A kind of commercial soybean milk machine pulping method

A soybean milk machine and pulping technology, which is applied in applications, kitchen utensils, household utensils, etc., can solve the problems of poor taste of slurry, blockage of pipelines for transporting slurry, and reduction of crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

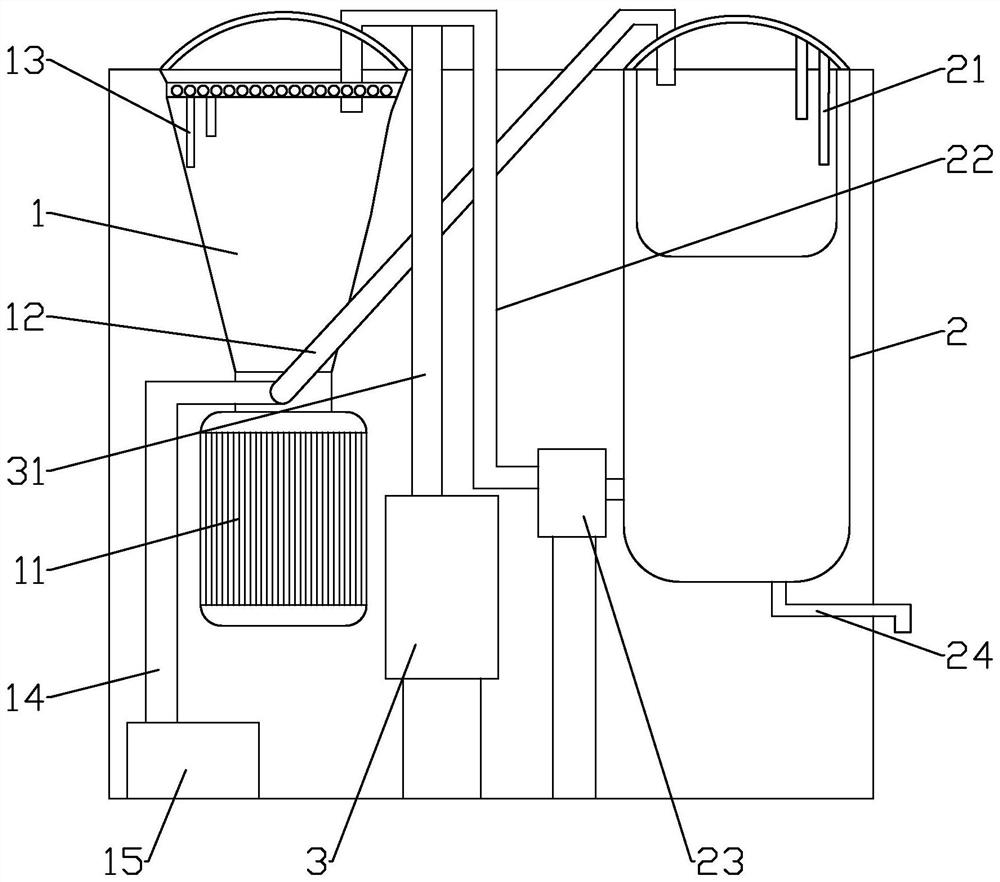

[0025] The present invention provides a pulping method for a commercial soybean milk machine. The commercial soybean milk machine has a pulping tank 1 and a cooking tank 2, see figure 1 , be provided with pulverizing grinding head in pulping bucket 1, pulverizing grinding head is driven by pulping motor 11, comprises the following steps:

[0026] S1, put the material into the pulping barrel 1 and enter into S2;

[0027] S2, add water to the pulping barrel 1 to the first predetermined water level, soak the material for a period of time, and enter S3;

[0028] S3, the pulping motor 11 works to drive the crushing grinding head to rotate forward to crush the material, and at the same time discharge pulp to the cooking tank 2 for a duration of t1, then the pulping motor 11 suspends work and enters S4;

[0029] S4, add water to the pulping barrel 1 to the first predetermined water level, and record the time of adding water, and enter S5;

[0030] S5, repeat S3 and S4 in turn, unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com