No-tillage precision seeder

A technology of seeding machine and seeding mechanism, which is applied to the parts of seeding machine, seeding, electromechanical devices, etc., can solve the problems of broken belts in seeding and fertilizing, affecting the quality of seeding farming, and inability of continuous seeding and fertilizing. , to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

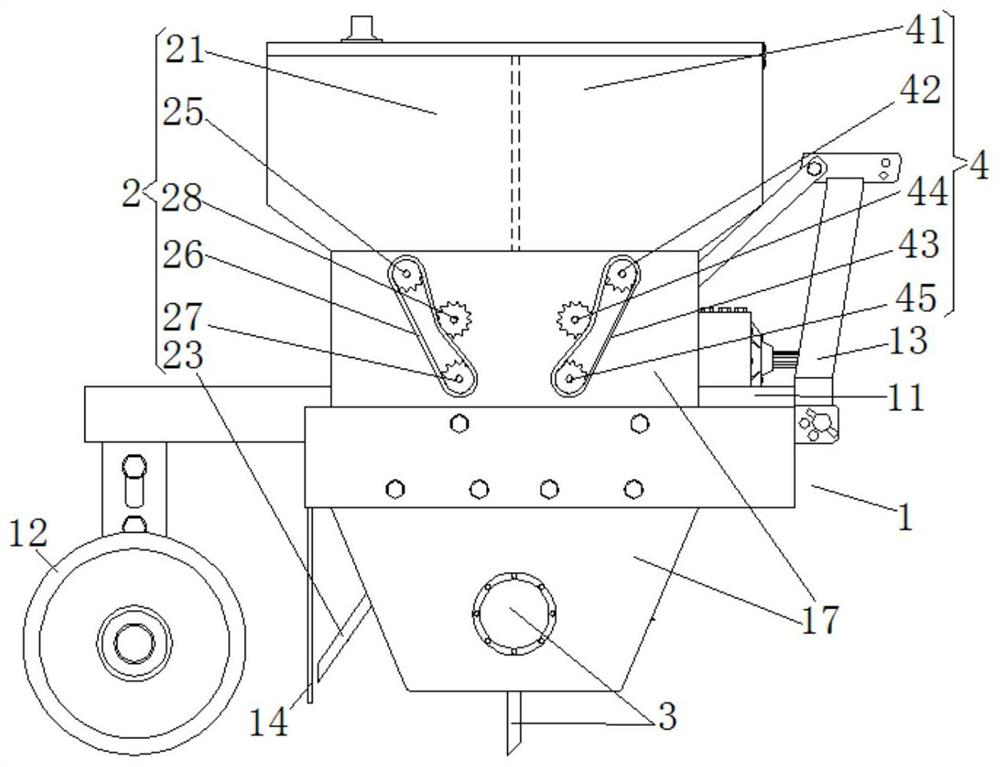

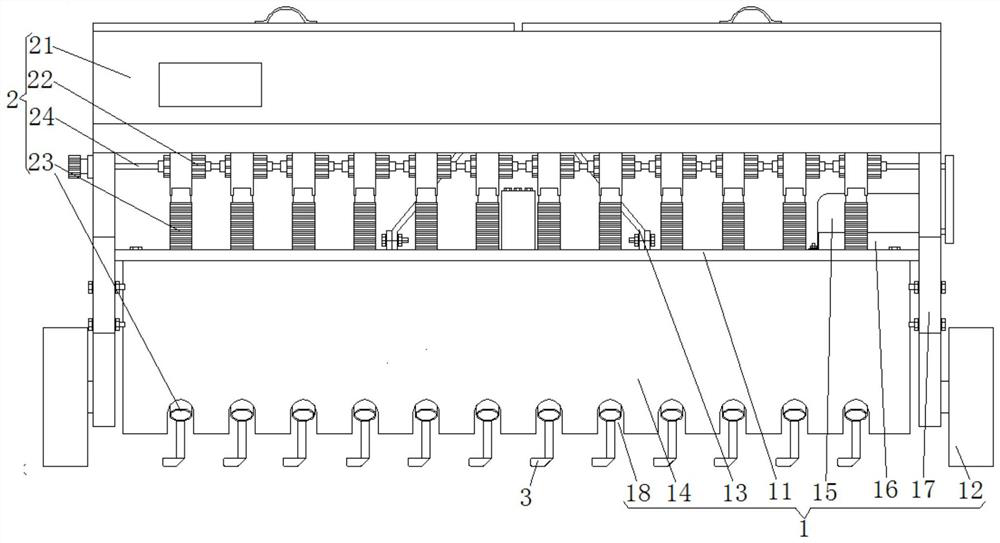

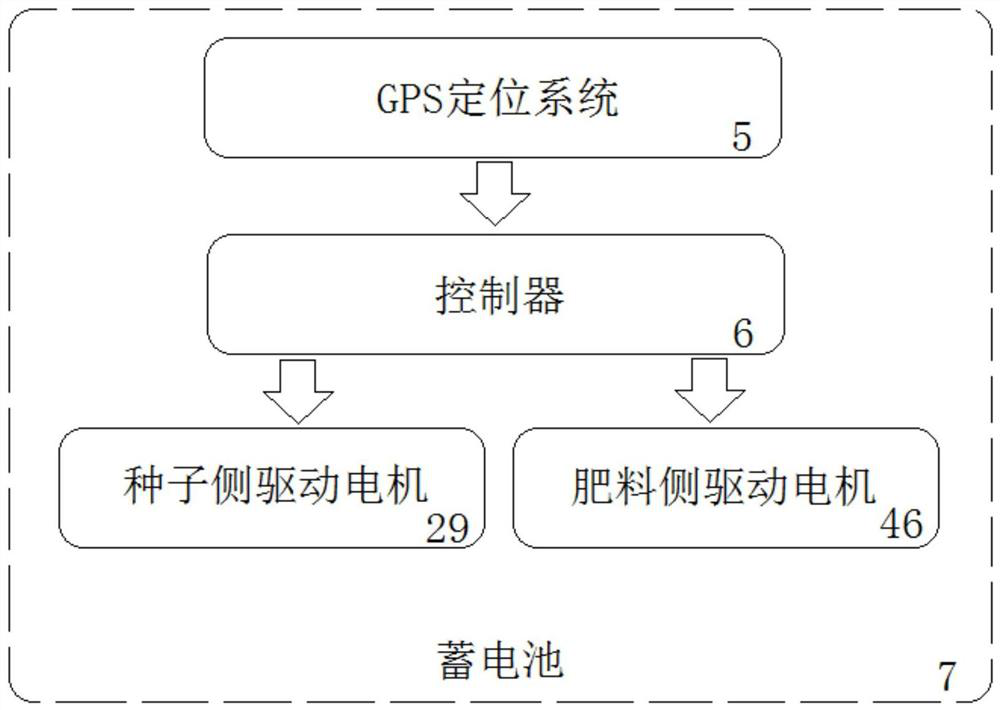

[0027] see figure 1 , figure 2 and image 3 As shown, the present invention includes a frame 1 , a seeding mechanism 2 , a rotary tillage mechanism 3 , a fertilization mechanism 4 , a GPS positioning system 5 and a controller 6 .

[0028]Among them, the frame 1 is mainly composed of side blocks 17 at both ends and a traction platform 11 connected between the side blocks 17 at both ends, and has a horizontal I-shaped structure. A trailer frame 13 extending forward is fixedly connected to the traction platform 11 of the frame 1. The frame 1 is connected to the rear side of an agricultural vehicle such as a tractor through the trailer frame 13, and the agricultural vehicle generates a driving force for walking. A rotatable support wheel 12 is respectively provided at both ends of the bottom rear side of the frame 1, and each support wheel 12 is connected with a corresponding shaft through a bearing assembly, and the shaft is connected at the bottom of the frame 1 through the b...

Embodiment 2

[0041] The invention includes a frame, a planting mechanism, a rotary tillage mechanism, a fertilization mechanism, a GPS positioning system and a controller.

