Bus bar module and battery pack

A bus bar module and bus bar technology, which is applied to battery pack components, batteries, and battery packs with several batteries at the same time, to achieve the effect of preventing deterioration and preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

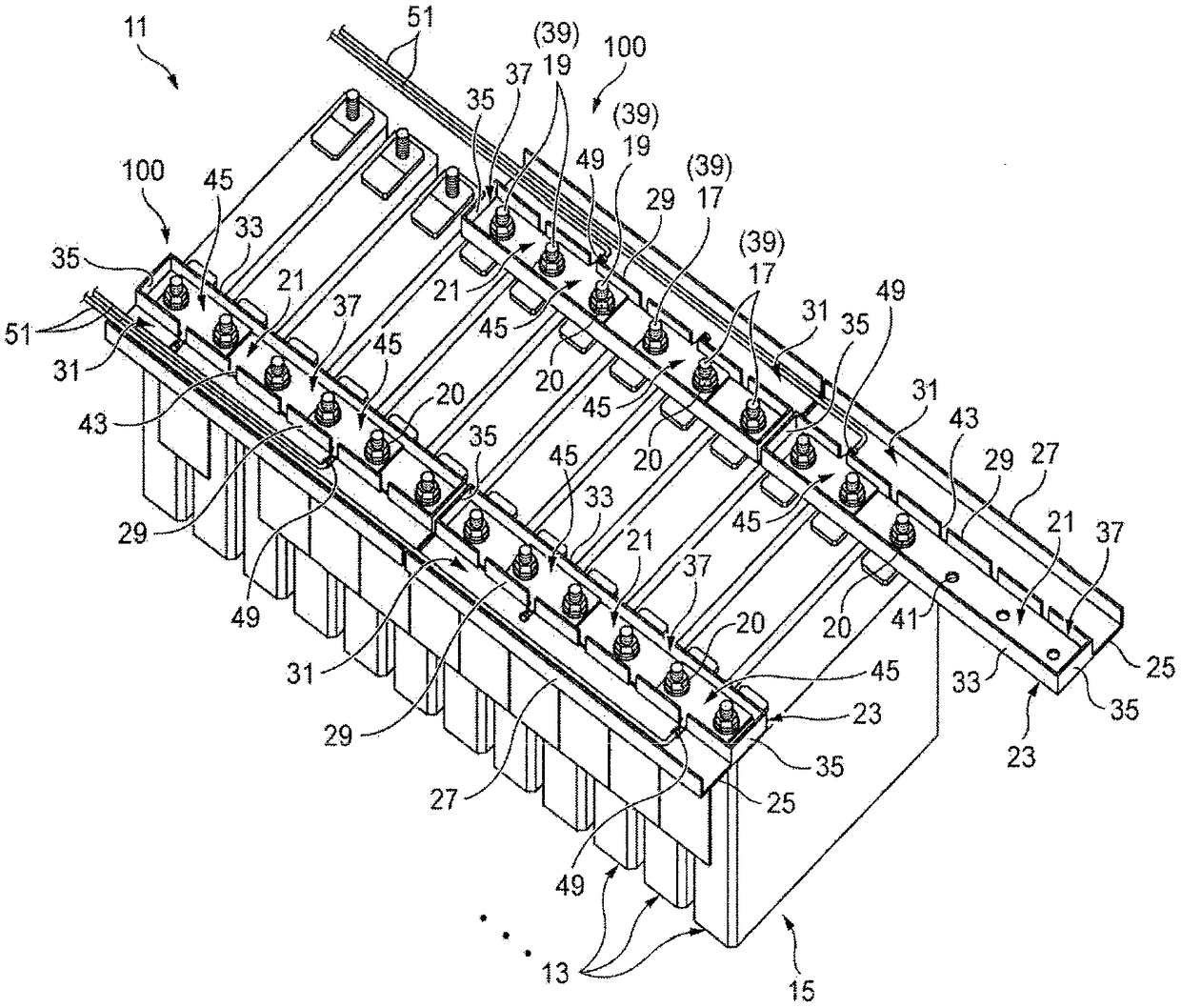

[0038] figure 1 is a perspective view illustrating a main part of the battery pack 11 to which the bus bar module 100 according to the embodiment of the present invention is mounted.

