Double-nozzle extrusion type ceramic 3D printer and printing method thereof

A 3D printer, extrusion-type technology, applied in the direction of ceramic molding machines, manufacturing tools, additive processing, etc., can solve the printing accuracy constraints extrusion-type ceramic 3D printing technology popularization and promotion, printing efficiency constraints extrusion-type ceramic 3D printing Technical production application, long printing time and other problems, to achieve the effect of simple structure, short printing time and high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the present invention will be further described:

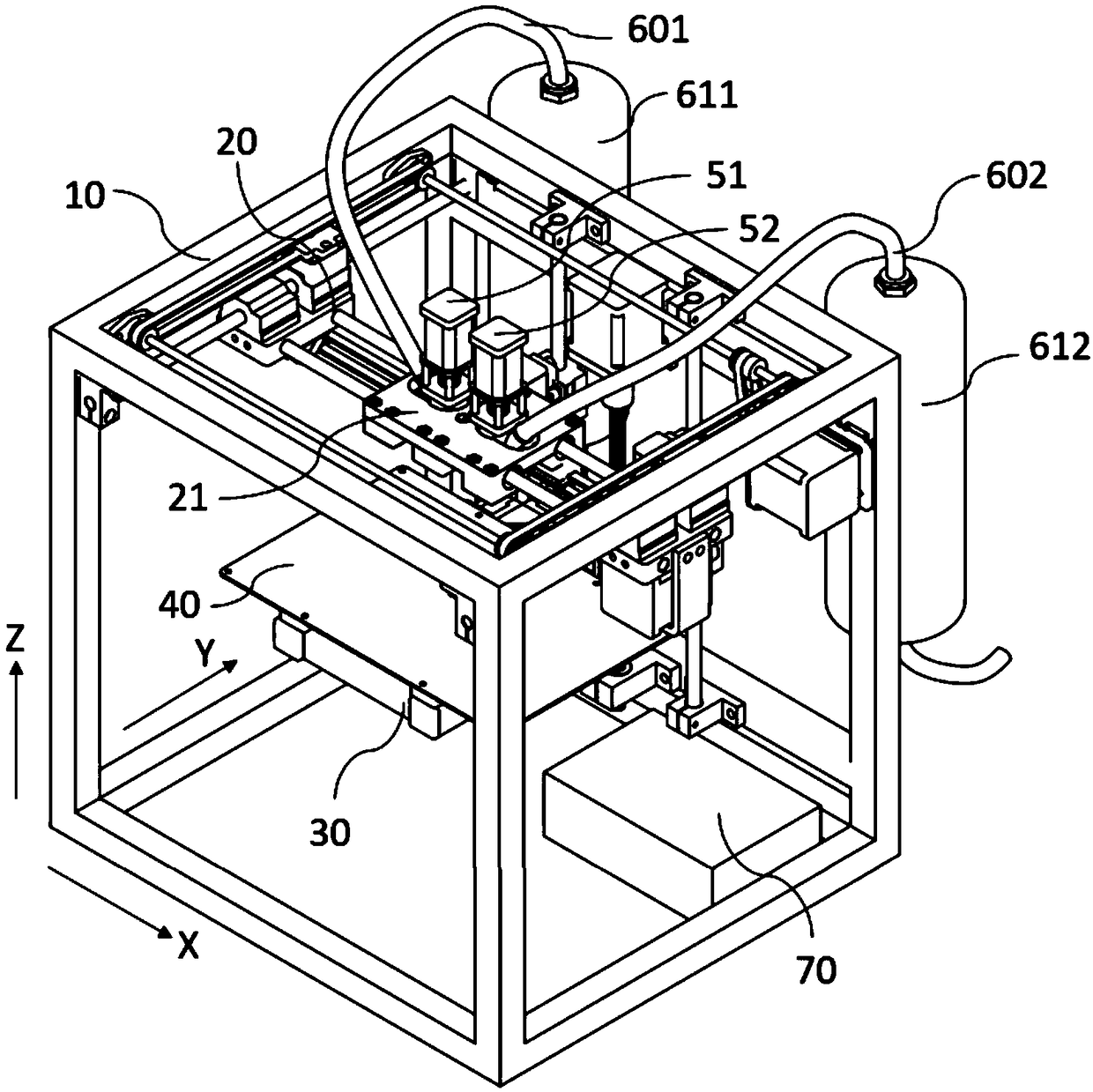

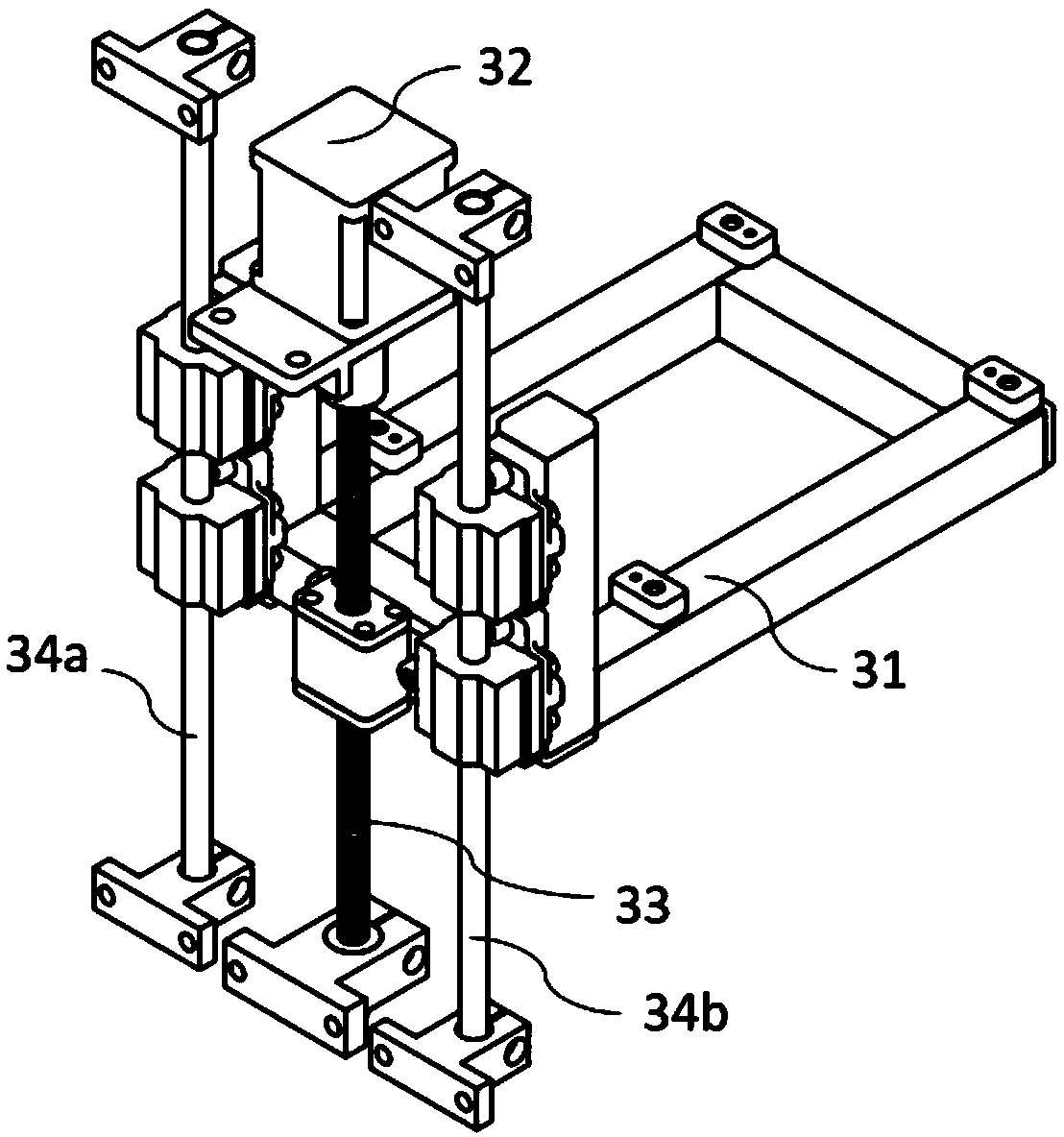

[0045] Such as figure 1 , the dual-nozzle extruded ceramic 3D printer of the present invention includes a frame 10 , an XY plane movement module 20 , a Z-axis movement module 30 , a loading plate 40 , a printing nozzle, a feeding module, an air compressor and a master control module 70 .

