Orthodontic tray and manufacturing method thereof

A manufacturing method and tray technology, which is applied in the field of indirect bonding and orthodontic correction, can solve problems such as manual errors, high difficulty, and affecting the effect of orthodontic treatment, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

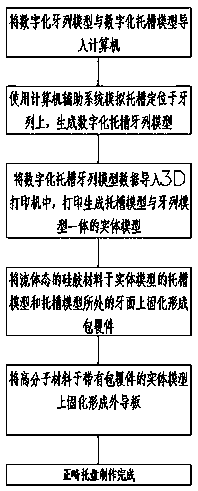

Method used

Image

Examples

specific Embodiment 1

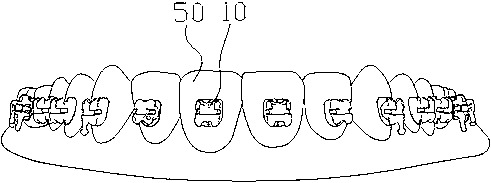

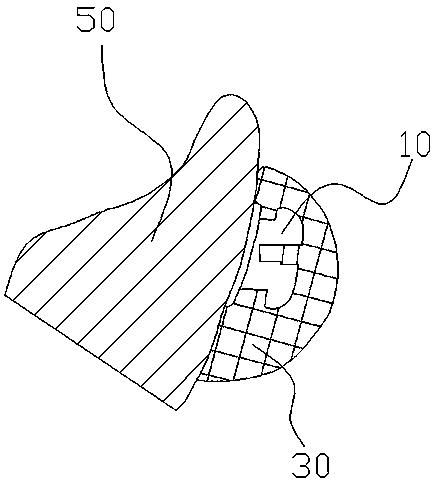

[0050] Different orthodontic trays 20 are produced according to the arrangement of each person's dentition. The orthodontic tray 20 includes an outer guide plate 40 and a cover 30 placed inside the outer guide plate 40. The outer guide plate 40 has a lingual cavity 41, an occlusal cavity 42 and The lip and cheek cavity 43, the inner side of the lip and cheek cavity 43 of the outer guide plate 40 matches the covering part 30, the surfaces of the lip and cheek cavity 43, the lingual cavity 41 and the occlusal cavity 42 are all smooth curved surfaces, the outer guide plate 40 and the dentition Matching, the outer guide plate 40 has a shape similar to the dentition, consistent with the curvature of the dental arch, the outer guide plate 40 is made of a transparent hard mold, and the outer guide plate 40 is a transparent guide plate, and the outer guide plate 40 is vacuumed by the transparent hard mold. Made of compression molding, the hardness of the outer guide plate 40 is relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com