Dust collection device for bulk cement car loader

A technology of dust collection device and bulk cement, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of affecting work efficiency, personal harm, environmental damage, etc., and achieves the advantages of reasonable and simple structure, low production cost and improved applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

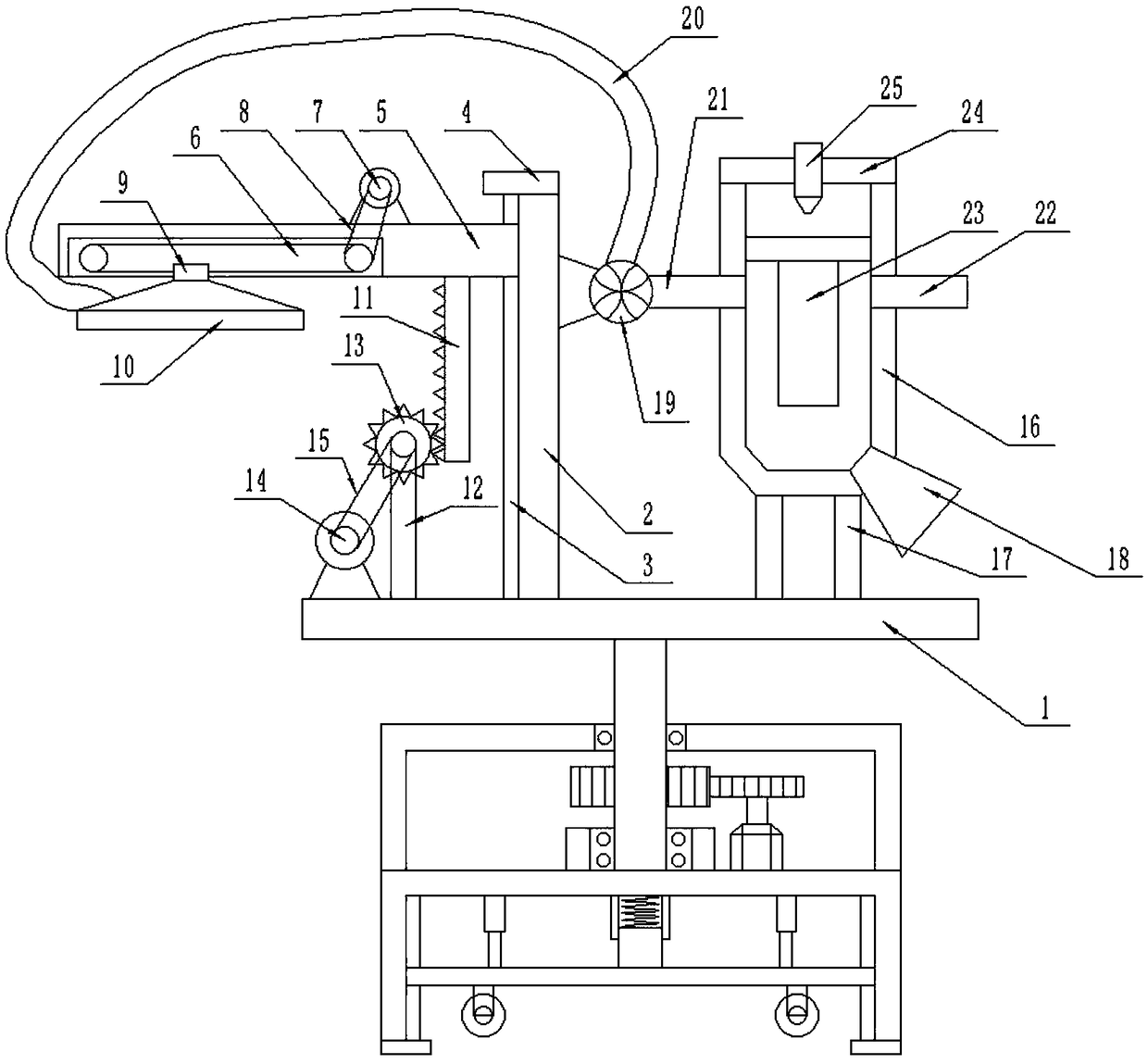

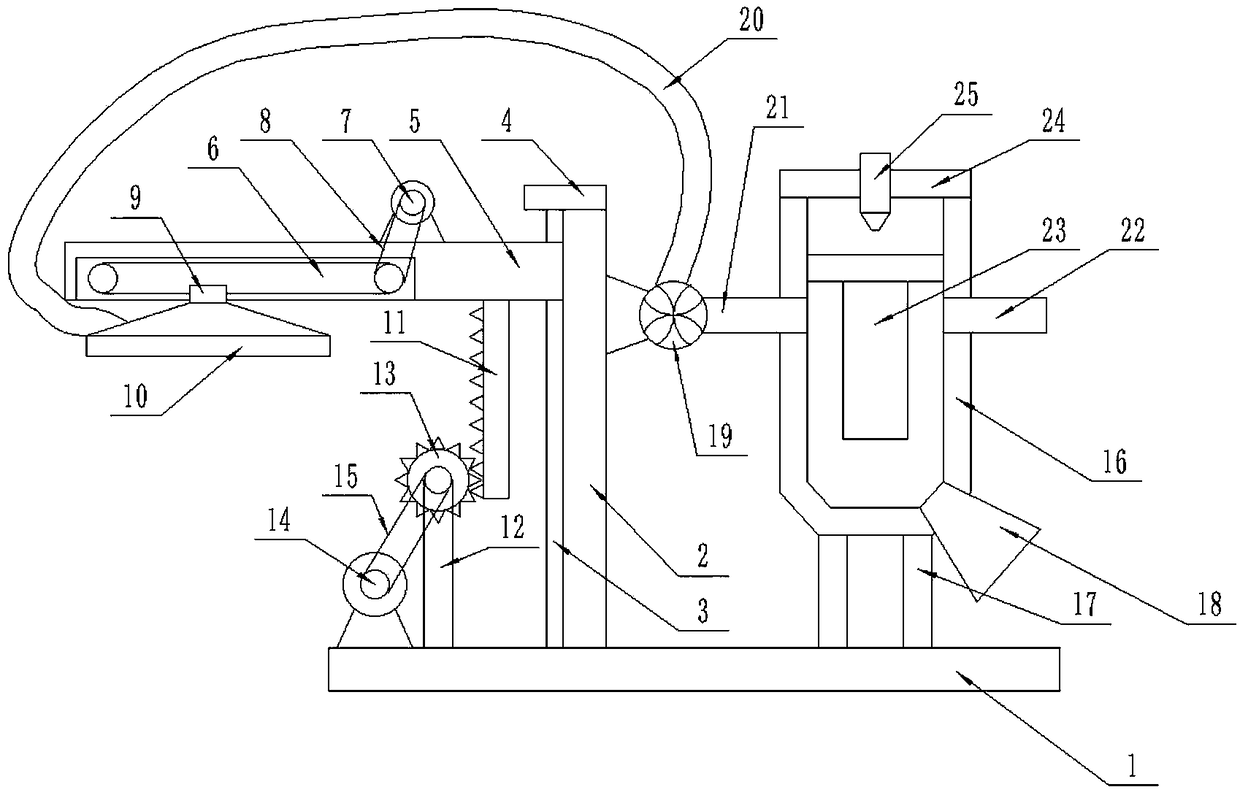

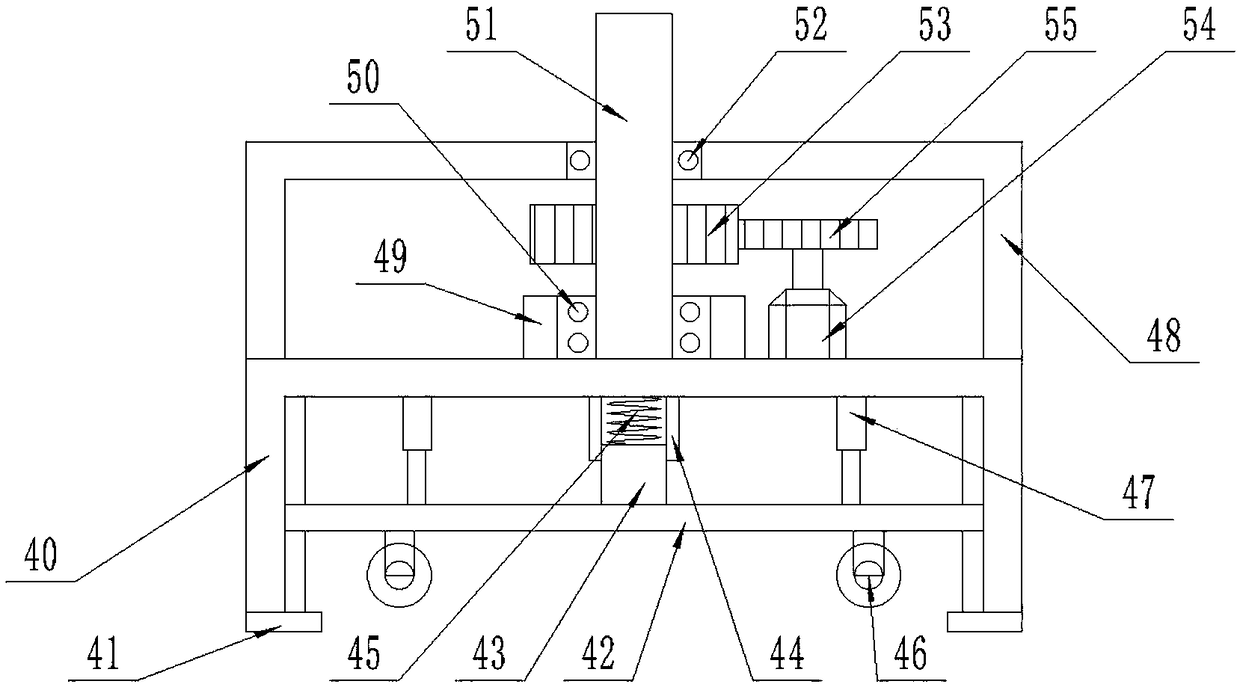

[0024] Such as Figure 1 to Figure 4 As shown, this specific embodiment adopts the following technical solutions: a dust collection device for a bulk cement loading machine, including a base 1, a vertical plate 2, a slide rail 3, a first limit block 4, a beam 5, a conveyor belt 6, a One motor 7, the first belt 8, the dust collection cover installation block 9, the dust collection cover 10, the rack 11, the gear installation rod 12, the gear 13, the second motor 14, the second belt 15, the filter chamber 16, the filter chamber support Rod 17, dust outlet 18, exhaust fan 19, hose 20, air inlet pipe 21, air outlet pipe 22, dust bag 23, top cover 24 and air blowing pipe 25; the left side of the upper surface of the base 1 is respectively fixedly connected with Vertical plate 2, gear mounting rod 12 and second motor 14; a slide rail 3 is fixedly connected to the left side of the vertical plate 2, and a first stop block 4 is fixedly connected to the top of the vertical plate 2, A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com