[0046] Wherein, the printing nozzle includes a fine printing nozzle 51 and a coarse printing nozzle 52 ; the feeding module includes a first feeding pipe 601 , a second feeding pipe 602 , a first storage tank 611 and a second storage tank 612 .

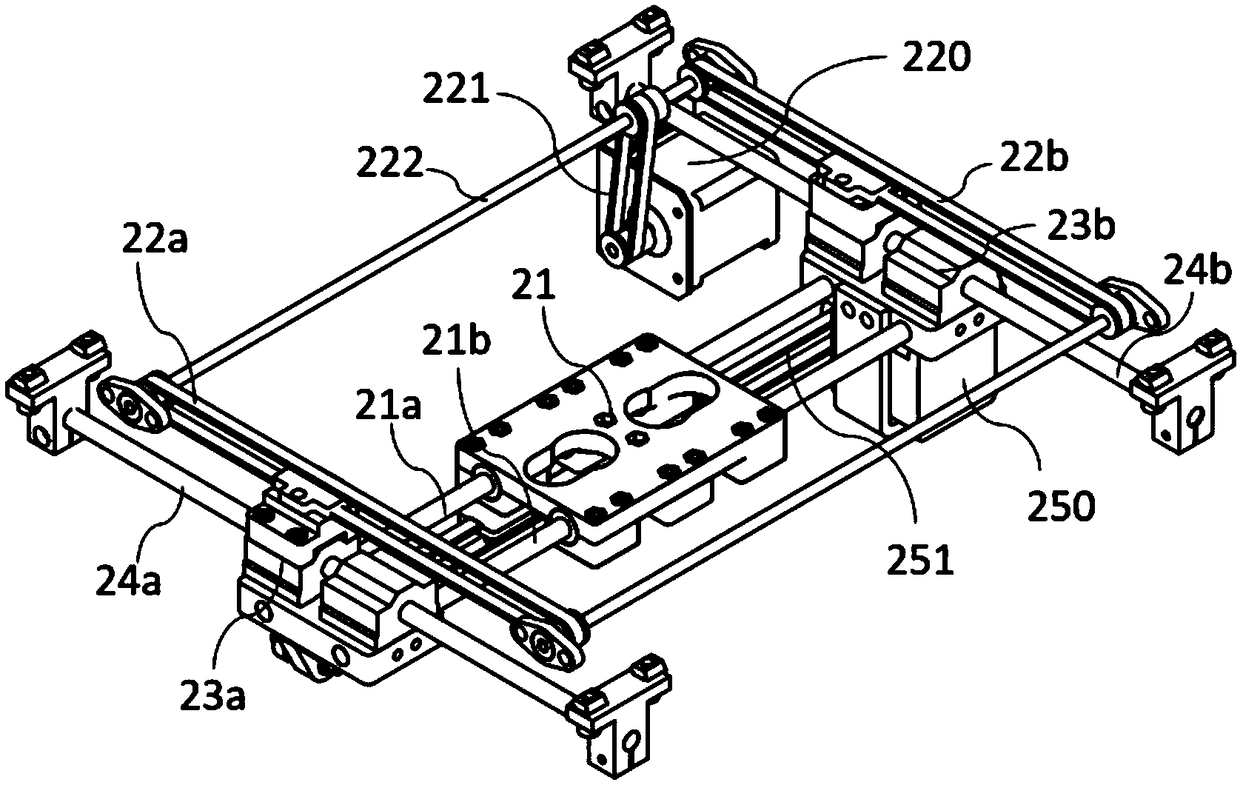

[0047] The XY surface motion module 20 is installed above the frame 10, the nozzle mounting plate 21 of the XY surface motion module 20 can realize the two-dimensional movement of the XY plane, and the fine printing nozzle 51 and the coarse printing nozzle 52 are fixedly connected to the nozzle mounting plate 21 , are respectively connected to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap