Building garbage treatment device

A technology for processing devices and construction waste, which is applied in the field of construction machinery, can solve problems such as damage to crushing devices, high labor costs, waste of resources, etc., and achieve the effect of solid-liquid separation, avoiding unusable and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

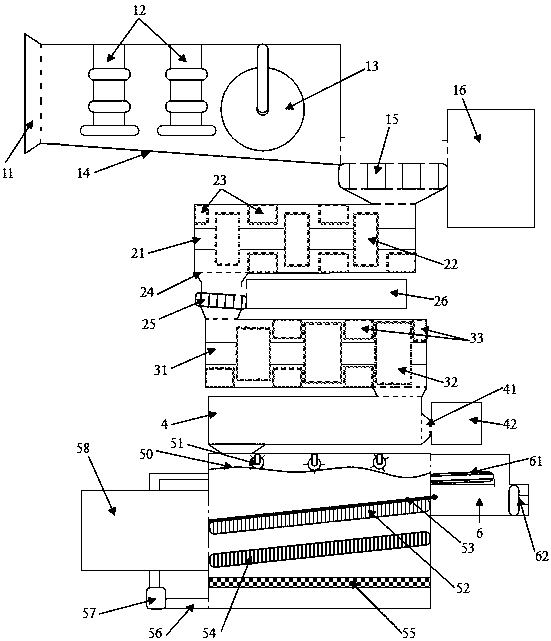

[0032] like figure 1 Shown:

[0033] A construction waste treatment device, including an impact chamber, a large metal collection box, a coarse crushing chamber, a small metal collection box, a fine crushing chamber, a magnetic separation chamber, an iron powder collection box, a water floating separation chamber, a floating object collection chamber and Construction material collection box.

[0034]The impact chamber includes an impact chamber shell, a garbage inlet, an impact hammer, a rolling roller, an impact chamber outlet, a transmission grid and an impact chamber small material outlet; the garbage inlet is arranged on the side wall of the impact chamber shell, It is used to put the construction waste into the impact chamber. There are two impact hammers, which are vertically arranged on the inner top wall of the shell of the impact chamber, and impact and crush the materials entering the impact chamber through downward impact. The rolling roller is set on the inner to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com