Case vibrating machine

A technology for a shell shaker and a frame, which is applied in the field of shell shakers, can solve the problems of easy damage, complex structure of the shell shaker, and inability to recover the mold shell, etc., and achieves the effect of improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The accompanying drawings are for illustrative purposes only and cannot be construed as limiting the patent;

[0019] In order to better illustrate this embodiment, some parts in the drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product;

[0020] For those skilled in the art, it is understandable that some well-known structures and descriptions thereof may be omitted in the drawings.

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

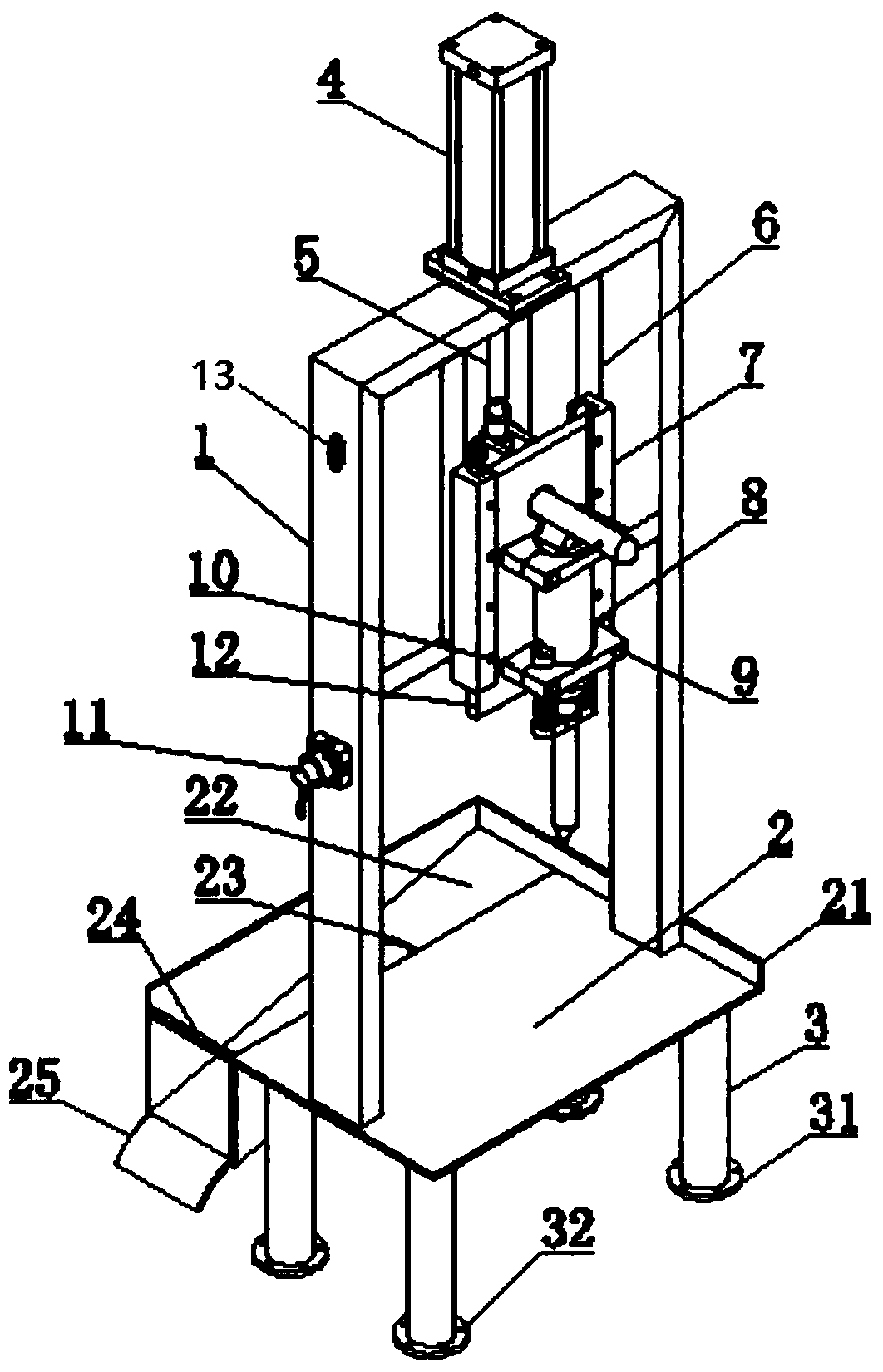

[0022] Please refer to figure 1 As shown, a shell shaker includes a frame 1, the bottom of which is set as a work surface 2, and also includes

[0023] vibration frame 12, which is movably arranged on the frame 1,

[0024] A vibrating rod 8, which is movably arranged on the vibrating frame 12 for removing the shell film (detritus) on the casting by the vibration of the vibrating rod when con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap