Wetting-drying-cycle mudstone slaking test equipment capable of providing true stress conditions

A technology of real stress and test equipment, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems that are difficult to meet the real mechanical conditions of reservoir bank mudstone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

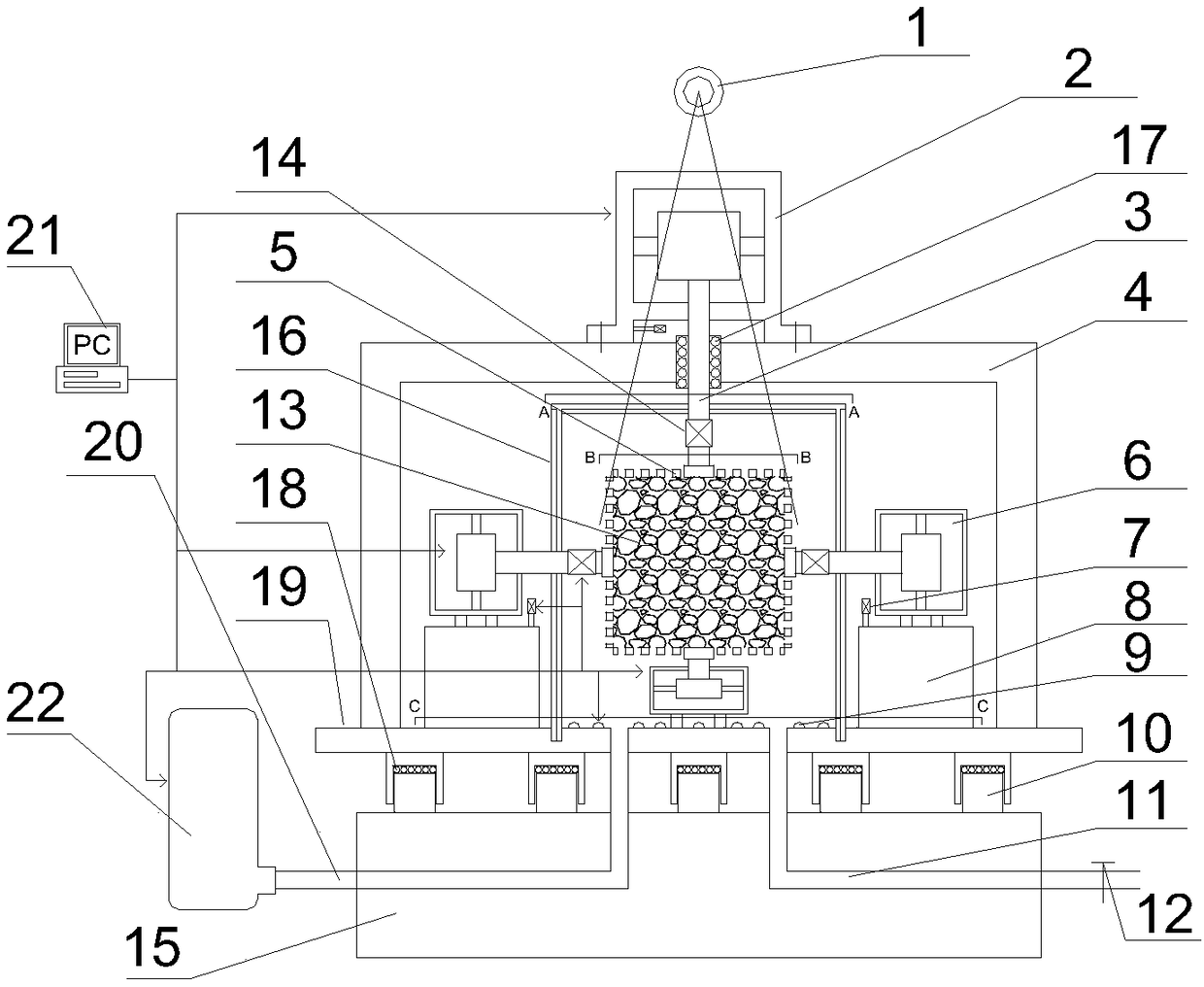

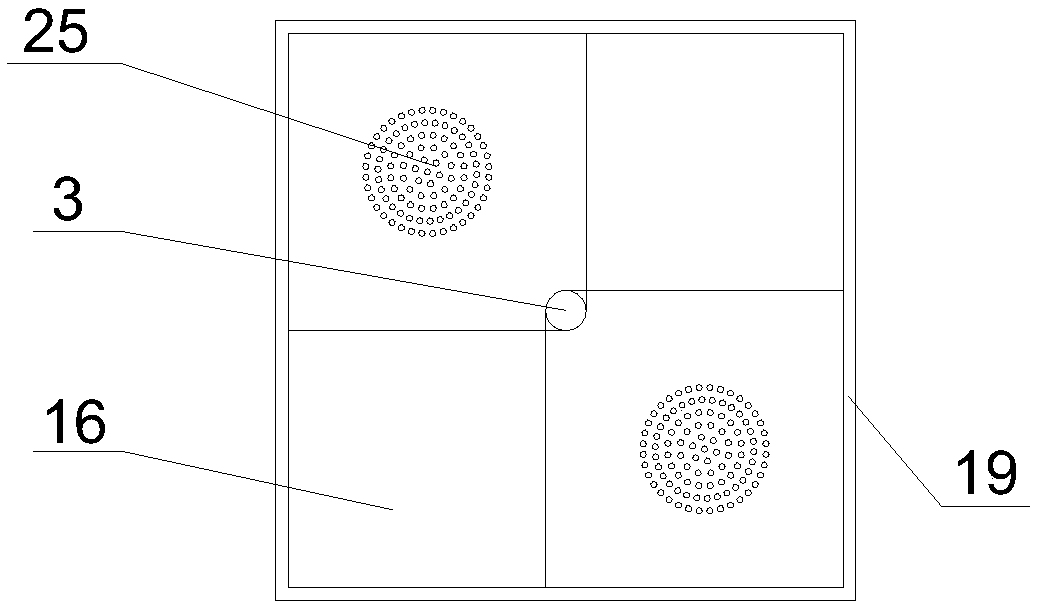

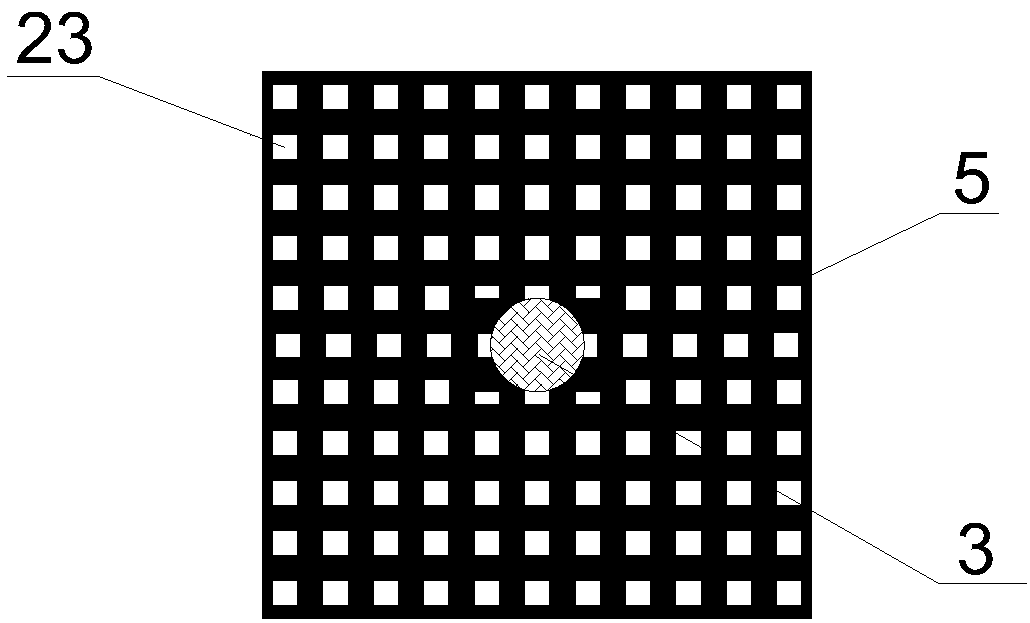

[0024] Please refer to Figure 1 to Figure 5 , the embodiment of the present invention provides a mudstone dry-wet cycle disintegration test equipment that provides real stress conditions, including a base 15 and a test platform 19, a test box 5 and a test box cover 16.

[0025] Several straight slide rails 10 are laid on the upper surface of the base 15, and sliding balls 18 are installed on the slide rails, and the test platform 19 is placed on all the straight slide rails 10 by ball contact, and the test platform 19 A frame column 4 is fixed on it, and a vertical bearing 17 is installed on the frame column 4 , and a stand 24 is provided on the test platform 19 .

[0026] The test box cover 16 is a cuboid without a bottom end face and is embedded on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap