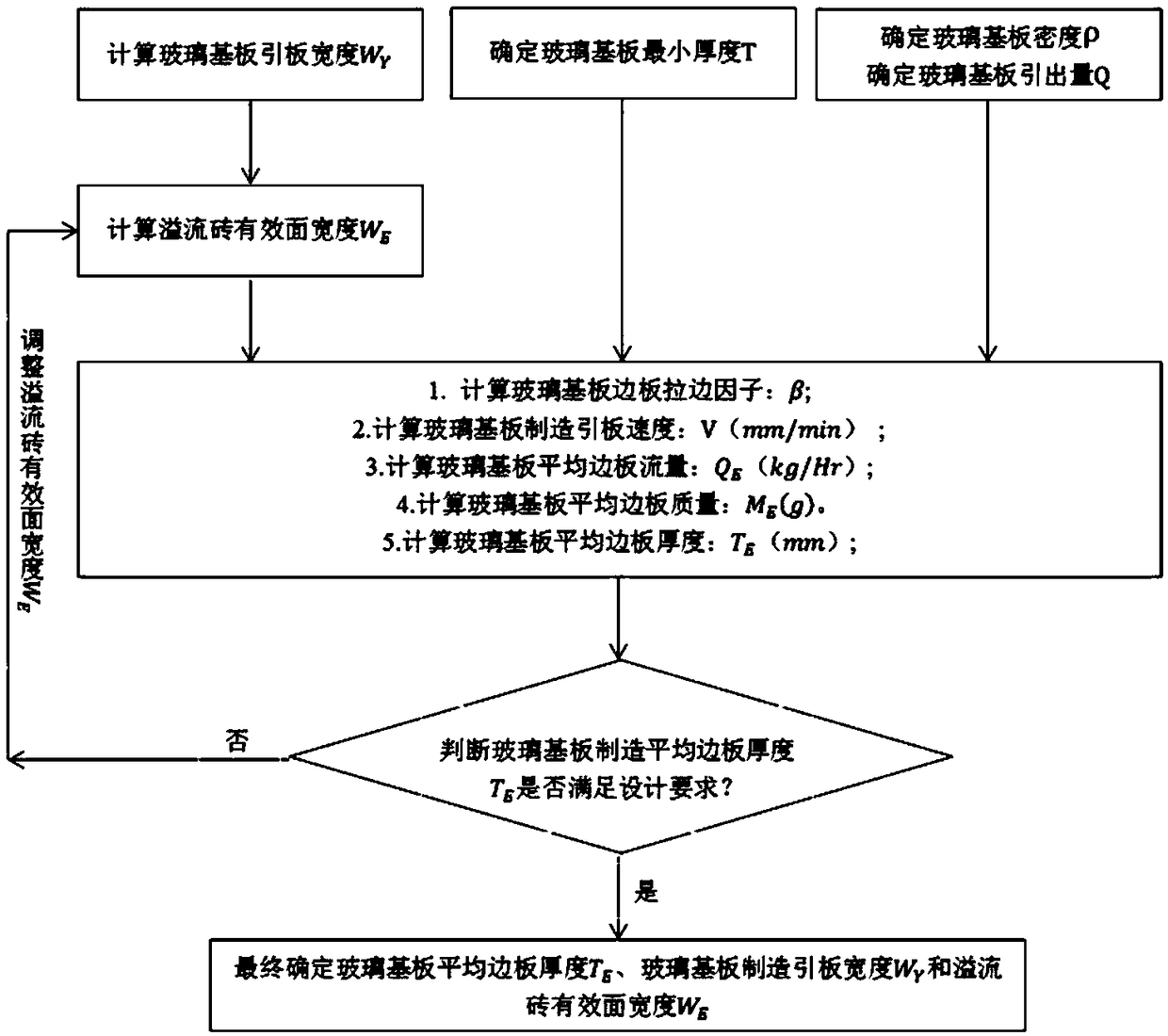

Design method of width of effective surface of overflow brick for controlling average thickness of edge plate

