Method of connecting metal with carbon fiber composite material

A connection method and technology of composite materials, applied in the field of connection of dissimilar materials

Inactive Publication Date: 2018-12-18

张家港创博金属科技有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The arc joining method widely used in metal materials is not suitable for carbon fiber materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-6

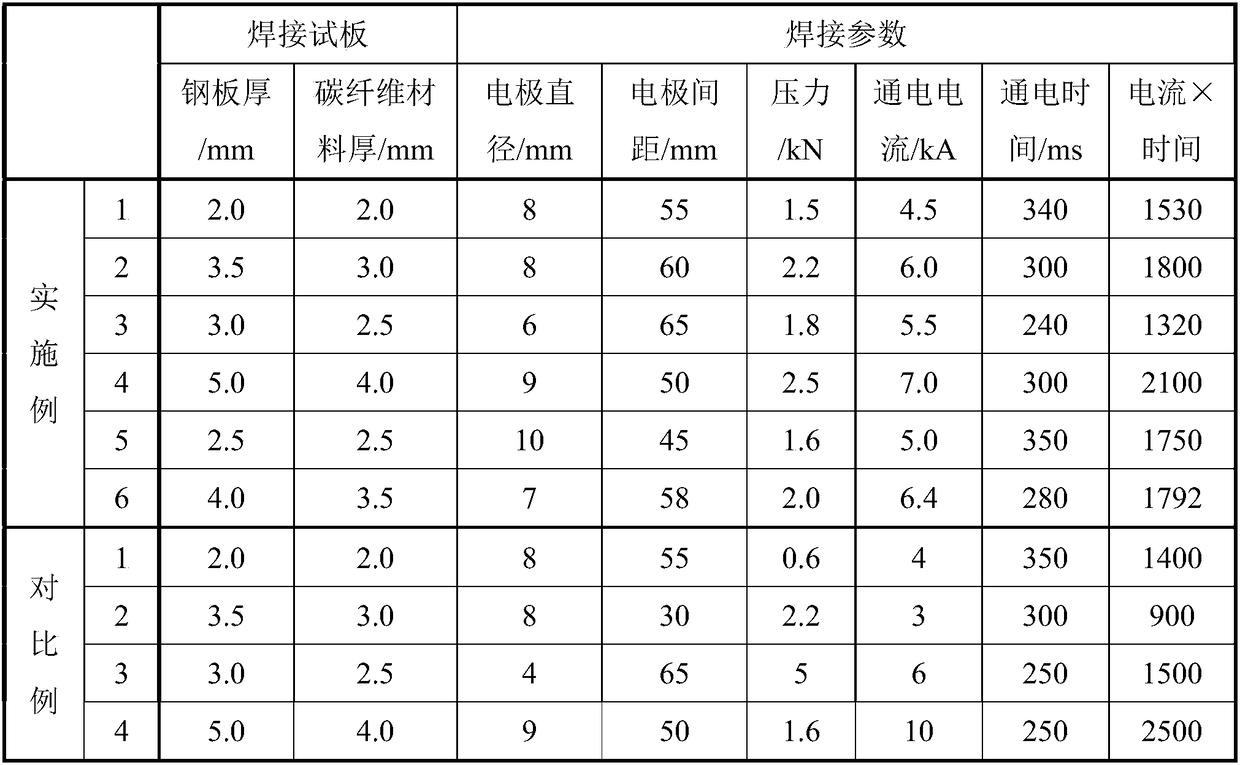

[0037] See Table 1 for the welding plate thickness and welding parameters used in Examples 1-6.

[0038] Silane coupling treatment is carried out on the side where the steel plate is bonded to the carbon fiber.

