Method for determining ductile-regime grinding of hard and brittle material based on brittle removal proportionality coefficients and surface roughness

A technology of hard and brittle materials and surface roughness, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc. It can solve the problems of small individual differences, lack of judgment indicators, and inaccurate judgment results and other issues to achieve the effect of easy implementation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

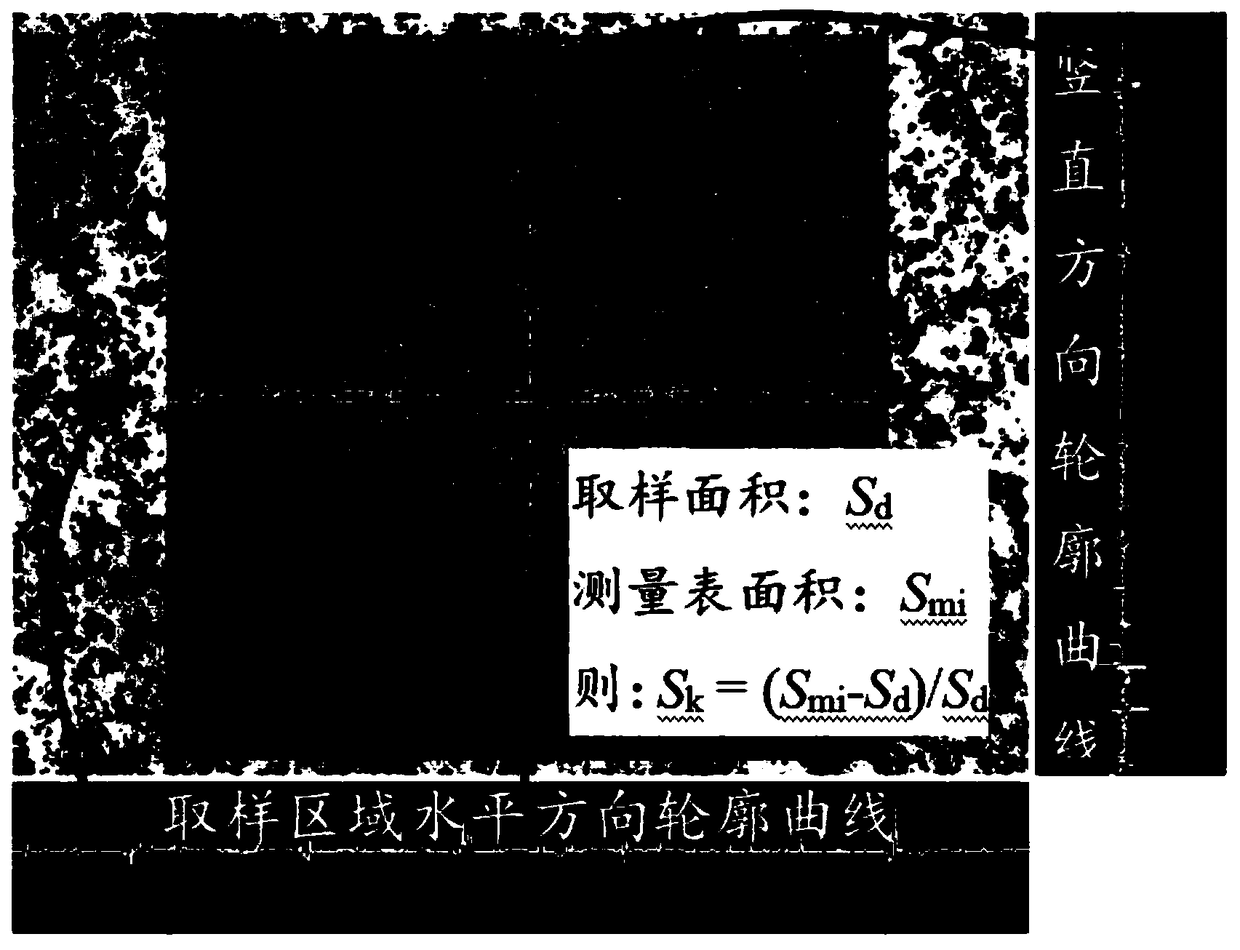

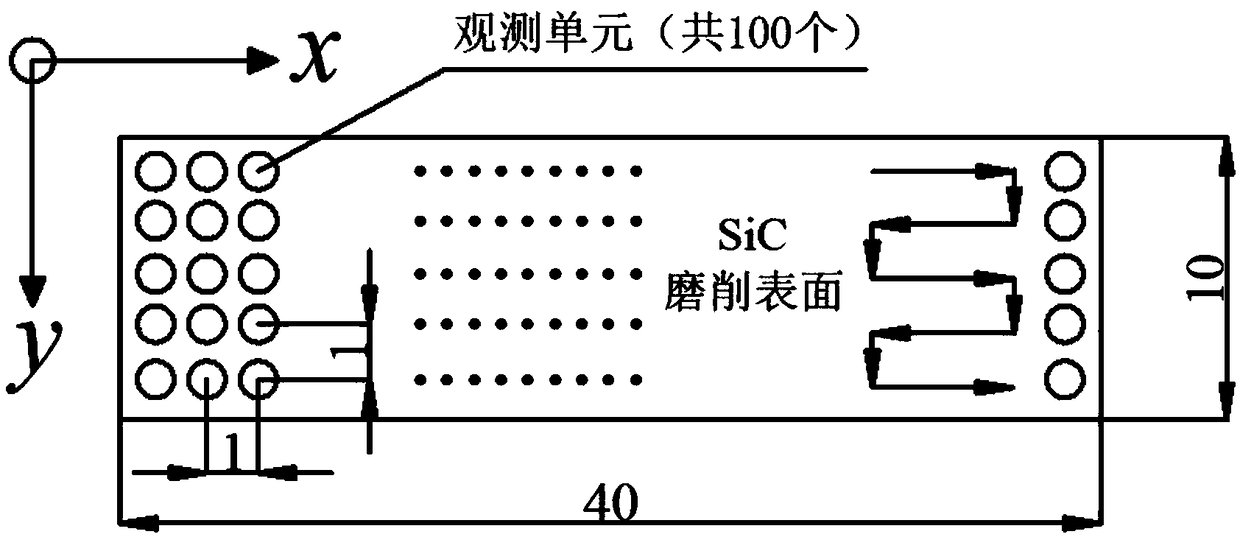

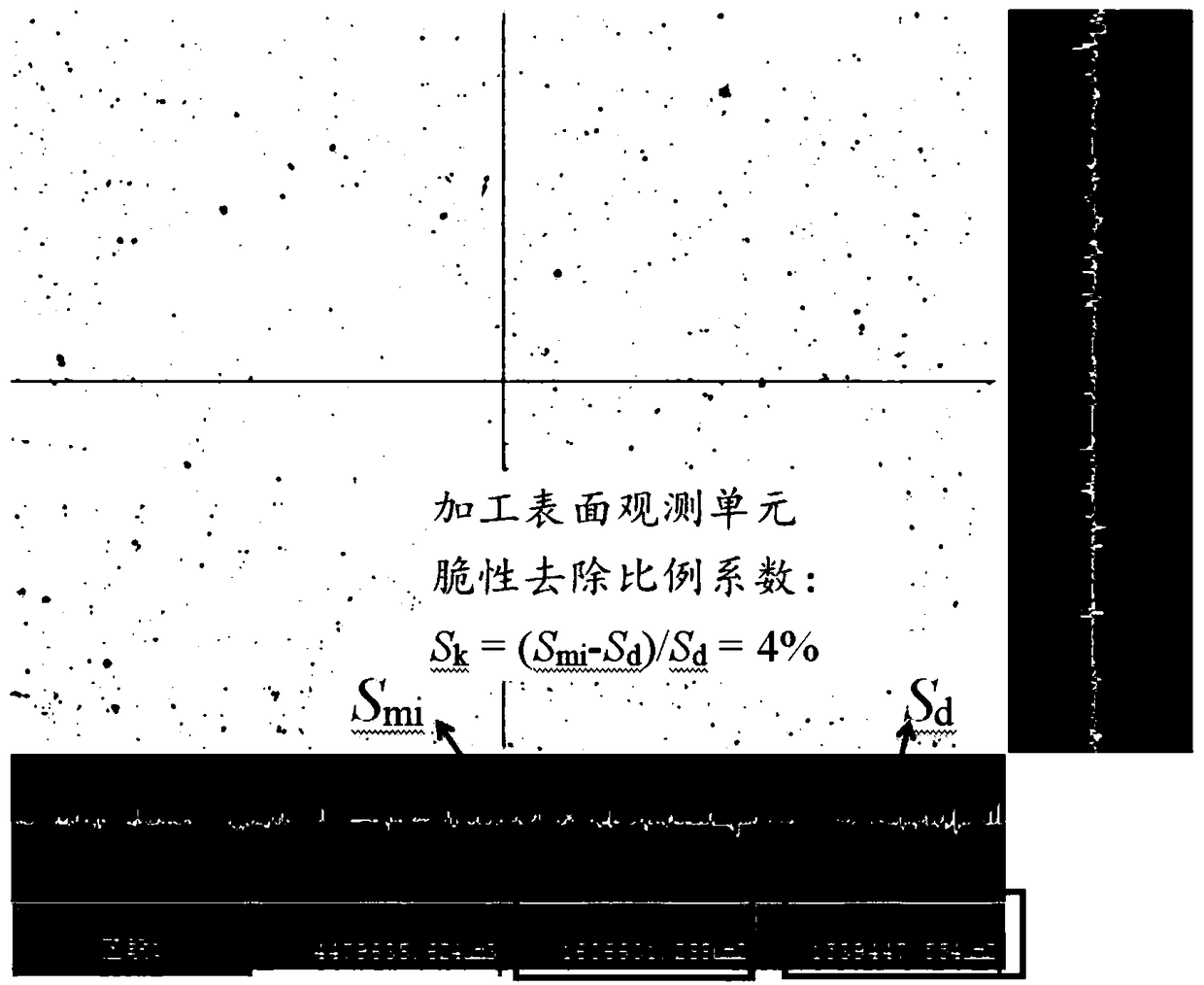

[0028] like Figure 1-Figure 4 As shown, the method for determining the ductility domain grinding of hard and brittle materials based on the brittle removal ratio coefficient and surface roughness provided in this embodiment, and the detection of the grinding surface of hard and brittle materials based on the KeyenceVK-X100 laser three-dimensional shape measurement system, include the following step:

[0029] Step 1: Obtain a grinding surface of a hard and brittle material sample with a surface area greater than 40mm×10mm by grinding or ultrasonic-assisted grinding;

[0030] Step 2: Use grinding, ultrasonic-assisted grinding or other grinding methods to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com