Cured flue-cured tobacco flavor essence used in heat-not-burn cigarettes, preparation method and application thereof

A heat-not-burn and cigarette technology, which is applied in the field of cigarette flavors and fragrances, can solve problems such as not being designed, and achieve the effects of good satisfaction, promoting cell regeneration, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

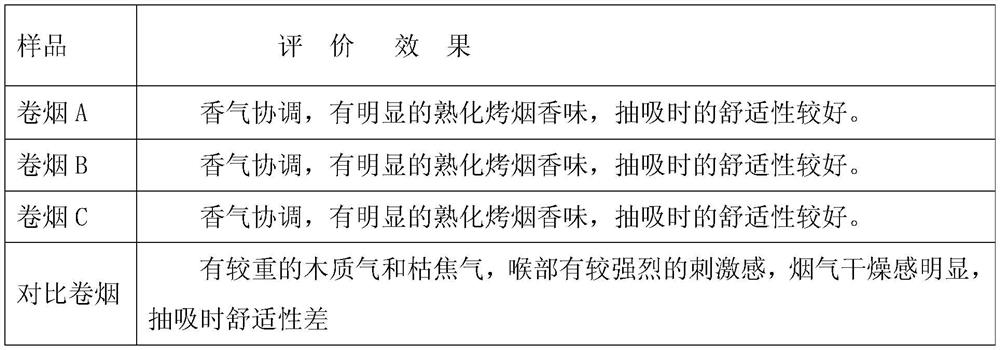

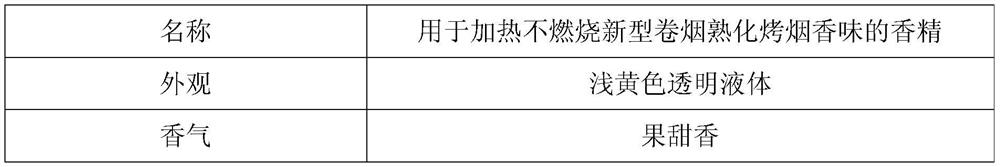

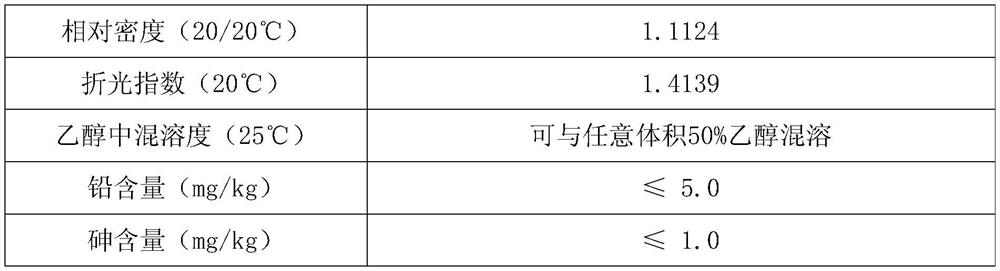

[0039] Example 1: A cured flue-cured tobacco aroma and flavor used in heat-not-burn cigarettes, the specific preparation steps are as follows: 42.53 parts of ethanol, 0.05 parts of fennel oil, 0.3 parts of chamomile oil, and 0.4 parts of ethyl maltol in the raw materials , 0.008 parts of guaiacol, 0.2 parts of 5-methylfurfural, 0.005 parts of 2-acetylpyrazine, 0.007 parts of 2,3-dimethylpyrazine, 3.5 parts of special Yunyan essential oil, 3.0 parts of special Virginia tobacco leaf essential oil, Add 50 parts of glycerin into the stirring container in order, mix and stir for 2-4 hours, stand still for 24-48 hours, use a filter membrane with a pore size of 0.8 microns to filter out the sediment and obtain a filtrate with a relative density of 1.05-1.25. Flavor used for the aroma of cured flue-cured tobacco in heat-not-burn new cigarettes.

[0040] The essence prepared in Example 1 for the aroma of cured flue-cured tobacco in heat-not-burn cigarettes was diluted 6 times with 70% ...

Embodiment 2

[0041] Example 2, an essence for the aroma of cured flue-cured tobacco in heat-not-burn cigarettes, the specific steps are as follows: 45.658 parts of ethanol, 0.03 parts of fennel oil, 0.2 parts of chamomile oil, 0.8 parts of ethyl maltol, 0.004 parts of guaiacol, 0.3 parts of 5-methylfurfural, 0.004 parts of 2-acetylpyrazine, 0.004 parts of 2,3-dimethylpyrazine, 4 parts of special Yunyan essential oil, 4 parts of special Virginia tobacco leaf essential oil, glycerin 45 parts, put into the stirring container in order, stir for 2-4 hours after mixing, stand still for 24-48 hours, use a filter membrane with a pore size of 0.8 micron to filter out the sediment to obtain a filtrate with a relative density of 1.05-1.25, which is the used It is an essence for the aroma of cured flue-cured tobacco in heat-not-burn new cigarettes.

[0042] Dilute the cured flue-cured tobacco flavor essence prepared in Example 2 and used in heat-not-burn cigarettes by 6 times with 70% ethanol, spray i...

Embodiment 3

[0043] Example 3, an essence for the aroma of cured flue-cured tobacco of a new type of heat-not-burn cigarette. The specific steps are as follows: 41.766 parts of ethanol, 0.02 parts of fennel oil, 0.1 part of chamomile oil, 0.7 parts of ethyl maltol, 0.002 parts of guaiacol, 0.4 parts of 5-methylfurfural, 0.006 parts of 2-acetylpyrazine, 0.006 parts of 2,3-dimethylpyrazine, 2.5 parts of special Yunyan essential oil, 4.5 parts of special Virginia tobacco leaf essential oil, glycerin 50 parts, put into the stirring container in order, stir for 2-4 hours after mixing, stand still for 24-48 hours, use a filter membrane with a pore size of 0.8 micron to filter out the sediment to obtain a filtrate with a relative density of 1.05-1.25, which is the used It is an essence for the aroma of cured flue-cured tobacco in heat-not-burn new cigarettes.

[0044] Dilute the cured flue-cured tobacco flavor essence prepared in Example 3 and used in heat-not-burn cigarettes by 6 times with 70% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com