A technology of average thickness and design method, applied in glass manufacturing equipment, manufacturing tools, glass forming, etc., can solve problems such as plate fluctuations, achieve the effects of guarantee and consistency, optimize the forming thickness distribution, and solve the forming lead plate fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in further detail below in conjunction with accompanying drawing:

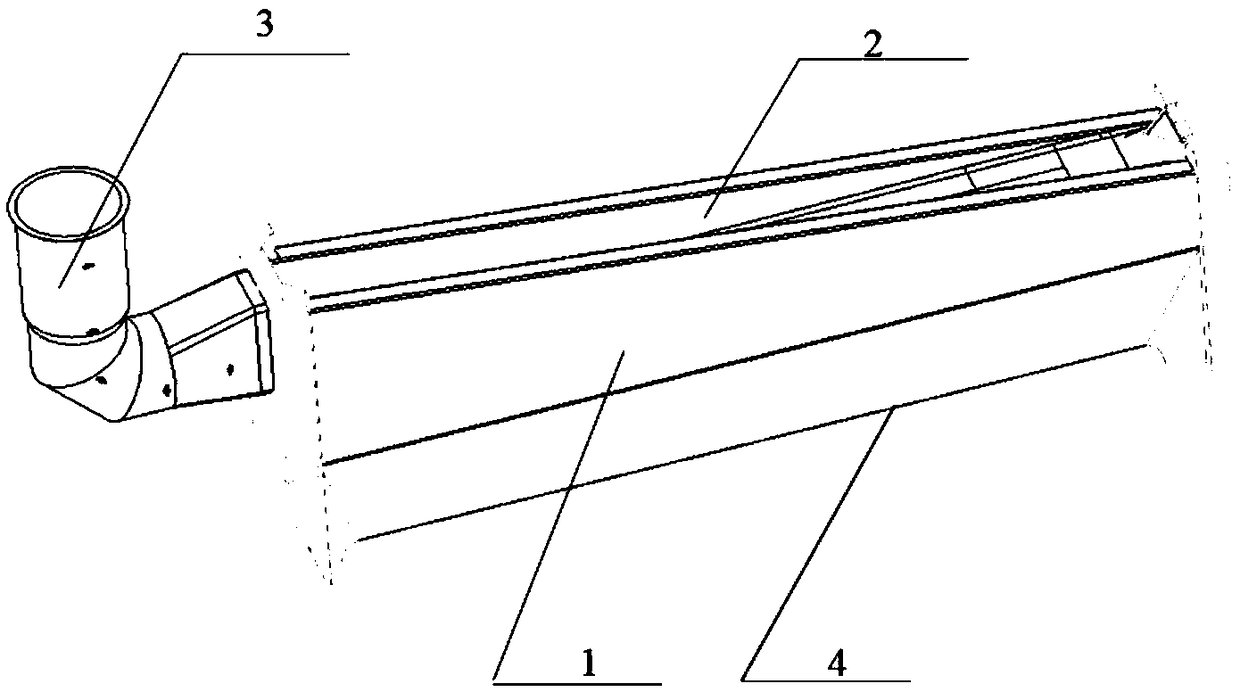

[0047] see figure 1 , The overflow system is composed of an overflow brick 1 and a glass liquid supply device 3 connected. There is an overflow groove 2 inside the overflow brick 1, and the bottom of the overflow brick 1 is the root of the overflow brick 1; when the glass substrate is manufactured by melting and overflowing, the glass melted by the glass melting furnace is melted in the forming process The liquid glass is supplied to the glass liquid supply device 3 in the melting overflow forming device, and overflows through both sides of the overflow brick 1 along the overflow groove 2, and forms a glass substrate from below the root 4 of the overflow brick 1.

