High polymer modified asphalt waterproof membrane for railway concrete bridge deck and preparation method

A technology of asphalt waterproofing membrane and polymer modification, applied in asphalt coatings, bridges, bridge parts, etc., can solve the problems of affecting the quality of the membrane, reducing production efficiency, good sealing, etc., and improving high-temperature rheological properties , the effect of reducing temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

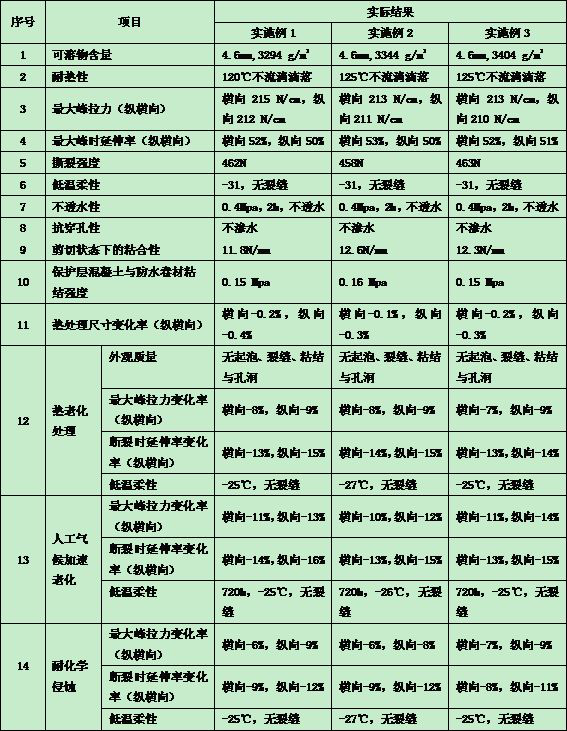

Embodiment 1

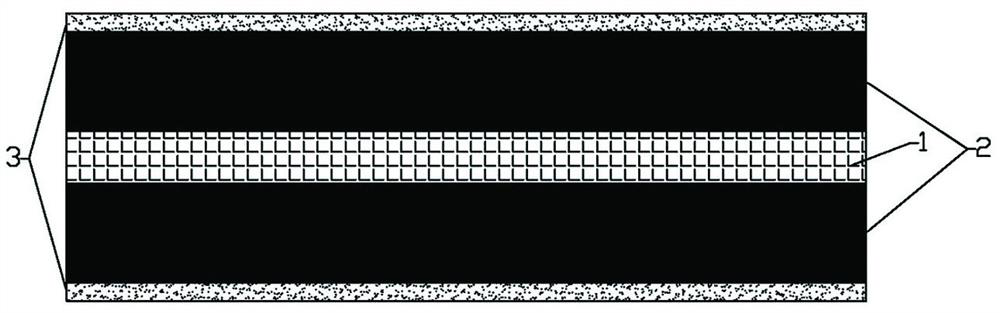

[0040] Embodiment 1: as figure 1 Shown, a kind of high polymer modified asphalt waterproof membrane material for railway concrete bridge deck, including base layer, the top and bottom of base base layer are coated with coating layer, and the outermost part of coating layer is coated with isolation layer, that is, on the base layer The upper and lower layers of the base layer are all coated with a coating layer. After bonding, an isolation layer is coated on the outermost of the upper coating layer and the lower coating layer. The base layer is a filament polyester tire, and the isolation layer is fine sand.

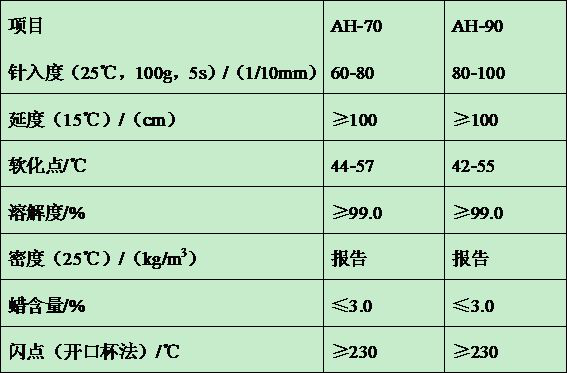

[0041] The coating layer is composed of the following raw materials: No. 10 asphalt 15 Kg, AH-70 asphalt 28 Kg, softening oil 12 Kg, SBS-1401 5 Kg, maleic anhydride grafted polypropylene wax 1 Kg, rubber powder 9 Kg, talcum powder 16 Kg.

[0042] The softening oil is a base lubricating oil with a pour point less than -20°C and a flash point greater than 230°C.

[0043] ...

Embodiment 2

[0055] Embodiment 2: as figure 1 Shown, a kind of high polymer modified asphalt waterproof membrane material for railway concrete bridge deck, including base layer, the top and bottom of base base layer are coated with coating layer, and the outermost part of coating layer is coated with isolation layer, that is, on the base layer The upper and lower layers of the base layer are all coated with a coating layer. After bonding, an isolation layer is coated on the outermost of the upper coating layer and the lower coating layer. The base layer is a filament polyester tire, and the isolation layer is fine sand.

[0056] The coating layer is composed of the following raw materials: No. 10 asphalt 25 Kg, AH-90 asphalt 48 Kg, softening oil 16 Kg, SBS-4403 9 Kg, maleic anhydride grafted polypropylene wax 4 Kg, rubber powder 4 Kg, talcum powder 25 Kg.

[0057] The softening oil is an aromatic oil with a pour point less than -20°C and a flash point greater than 230°C.

[0058] Rubber ...

Embodiment 3

[0070] Embodiment 3: as figure 1 Shown, a kind of high polymer modified asphalt waterproof membrane material for railway concrete bridge deck, including base layer, the top and bottom of base base layer are coated with coating layer, and the outermost part of coating layer is coated with isolation layer, that is, on the base layer The upper and lower layers of the base layer are all coated with a coating layer. After bonding, an isolation layer is coated on the outermost of the upper coating layer and the lower coating layer. The base layer is a filament polyester tire, and the isolation layer is fine sand.

[0071] The coating layer is composed of the following raw materials: No. 10 asphalt 20 Kg, AH-70 asphalt 35 Kg, softening oil 14 Kg, SBS-LG411 7 Kg, maleic anhydride grafted polypropylene wax 2.5 Kg, rubber powder 12 Kg, talcum powder 20 Kg.

[0072] The softening oil is base lubricating oil or aromatic oil with a pour point less than -20°C and a flash point greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com