Infrared tomato peeling device

A peeling device, infrared technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of unguaranteed food safety, complicated production process, low labor efficiency, etc., to ensure the success rate of peeling, Avoid heating dead angle, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

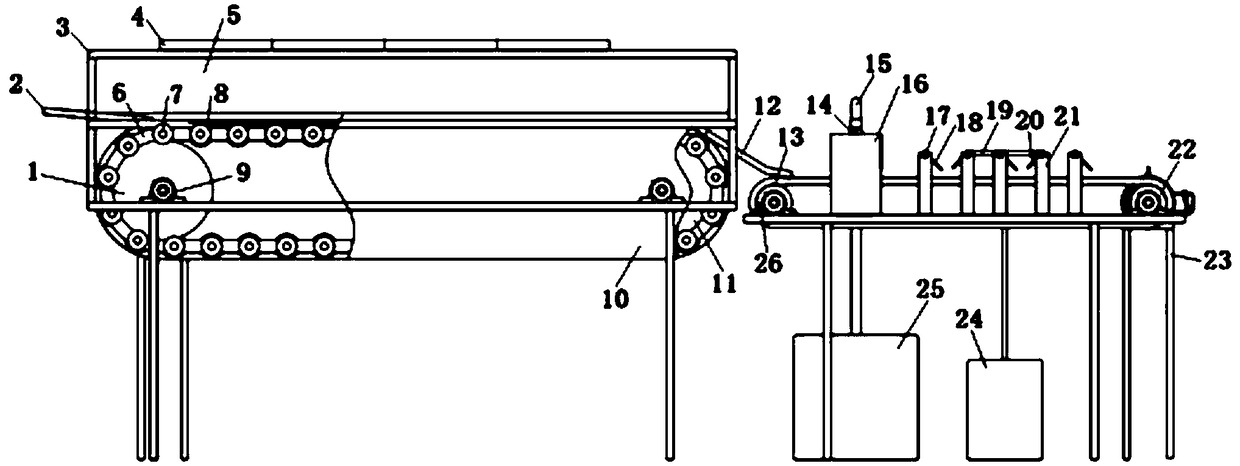

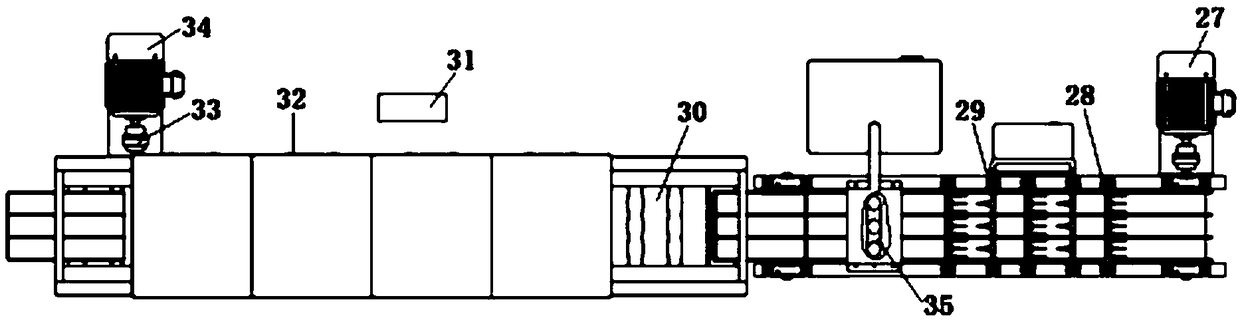

[0030] The invention provides a kind of infrared tomato peeling device, see figure 1 and figure 2 , including infrared tumbling conveying device and quick cooling blowing and skinning device:

[0031] The infrared tumbling conveying device includes a feed port 2, and also includes a conveying roller driving wheel 1 driven by a conveying roller motor 34, and the transmission between the conveying roller driving wheel 1 and the conveying roller driven wheel 11 is realized through a conveying chain 6, and the conveying roller driving wheel 1 The bearing with seat 9 is installed on the mounting frame of the fixed infrared heating device, and the bearing with seat 9 is connected with the conveying roller motor 34 through a shaft coupling 33 . A group of conveying rollers 30 are arranged on the conveying chain 6, bearings are installed at both ends of the conveying roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com