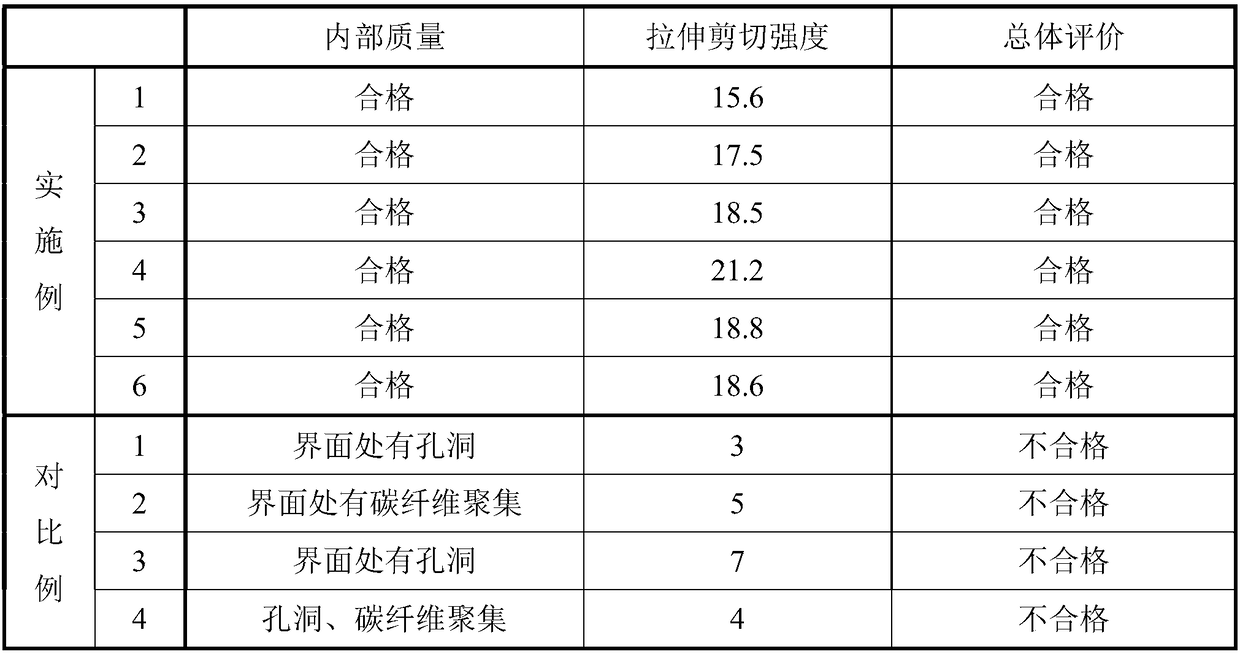

[0039] The results of post-weld quality inspection are shown in Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

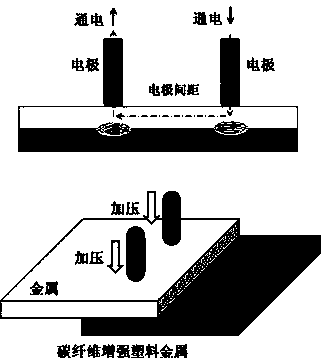

The invention relates to a method of connecting metal with a carbon fiber composite material. A double-electrode spot welding method is conducted on a metal layer, copper electrodes are adopted, the diameter of the contact end of each copper electrode ranges from 6mm to 10mm, the applied pressure ranges from 0.8kN to 3kN, the distance between the electrodes ranges from 40mm to 70mm, the electrodeenergizing current ranges from 4kA to 8kA, and the energizing time ranges from 200ms to 350ms. The materials with the thicknesses smaller than or equal to 5mm can be connected.

Description

technical field [0001] The invention relates to a connection method of metal and carbon fiber reinforced composite material, which belongs to the field of welding technology, in particular to a connection method of dissimilar materials of metal and carbon fiber reinforced composite material. Background technique [0002] Thanks to the advantages of high strength, high toughness and light weight, carbon fiber reinforced composite materials have broad application prospects in the fields of aviation, aerospace, automobiles, machinery and construction. Some applications have been made in aviation, automobile and other fields. But at present, the processing technology of carbon fiber materials, especially the connection technology with other structural metals, is the most restrictive of its industrial application. [0003] The welding of carbon fiber materials and metal materials currently widely used is also a major problem. The arc joining method widely used in metal material...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K11/11B23K11/36B29C65/00B23K103/18

CPCB23K11/11B23K11/36B29C65/00

Inventor 潘鑫朱俊李小宝

Owner 张家港创博金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com