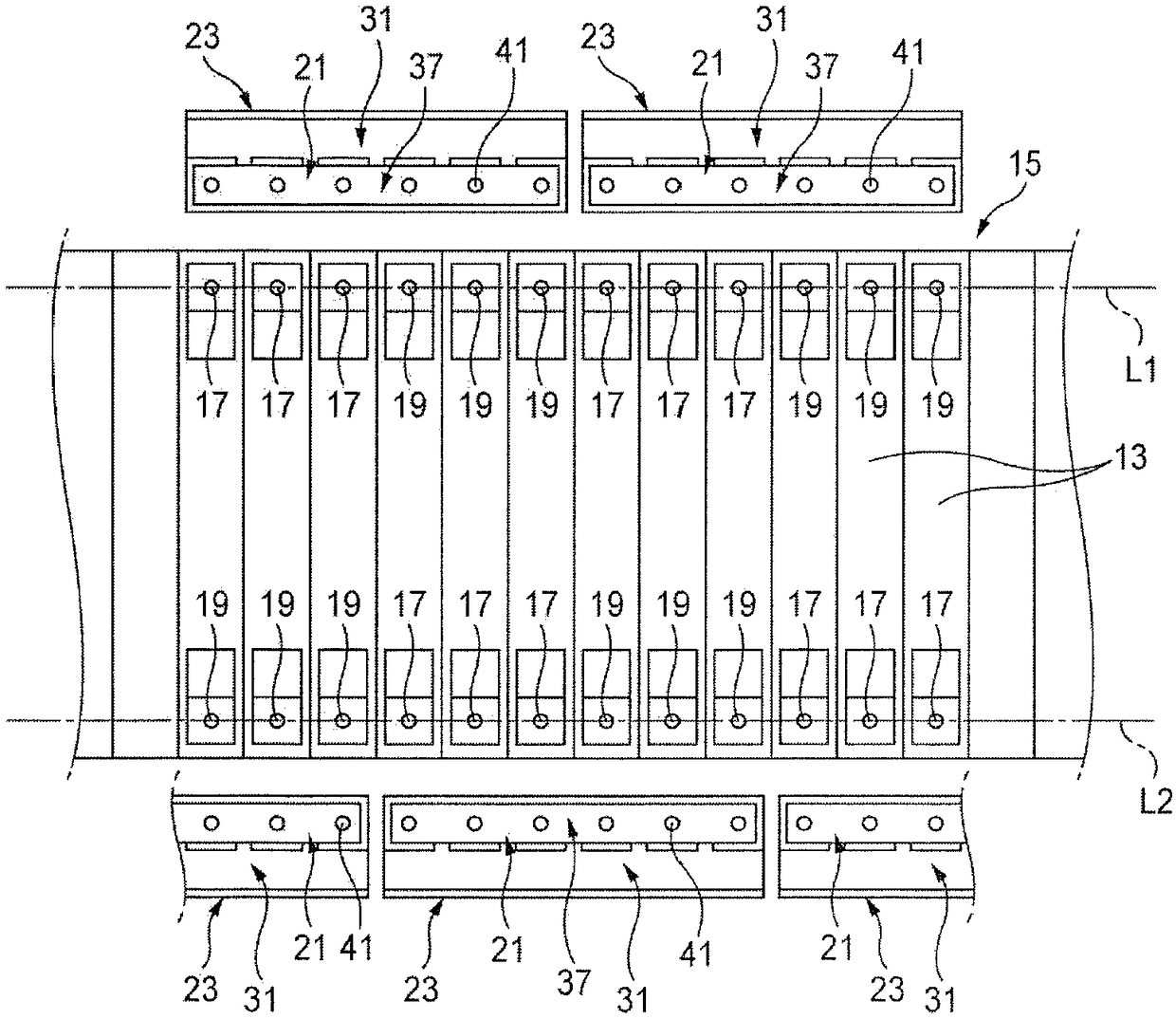

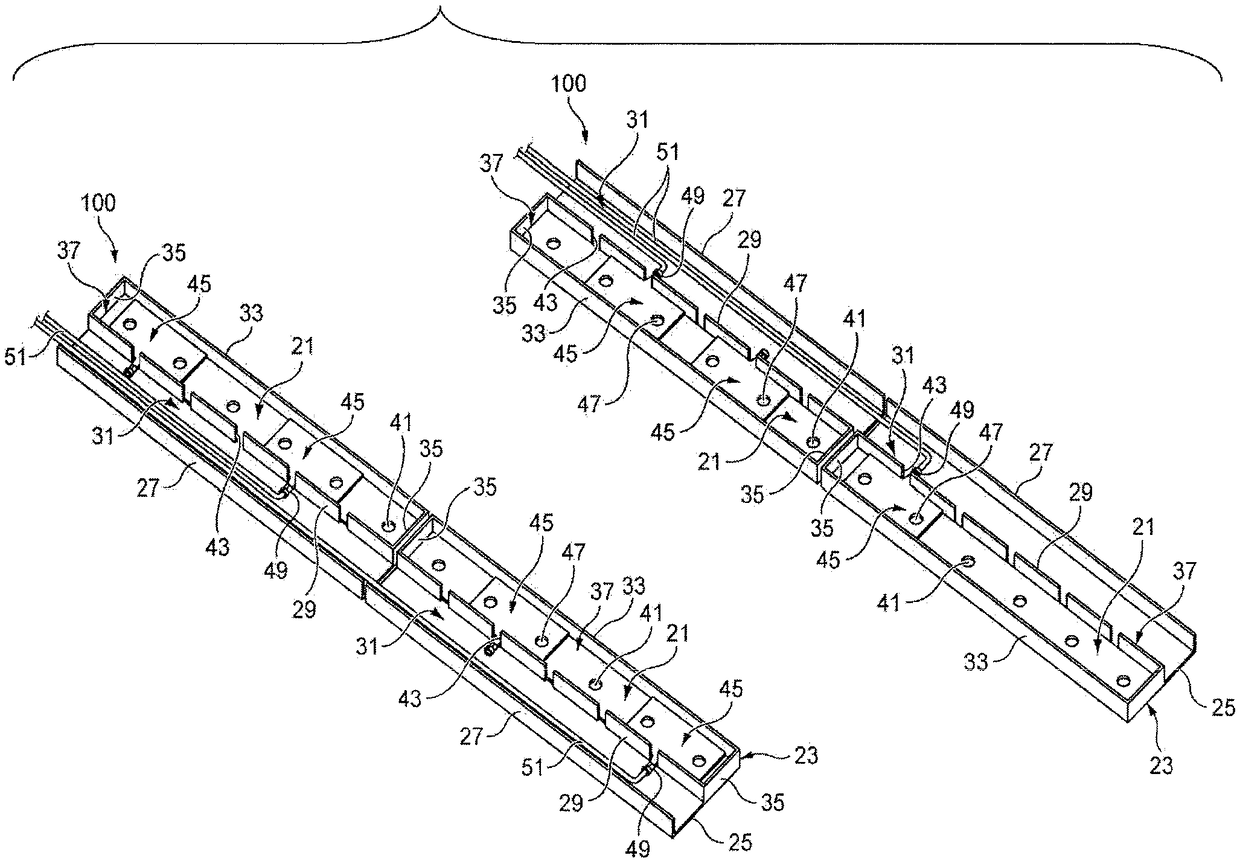

[0039] The bus bar module 100 according to this embodiment is installed in an assembled battery 15 in which a plurality of single cells 13 are arranged side by side with each other. The bus bar module 100 and the assembled battery 15 constitute the battery pack 11 .

[0040] In this embodiment, the unit cell 13 is formed in a plate shape, and is provided with a positive terminal 17 and a negative terminal 19 at both ends in the length direction in an upper end surface which is a rectangular flat surface. In this embodiment, the positive terminal 17 and the negative terminal 19 are formed in a bolt shape, but the present invention is not limited thereto. The single cells 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com