Manufacturing mold of movable core rib in hollow floor slab and application thereof

A technology of hollow floor and movable core, which is applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of difficult operation and achieve the effect of reducing the difficulty of operation and convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

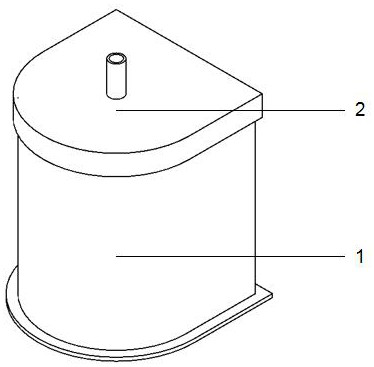

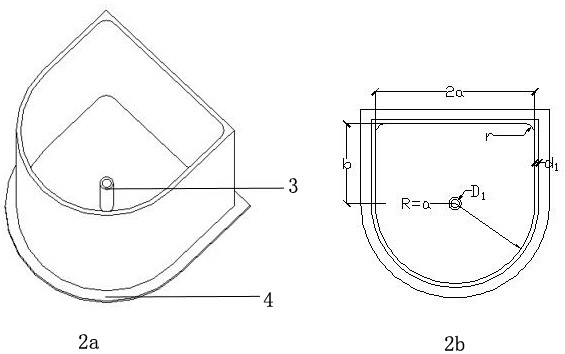

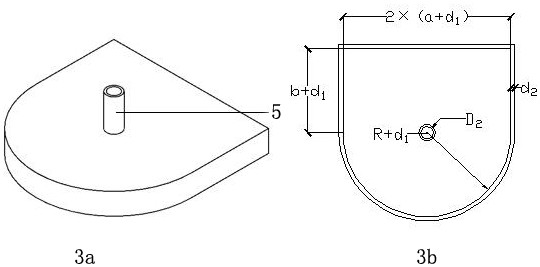

[0043] Attached below Figure 1-7 The present invention is further described in detail: a mold for making movable core ribs in hollow floor slabs, including a mold box body 1 and a mold cover 2, the inner diameter of the mold cover 2 is slightly larger than the outer diameter of the top opening of the mold box body 1, and is used to The top of the mold box body 1 is sealed, and the inner cavity formed by the two is used to form the concrete movable core rib 6; as figure 2 As shown, the top of the mold box 1 is open as the concrete entrance, and a hole I is opened at the bottom, and a pipe I3 is arranged along the axial direction of the hole I. Extend, its height is less than the height of movable core rib 6, thereby forms movable core rib bottom groove 6-1; As image 3 As shown, the mold cover 2 is adapted to the mold box body 1, and there is a hole II on it, which is used as the entrance of the steel bar 6-2 inserted into the mold box body 1, and a pipeline II5 is arrange...

Embodiment 2

[0066] A mold for making movable core ribs in hollow floor slabs, including a mold box body and a mold cover. The inner diameter of the mold cover is slightly larger than the outer diameter of the top opening of the mold box body, and is used to seal the top of the mold box body. The inner diameter formed by the two The cavity is used to form the concrete movable core rib; the top opening of the mold box is used as the concrete entrance, and the bottom is provided with columnar protrusions along its height direction. Groove; the mold cover is adapted to the mold box body, and there is a hole II on it, which is used as the entrance for the steel bar to be inserted into the mold box body.

[0067] As a preferred solution of this embodiment, a pipeline II is provided along the axial direction of the hole II, and the height direction of the pipeline II extends away from the mold box body. When the concrete is poured into the mold, it plays the role of inserting and fixing the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com