Polishing machine or grinding machine

A grinding machine and polishing machine technology, which is applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., and can solve the problems that cannot be controlled separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

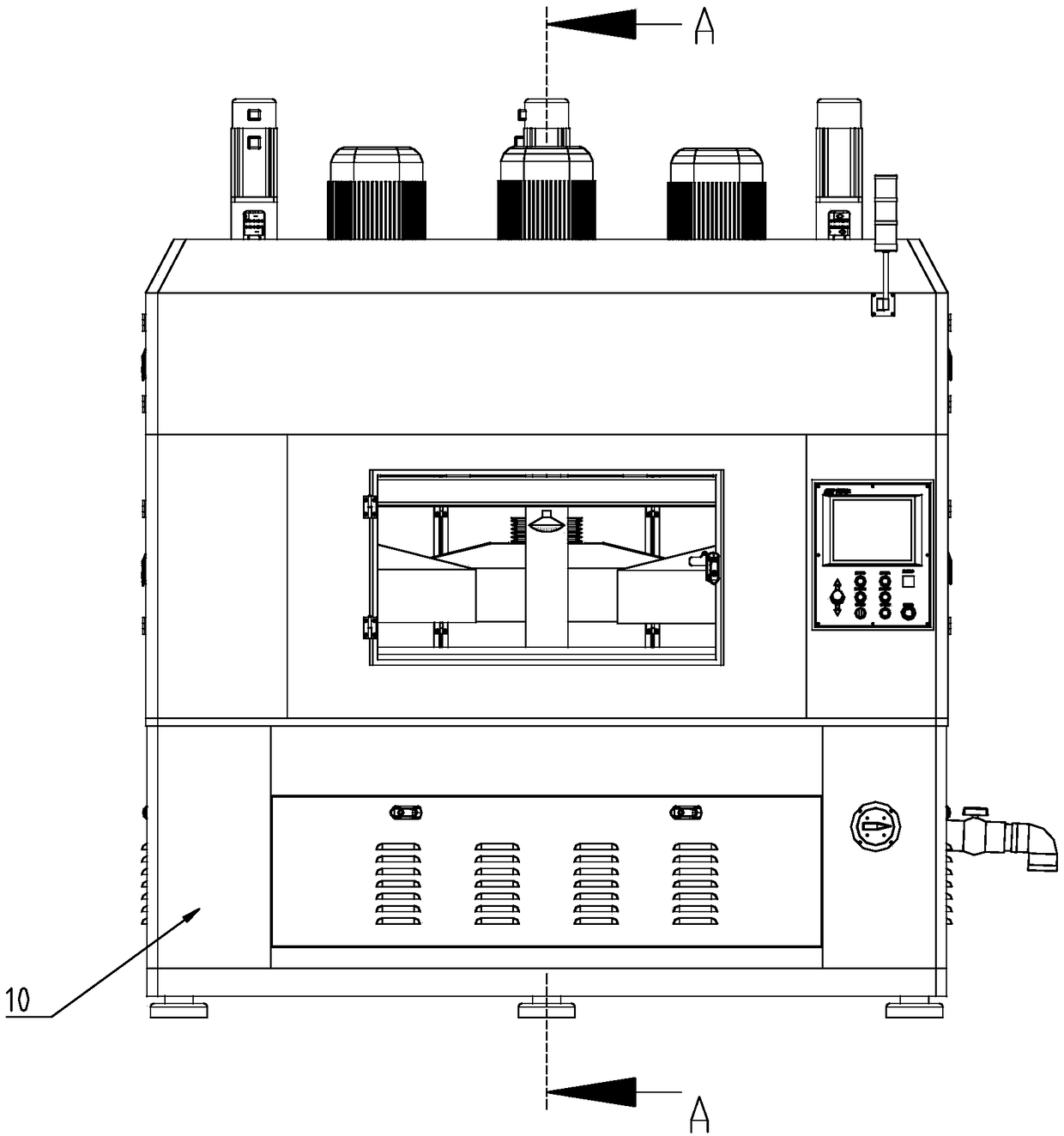

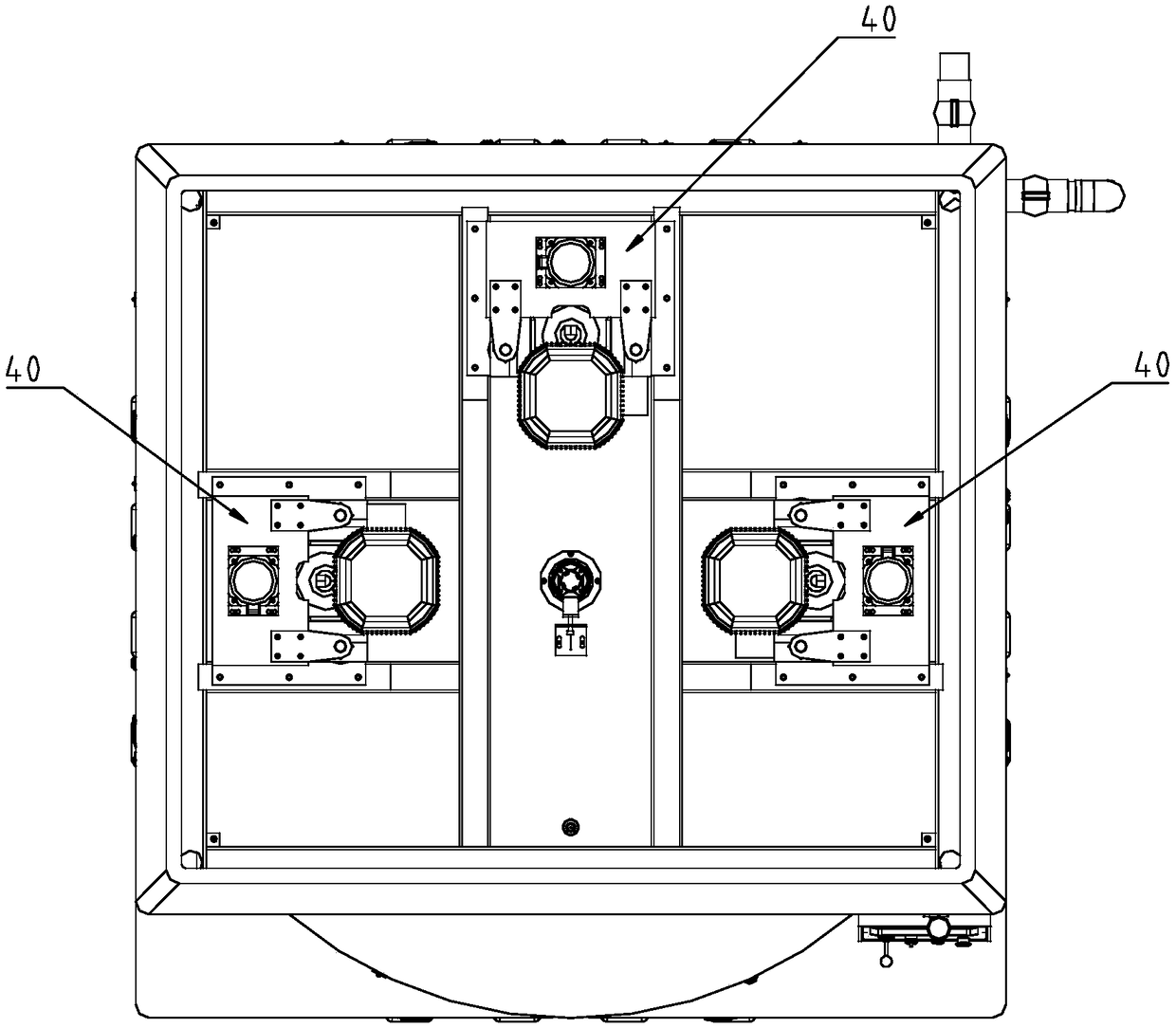

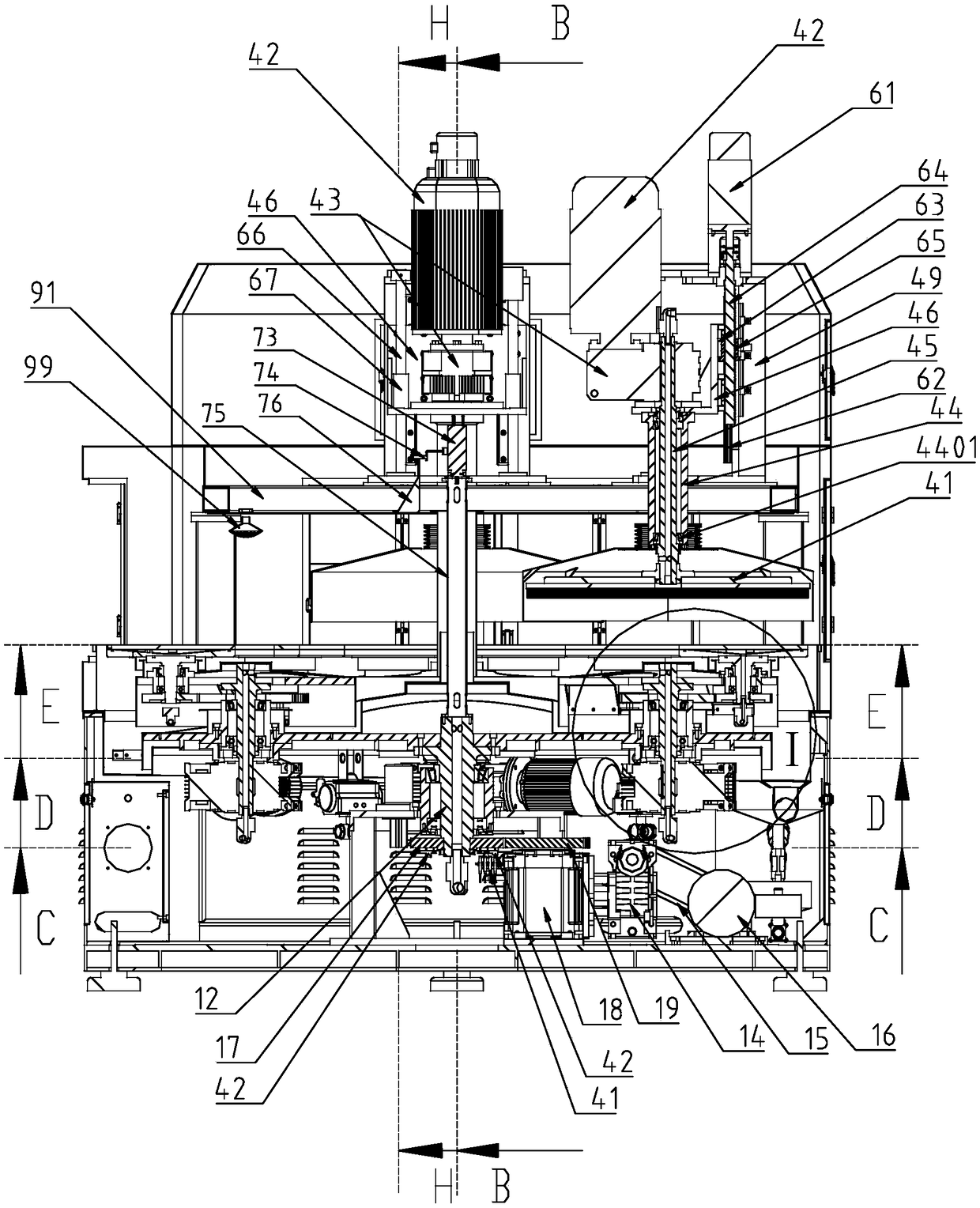

[0028] The structure of the polishing machine of the embodiment of the present invention is as Figure 1 to Figure 12 As shown, the structure of the grinding machine is the same as that of the polishing machine, and the polishing machine includes a frame, an upper plate structure, a lower plate structure and a control circuit.

[0029] The upper plate structure includes three upper plate assemblies 40, each upper plate assembly 40 corresponds to a working station, and there is another loading and unloading inspection station, and the four stations are arranged diagonally across. At the loading and unloading inspection station, there is a shower head 99 for cleaning the workpiece, and the shower head 99 is installed under the beam frame 91 on the frame 10 top.

[0030] The upper plate assembly 40 includes an upper plate 41 , an upper plate elevating mechanism, an upper plate drive mechanism and an upper plate support 49 , and the upper plate support 49 is fixed on the beam fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com