Cereal impurity removing and cleaning device and method

A cleaning device and grain cleaning technology, applied in cleaning methods and utensils, liquid cleaning methods, chemical instruments and methods, etc., can solve problems such as incomplete removal of grain impurities, increased input costs, and grain collision damage, etc., to achieve grain Good impurity removal effect, reduce input cost, and ensure thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

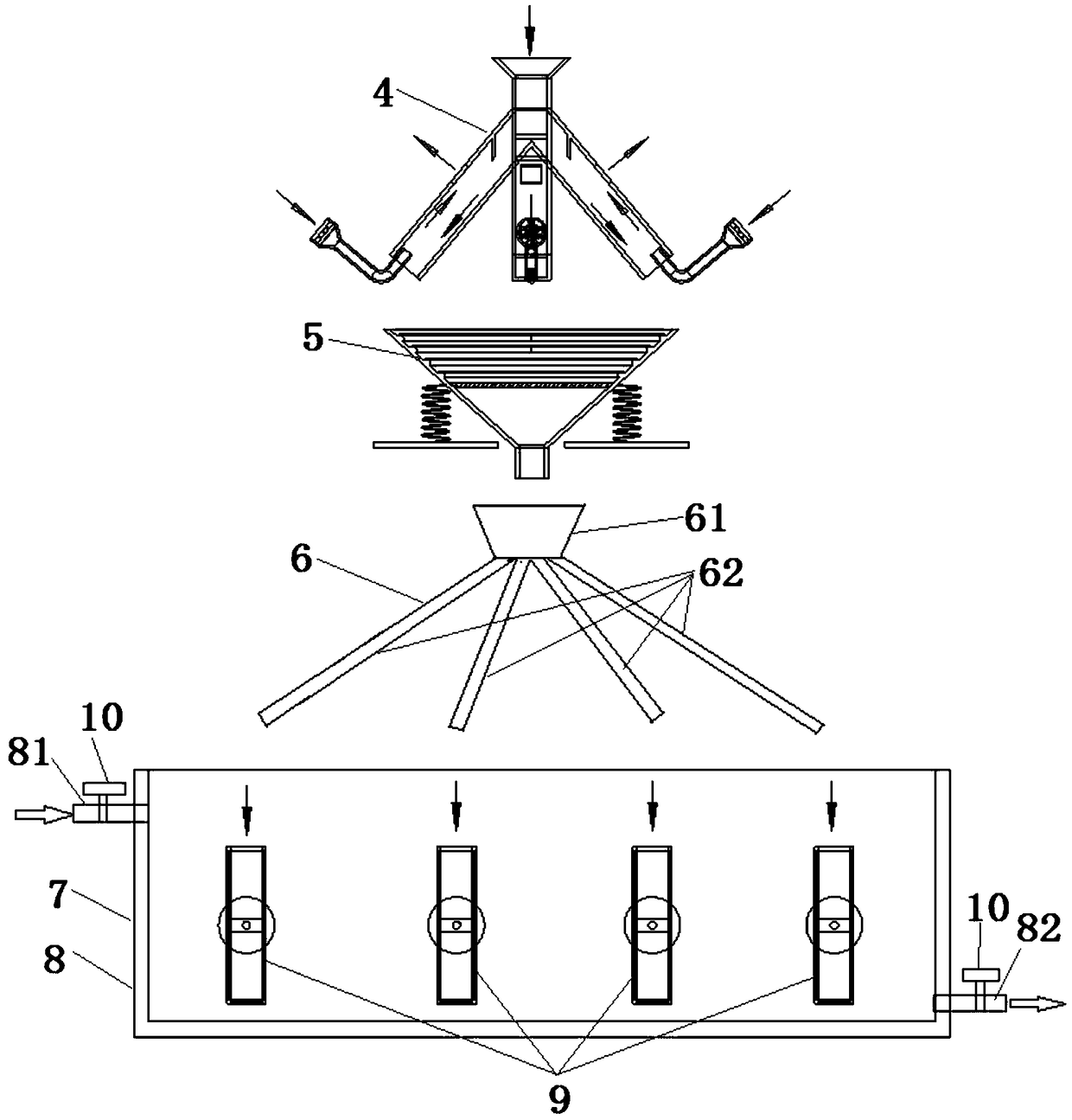

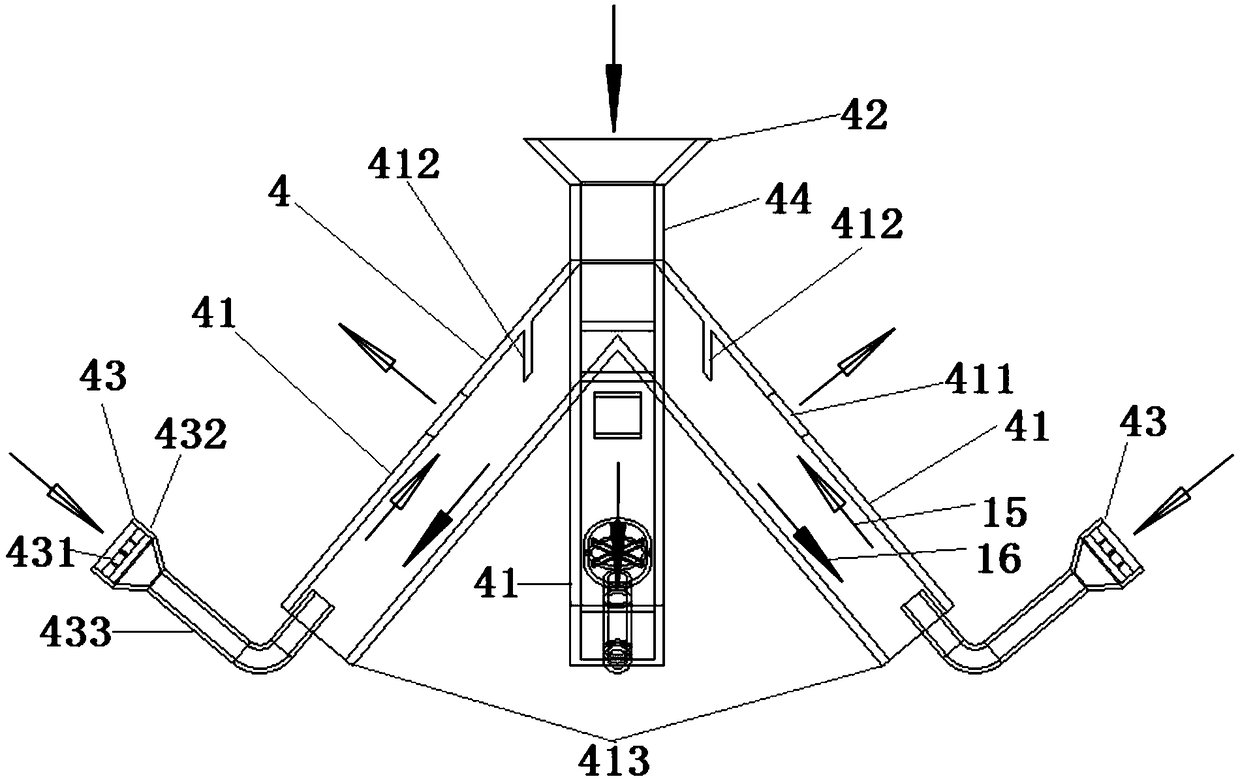

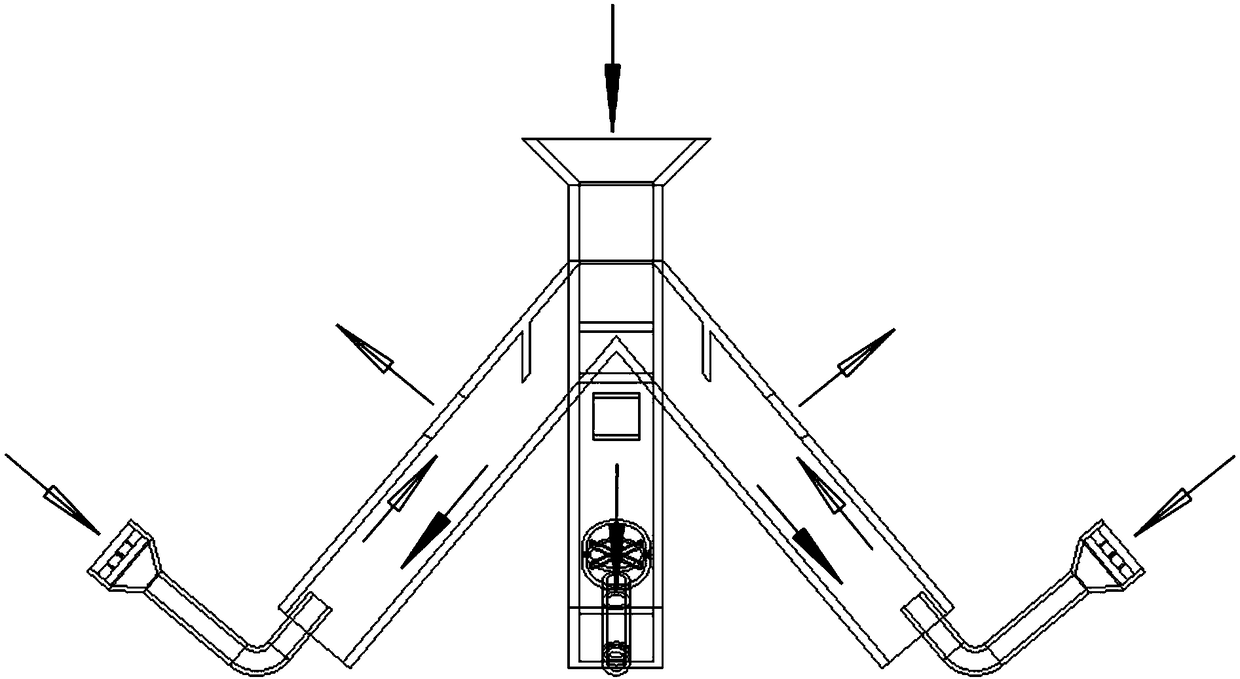

[0035] as attached figure 1 to attach Figure 6 Shown, a kind of grain cleaning device for impurity removal, comprises grain diversion light impurity removal device 4, grain receiving heavy impurity removal device 5, grain splitter 6 and grain cleaning device 7; Described grain diversion light impurity removal device 4 is used for Grain splitting and removal of light impurities in the grain, which has a first feed port 42 and a plurality of first discharge ports 413; the grain receiving heavy impurities removal device 5 is used for the receiving of grain and removing the impurities in the grain weight impurities, it has a second feed port 511 and a second discharge port 512, a plurality of the first discharge port 413 is set corresponding to the second feed port 511; the grain splitter 6 is used for grain The shunt of the grain receiving cover 61 and several shunt pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com