A cable three-coordinate axis positioning tool

A technology of coordinate positioning and axis positioning, used in manufacturing tools, circuits, electrical components, etc., can solve the problems of difficult errors, poor cable quality, poor consistency, etc., to reduce assembly difficulty, good assembly consistency, and avoid short-circuit phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

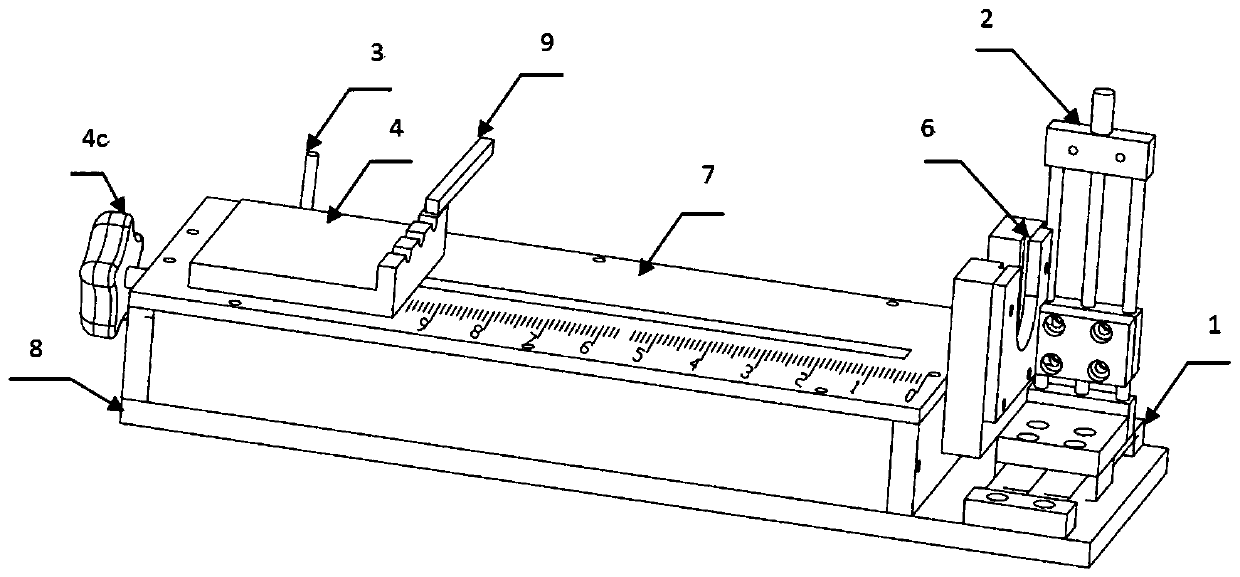

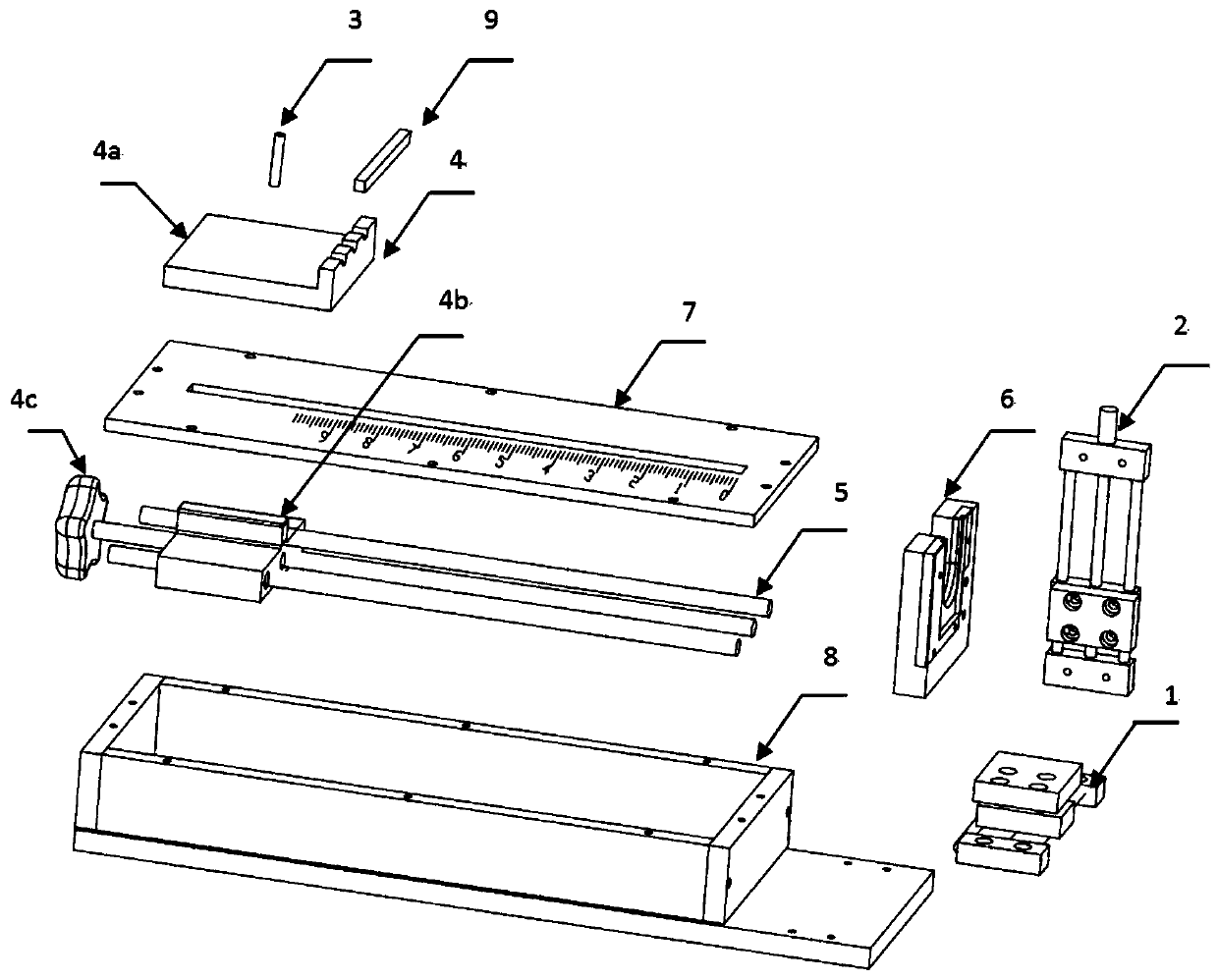

[0026] A cable three-coordinate axis positioning tool, the tool includes an X-axis coordinate positioning guide rail 1 and a Y-axis coordinate positioning guide rail 2, a positioning rod 3, a mobile positioning module 4, a positioning module 4a, a moving module 4b, adjustable knobs 4c, Z Axis coordinate positioning guide rail 5, U-shaped installation module 6, Z-axis coordinate plane 7, base 8, pressure plate 9;

[0027] Slider 2 can position guide rail 1 along the X-axis coordinates and move along the guide rail, that is, move along the X-axis;

[0028] The slider one can move along the guide rail 2 on the Y-axis coordinate positioning guide rail, that is, move along the Y-axis;

[0029] The Z-axis coordinate positioning guide rail 5 is installed on the base 8, and the mobile positioning module 4 can move along the guide rail on the Z-axis coordinate positioning guide rail 5, that is, move along the Z-axis;

[0030] The U-shaped installation module 6 is installed on one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com