Sheet metal folding production line

A production line and sheet metal technology, applied in the field of hemming equipment, can solve the problems of low degree of automation, low production efficiency and high production cost, and achieve the effects of high machining accuracy, reliable work and automatic operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below by non-limiting embodiment and in conjunction with accompanying drawing, the present invention will be further described:

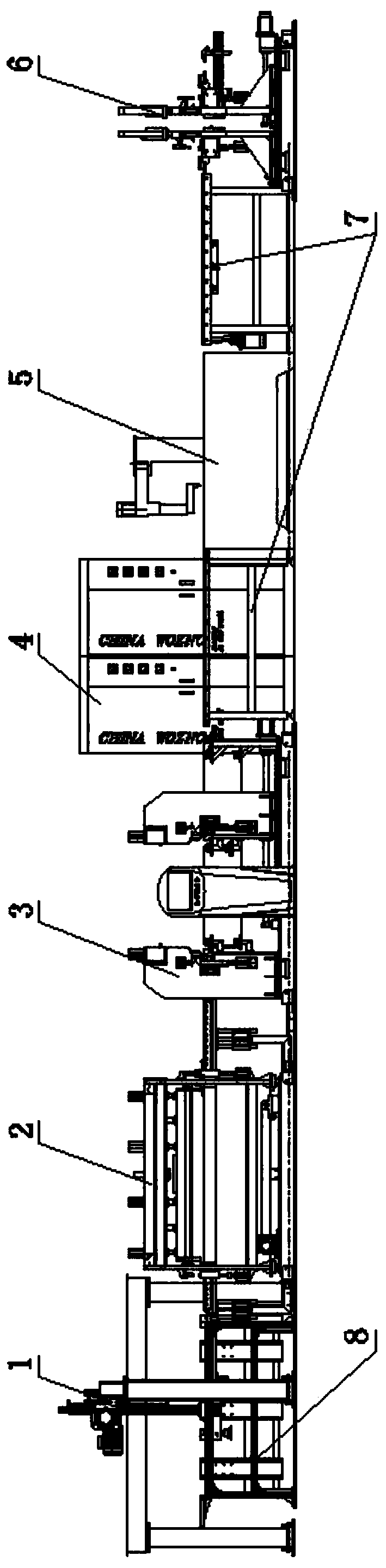

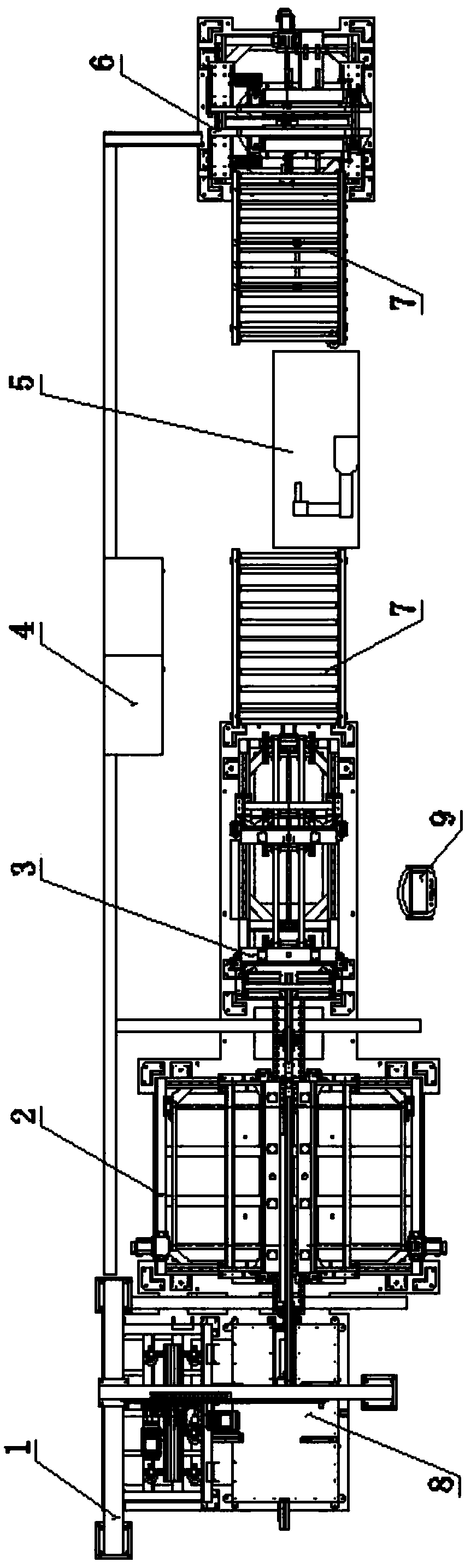

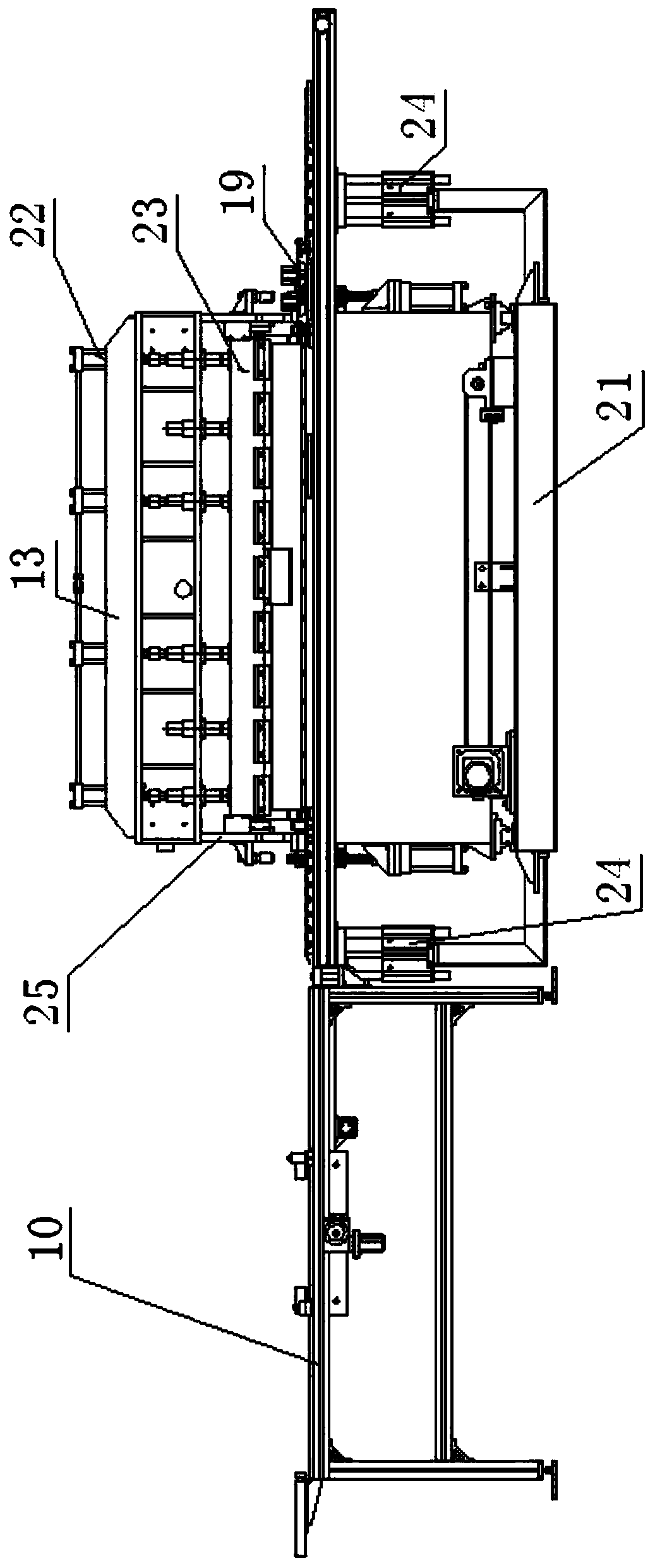

[0029]As shown in the drawings, a sheet metal hemming production line includes a feeding unit 1, a long hemming unit 2, and a short hemming unit 3 arranged in sequence from front to back. In this embodiment, after the short hemming unit 3 The external welding unit 5 and the deep hemming unit 6 are also arranged in sequence. The feeding unit 1 adopts suction cup feeding, which is an existing technology, mainly including a suction cup bracket and a suction cup, the suction cup can move along the crossbeam of the suction cup frame, and the suction cup can be lifted, and the suction cup can absorb the sheet material to be processed and move to a set position. work location. The long hemming unit 2 includes a base A21, on which a long hemming machine I12 and a long hemming machine II13 with the same structure and arranged opposite to each other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com