Automatic concrete proportioning device

An automatic proportioning and concrete technology, which is applied to clay preparation devices, mixing operation control devices, and sales of raw material supply devices, etc., can solve problems such as low efficiency, waste of materials, and high labor intensity, and achieve accurate ingredients, convenient cleaning, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

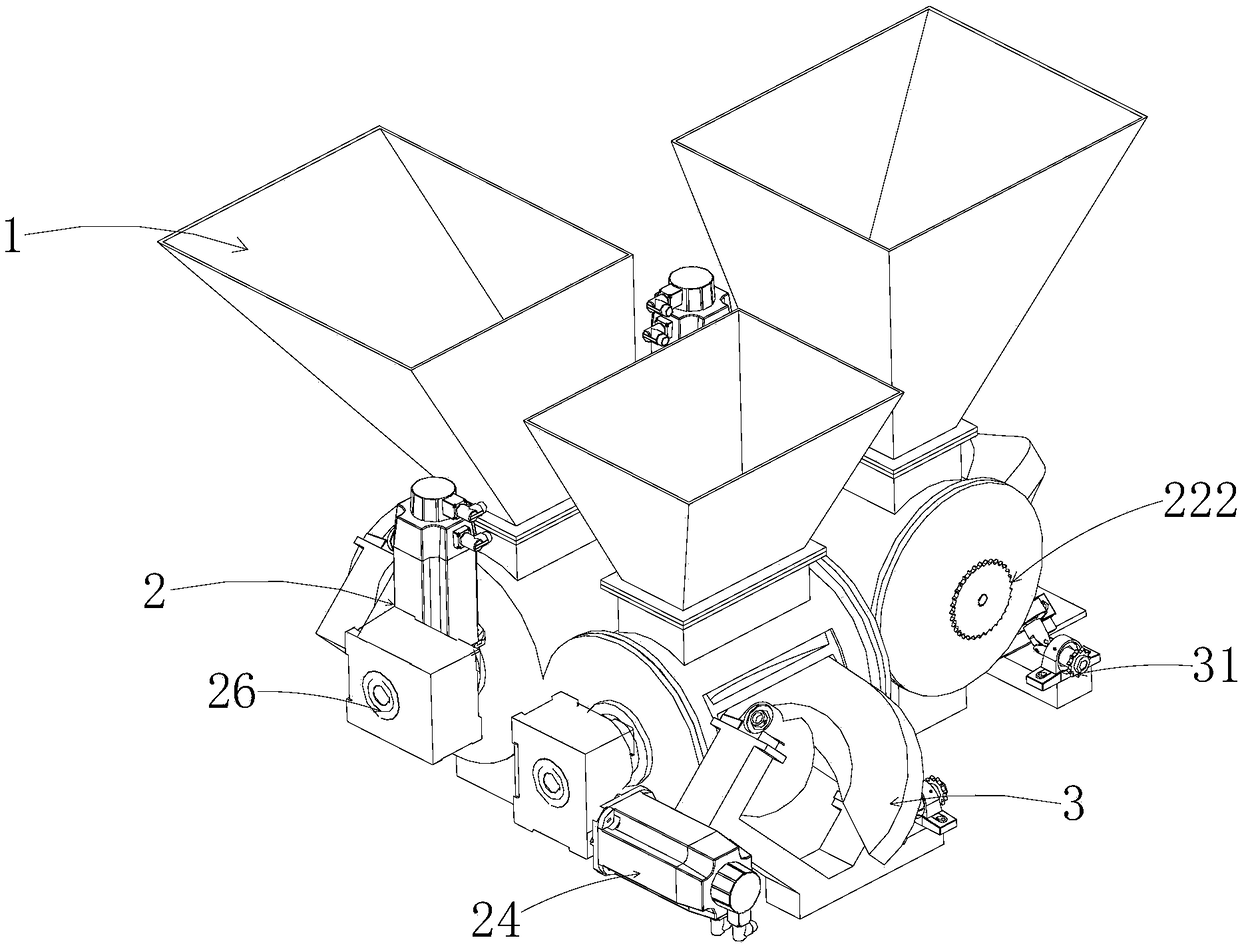

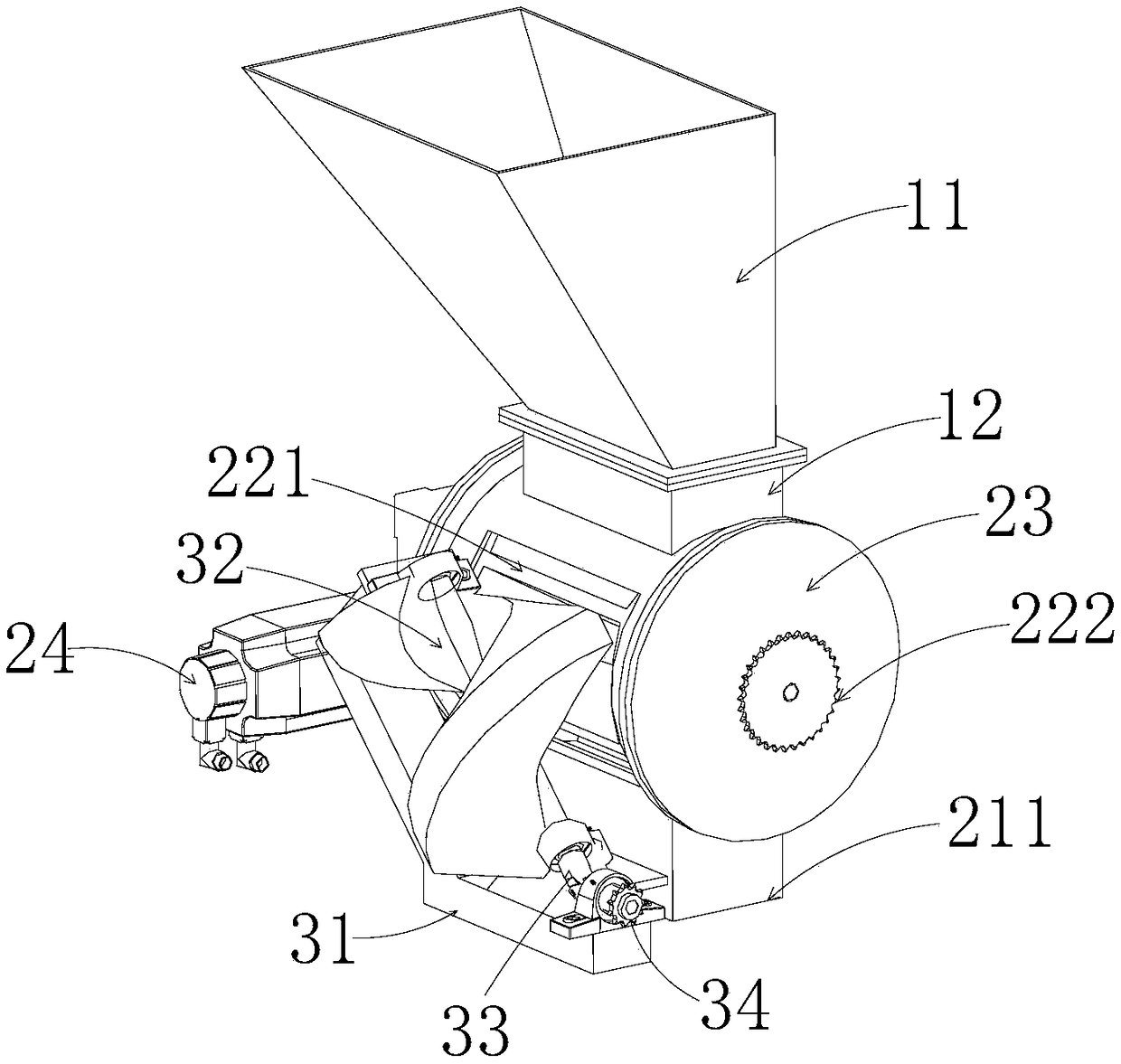

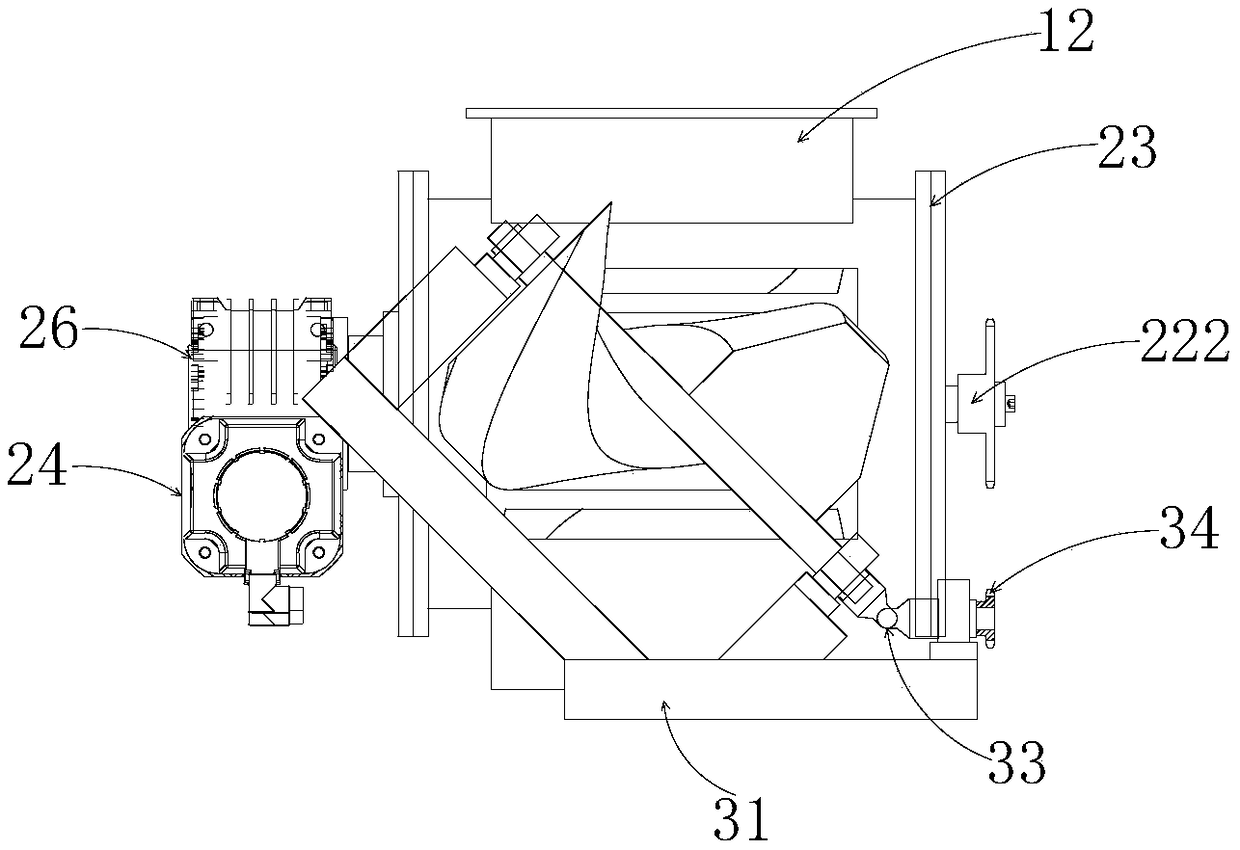

[0025] combine Figure 1 to Figure 6 As shown, the specific implementation of a concrete automatic proportioning device provided by the present invention is as follows.

[0026] The concrete automatic proportioning device is specifically a proportioning device composed of more than two proportioning mechanisms, and a proportioning device composed of three proportioning mechanisms is commonly used. More than 2 proportioning mechanisms are used to realize the simultaneous proportioning of more than 2 kinds of concrete raw materials, and the volumetric proportioning method is adopted. The equipment has a compact structure and a small volume, and is suitable for underground environments with narrow spaces. Each proportioning mechanism includes a hopper 1 , a cleaning component 3 and a discharge component 2 , the discharge component 2 is fixedly installed under the hopper 1 , and the cleaning component 3 is arranged on the side of the discharge component 2 . The material enters fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com