[0042] Among them, the frame is mainly composed of side blocks at both ends and a traction platform connected between the side blocks at both ends, and has a horizontal I-shaped structure. A forwardly extending trailer frame is fixedly connected to the traction platform of the frame, and the frame is connected to the rear side of an agricultural vehicle, such as a tractor, through the trailer frame, and the agricultural vehicle generates a driving force for walking. A rotatable support wheel is respectively provided at both ends of the bottom rear side of the frame, each support wheel is connected with a corresponding shaft through a bearing assembly, and the shaft is connected to the corresponding end of the bottom rear side of the frame through the bearing assembly at the rear; the support wheels at both ends are at ...

Embodiment 3

[0054] The invention includes a frame, a planting mechanism, a rotary tillage mechanism, a fertilization mechanism, a GPS positioning system and a controller.

[0055] Among them, the frame is mainly composed of side blocks at both ends and a traction platform connected between the side blocks at both ends, and has a horizontal I-shaped structure. A forwardly extending trailer frame is fixedly connected to the traction platform of the frame, and the frame is connected to the rear side of an agricultural vehicle, such as a tractor, through the trailer frame, and the agricultural vehicle generates a driving force for walking. A rotatable support wheel is respectively provided at both ends of the bottom rear side of the frame, each support wheel is connected with a corresponding shaft through a bearing assembly, and the shaft is connected to the corresponding end of the bottom rear side of the frame through the bearing assembly at the rear; the support wheels at both ends are at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com