Clear water concrete clear seam strip capable of not being easily damaged during demoulding

A technology of fair-faced concrete and exposed joints, which is applied in the processing of formwork, formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of fair-faced concrete not being able to achieve smooth surfaces and smooth lines, increasing costs, etc. problem, to achieve the effect of retaining the decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

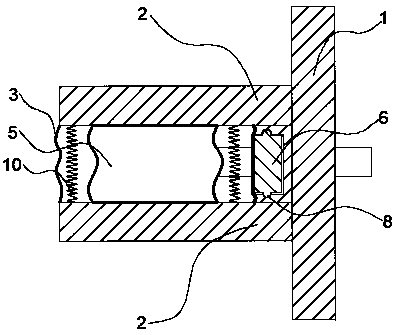

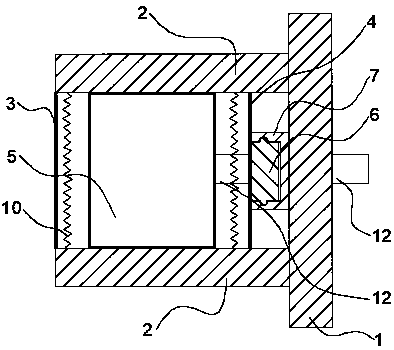

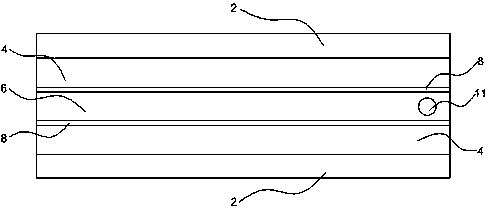

[0021] Reference attached Figure 1 to 5 ; The open seam strips of fair-faced concrete, which are not easy to damage the open seams when demolding, are installed on the formwork 1 and used to form open seams during the construction of fair-faced concrete, including two oppositely arranged open seam forming plates 2, set The end forming belt 3 and the inner connecting belt 4 between the two open seam forming plates 2 are fixed on the inner connecting belt 4 by the expansion bladder 5 which expands the two open seam forming plates 2 by inflating with gas or liquid The slide 6 and the slide groove 7 fixed on the template 1 and matched with the slide 6; in operation, the expansion bag 5 can be filled with air by an air compressor to expand.

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com