Bridge connection type packer for testing crack caused by hydraulic pressure of minor-diameter rock

A hydraulic fracturing and packer technology, applied in sealing/isolation, production fluid, wellbore/well components, etc., can solve problems such as high-pressure liquid and test equipment installation, equipment diameter is too large, etc., to achieve structural Simple, easy-to-assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

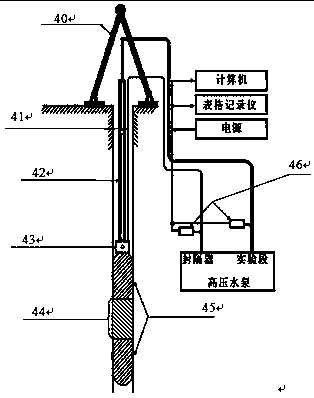

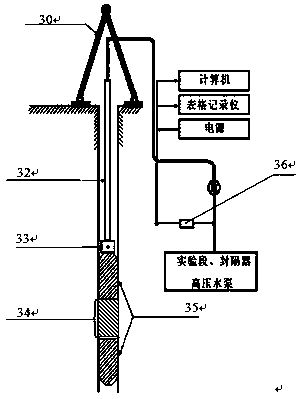

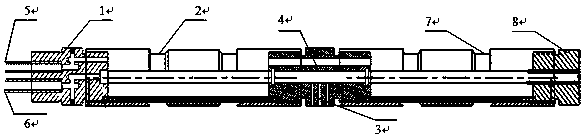

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 3-7 As shown, a bridge-type packer for small-diameter rock mass hydraulic fracturing test of the present invention includes a double-circuit installation rod connector 1, an upper packer 2, a connector 4 with a water spray hole 3, It consists of a lower packer 7 and a lower plug 8; the double-circuit installation rod connector 1, the upper packer 2, the connector 4 with the water spray hole 3, the lower packer 7 and the lower plug 8 are tightly closed in sequence connected.

[0029] In the small-diameter rock mass hydraulic fracturing test bridge packer, the material of the double-circuit installation rod connector 1 is 304 stainless steel, and there are threads at both ends, which are respectively connected to the double-circuit installation rod and the upper packer. The packer inlet hole 5 of the connection head 1 of the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com