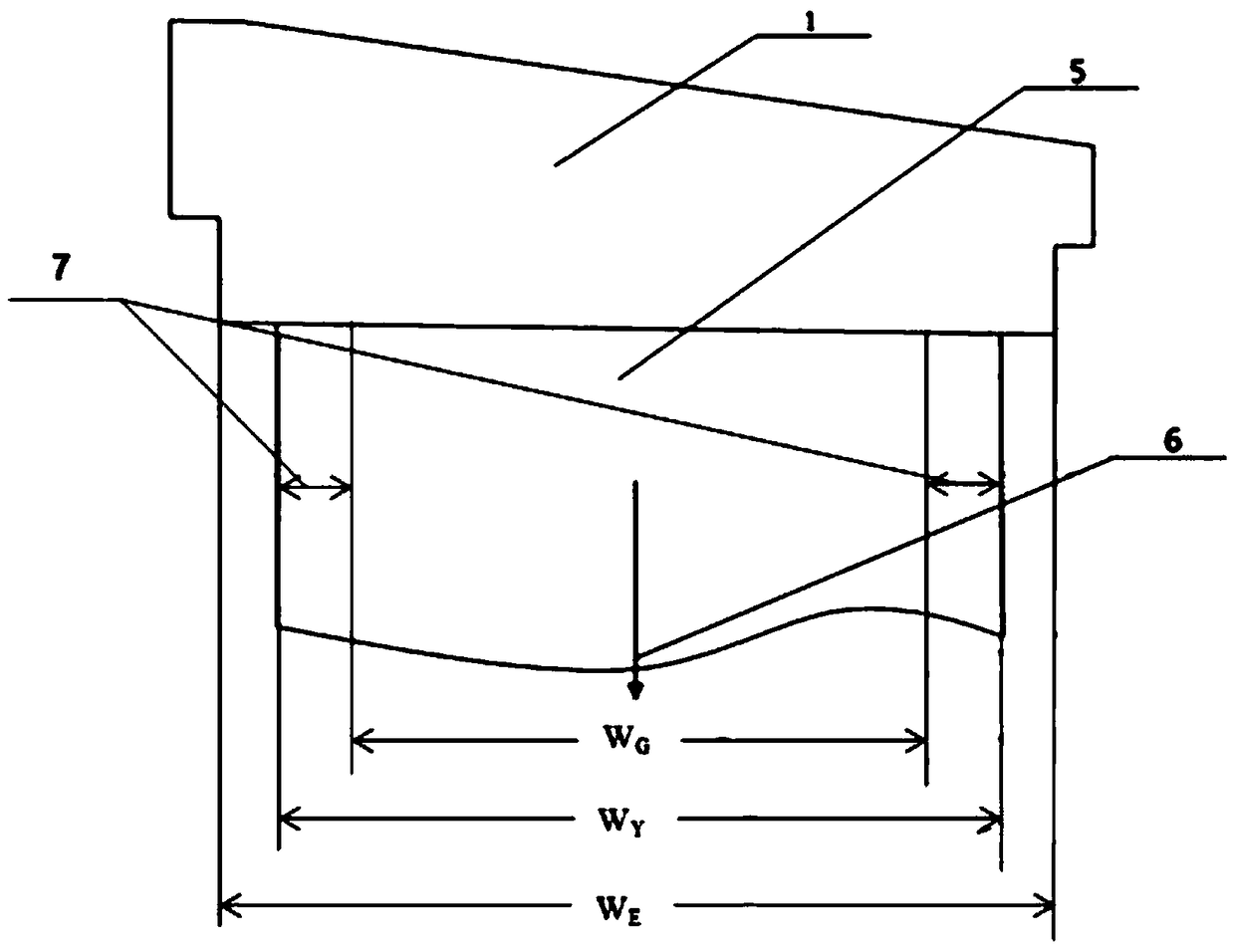

[0048] Such as figure 2 As shown, the lead plate is used as the forming basis of the glass substrate. During the process of down-molding the glass substrate, the formed glass substrate 5 moves downward al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com