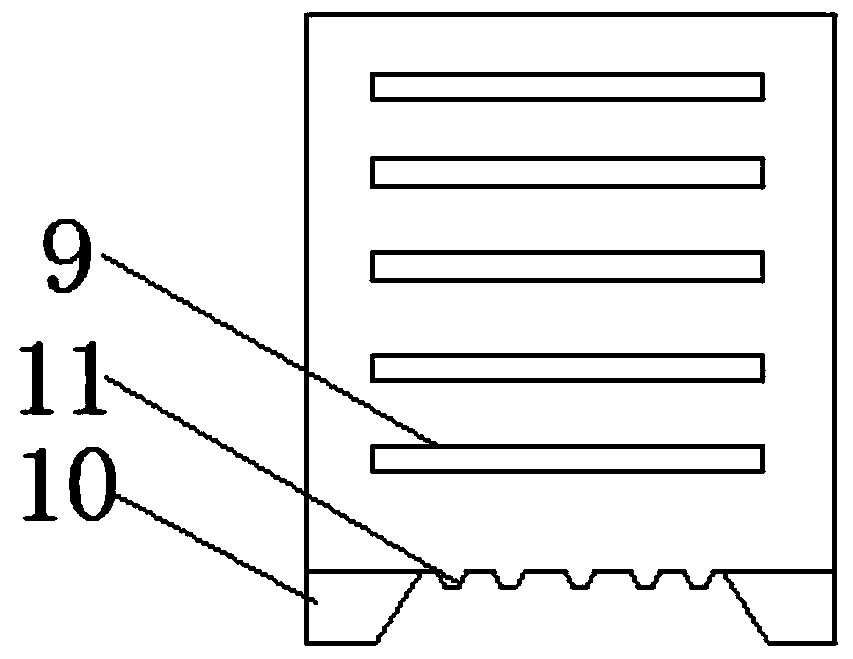

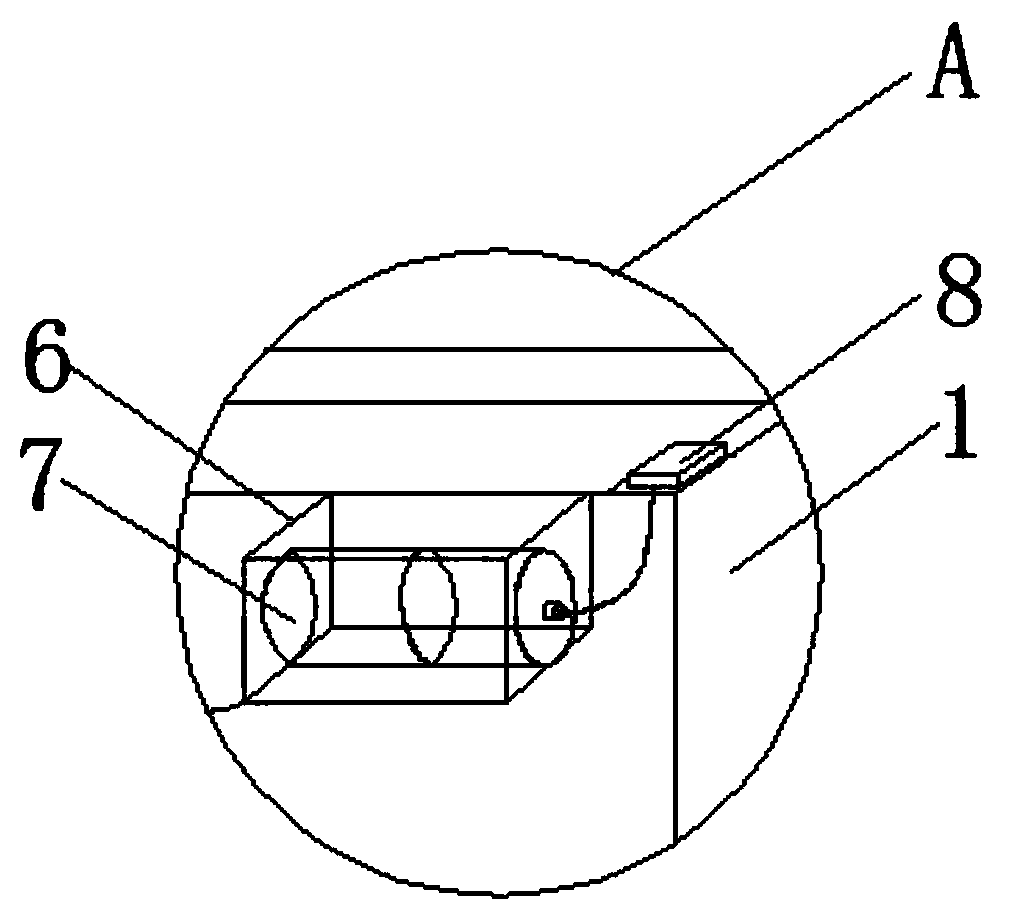

[0030] Such as Figure 1-3 As shown, a storage box for rubber processing raw materials includes a storage box body 1, a ventilation hole 2 is arranged on the front of the storage box body 1, a steel wire mesh 3 is arranged in the ventilation hole 2, and a Fan 4, a battery box 6 is installed on the front upper right of the storage box body 1, a battery 7 is housed in the battery box 6, a push switch 8 is arranged on the inside of the storage box body 1 near the corner of the battery box 6, the battery box 7, the fan 4 and the push switch 8 are connected in series through wires, and the left and right side walls and the rear side walls of the storage box body 1 are provided with air outlets 9, and the bottom, front and rear sides of the storage box body 1 are horizontally equipped with supporting feet 10, two supporting feet Air vent 11 is arranged between 10, and the upper end of storage box body 1 is connected with box body top cover 13 through hinge 12 rotation.

[0031] Aft...

Embodiment 2

[0033] Such as Figure 1-5 As shown, a storage box for rubber processing raw materials includes a storage box body 1, a ventilation hole 2 is arranged on the front of the storage box body 1, a steel wire mesh 3 is arranged in the ventilation hole 2, and a Fan 4, a battery box 6 is installed on the front upper right of the storage box body 1, a battery 7 is housed in the battery box 6, a push switch 8 is arranged on the inside of the storage box body 1 near the corner of the battery box 6, the battery box 7, the fan 4 and the push switch 8 are connected in series through wires, and the left and right side walls and the rear side walls of the storage box body 1 are provided with air outlets 9, and the bottom, front and rear sides of the storage box body 1 are horizontally equipped with supporting feet 10, two supporting feet Air vent 11 is arranged between 10, and the upper end of storage box body 1 is connected with box body top cover 13 through hinge 12 rotation.

[0034] The...

Embodiment 3

[0037] Such as figure 1 , 2, 3 and 6, a storage box for rubber processing raw materials, including a storage box body 1, the front of the storage box body 1 is provided with a ventilation hole 2, a steel wire mesh 3 is arranged in the ventilation hole 2, and the ventilation hole 2 A fan 4 is installed on the outside of the storage box body 1, a battery box 6 is installed on the front upper right of the storage box body 1, and a battery 7 is housed in the battery box 6, and a push switch 8 is arranged on the inside of the storage box body 1 near the corner of the battery box 6, and the battery The box 7, the fan 4 and the push switch 8 are connected in series through wires, and the left and right side walls and the rear side walls of the box body 1 are provided with air outlets 9, and the bottom, front and rear sides of the storage box body 1 are horizontally equipped with supporting feet 10, Ventilation holes 11 are arranged between the two supporting feet 10 , and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com