Connector with integrated swivel

A technology of rotary joints and connectors, applied in the direction of bearings, connections, pivot connections, etc. of rotary motion, can solve the problems of complicated installation and time-consuming, and achieve the effect of avoiding premature destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

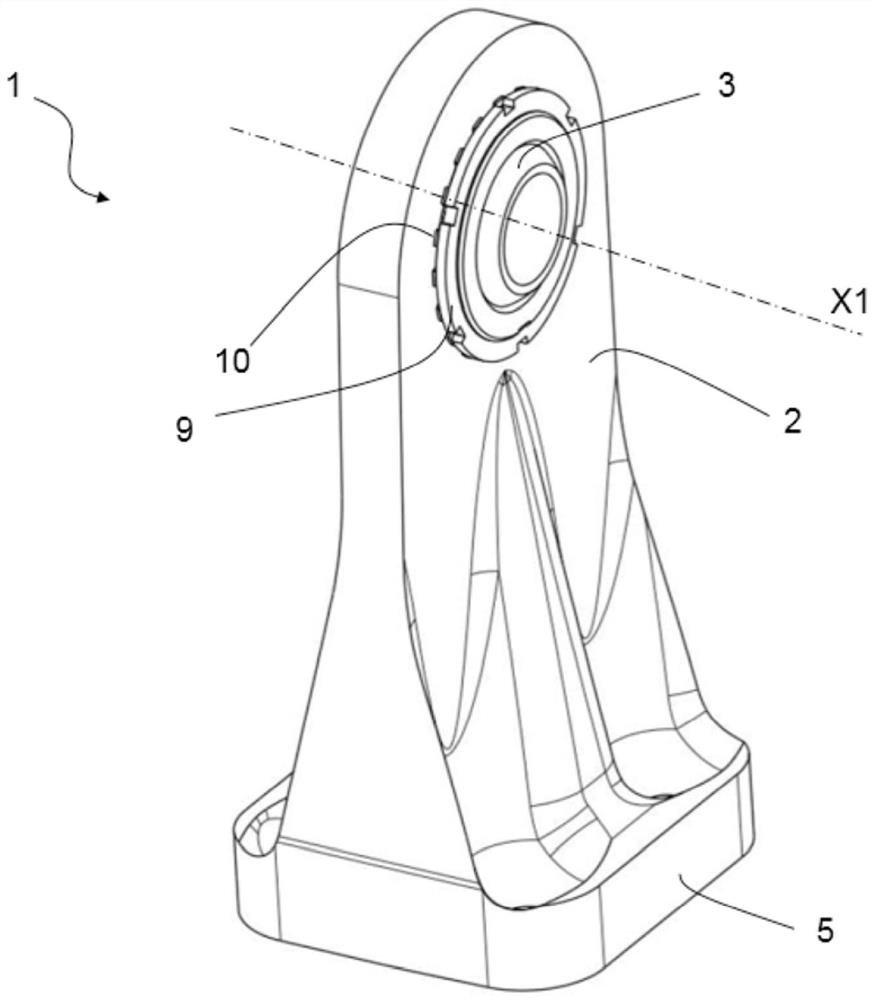

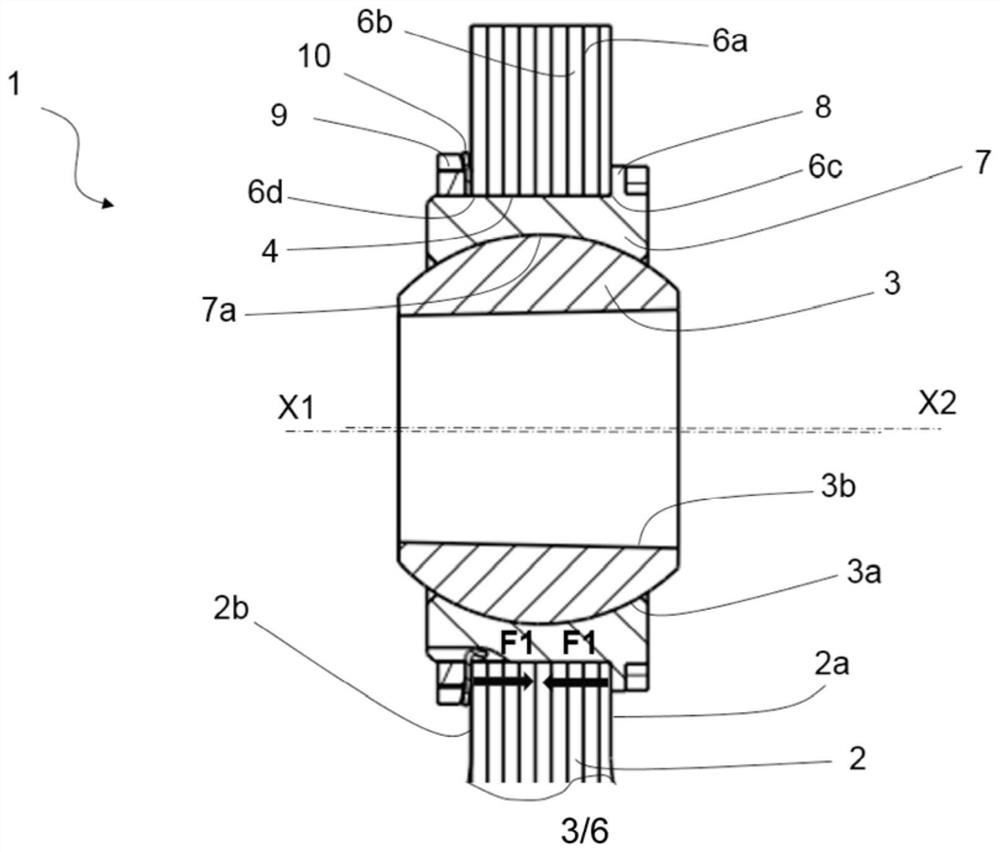

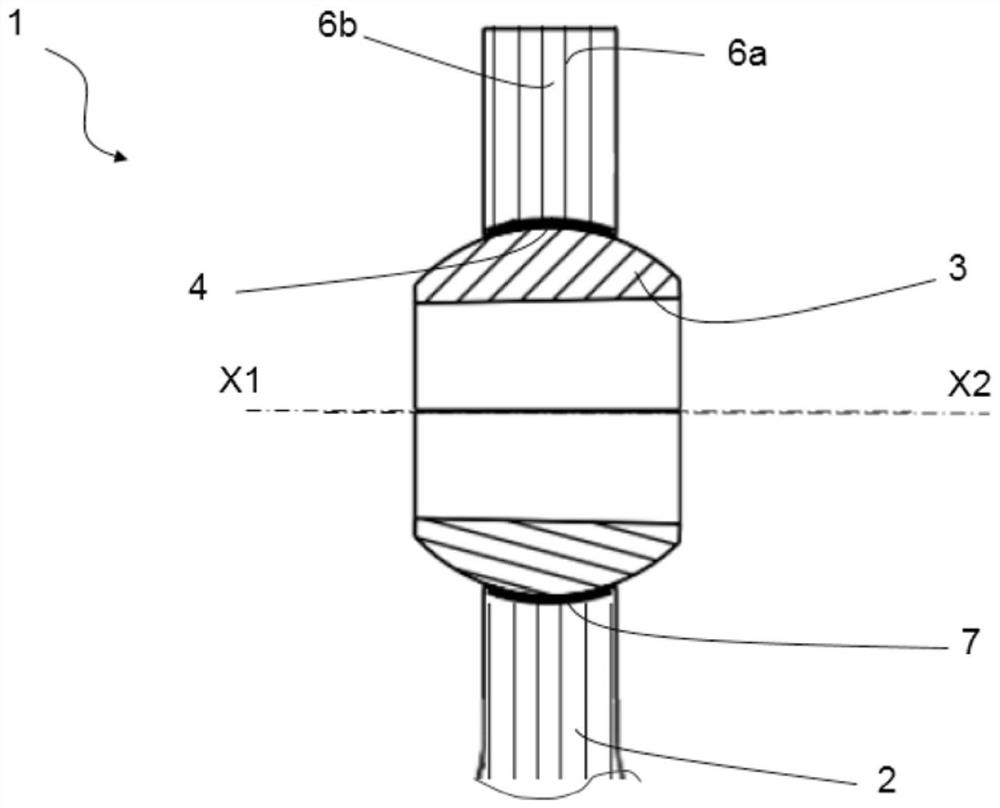

[0027] figure 1 and figure 2 A connector 1 is shown comprising a body 2 with a composite material comprising reinforcing fibres embedded in a plastic matrix 6b. These fibers are advantageously made of carbon fibers, but can also be made of another material such as glass. The plastic matrix 6b is made of a thermosetting resin (eg epoxy resin), but other materials such as thermoplastic resin such as PA 66 can be used.

[0028] The connector 1 also comprises a fastening area for the first member (not shown) to be connected, eg in the form of a base 5 . The means (not shown) for securing the first member to the connector 1 may take the form of screws or rivets.

[0029] The body 2 of the connector 1 comprises a housing 4 with an axis X1 which receives a mounting ring 7 . The mounting ring 7 carries the rotary joint 3 with the axis X2 in its hole.

[0030] The swivel 3 serves as a fastening area for connecting the second member (not shown) with the connector 1 .

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com