Pulling type luggage feeding and discharging mechanism

A technology of pull-out and luggage, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of improper size of luggage, chaotic luggage transmission, deformation of suitcases, etc., to achieve smooth transportation, convenient maintenance and Repair, reduce the effect of blocking and bumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

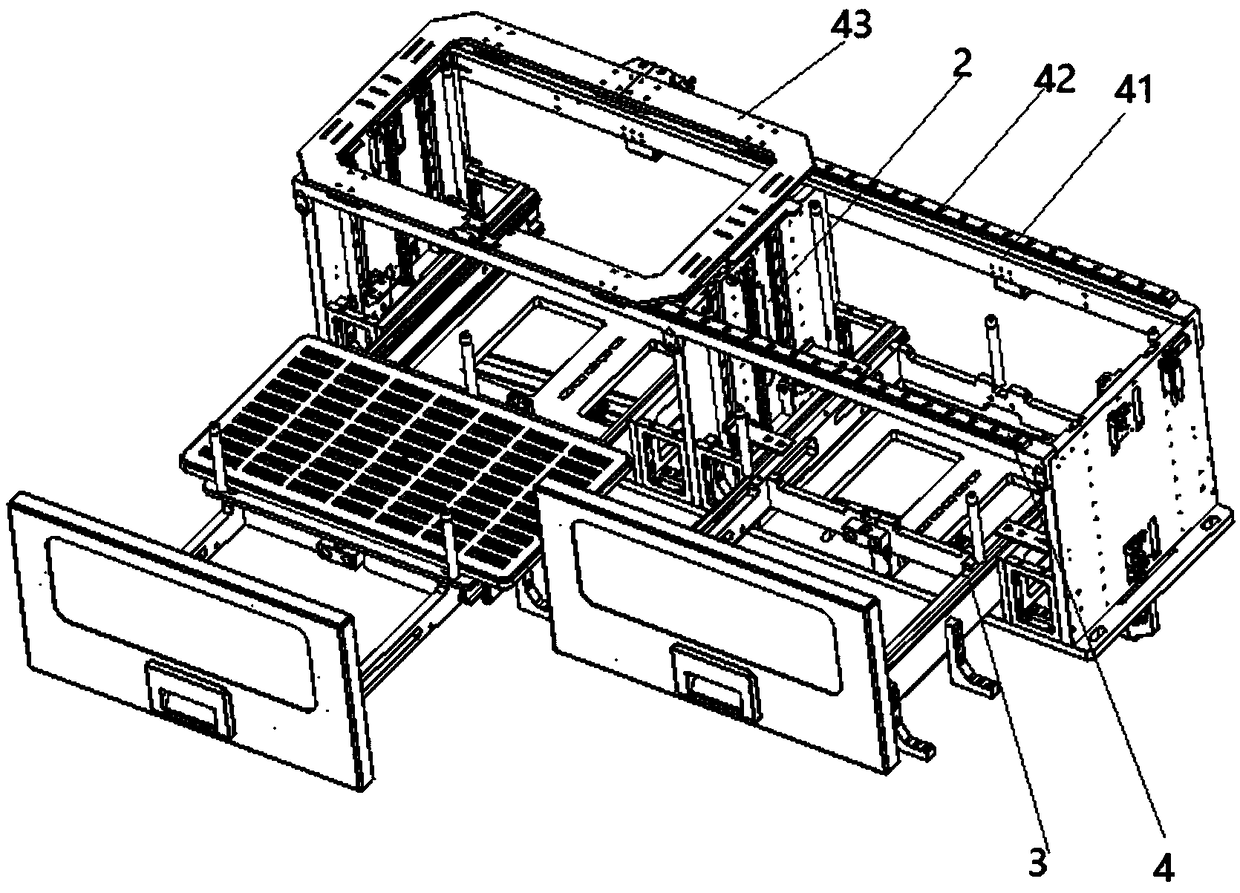

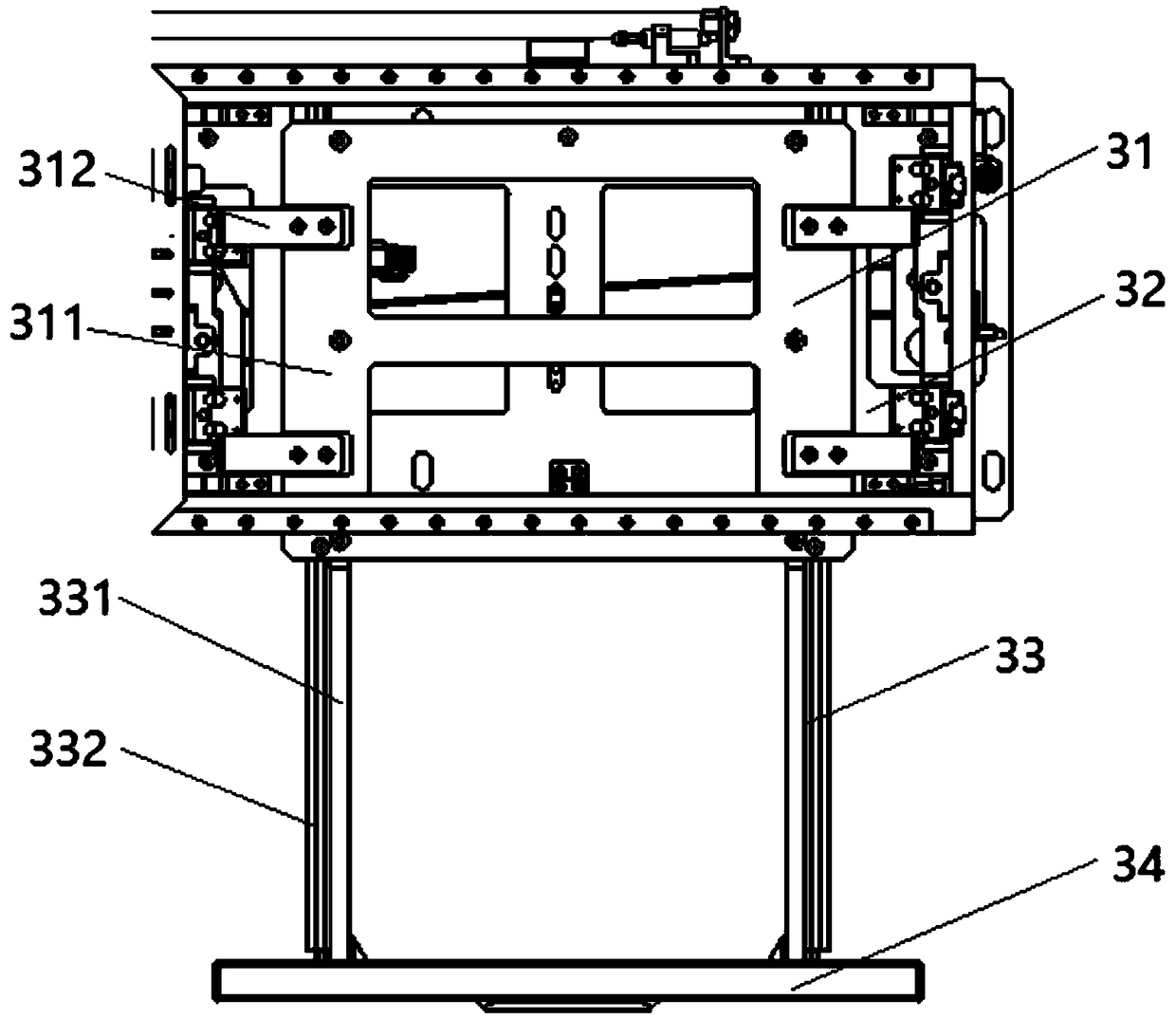

[0022] see Figure 1 to Figure 5 , a pull-type loading and unloading mechanism for luggage according to the present invention, a packaging base 1, a lifting mechanism 2 and a loading and unloading pulling mechanism 3 are arranged above the base 1, and several lifting mechanisms 2 are arranged on the base in parallel and symmetrically. 1, the lifting mechanism 2 is vertically arranged on the base 1, and the upper end of the lifting mechanism 2 is provided with a transport track 4, and the transport track 4 is erected on the upper end of the lifting mechanism 2, and a set of loading and unloading pumps is arranged between the two sets of lifting mechanisms 2. Pull mechanism3.

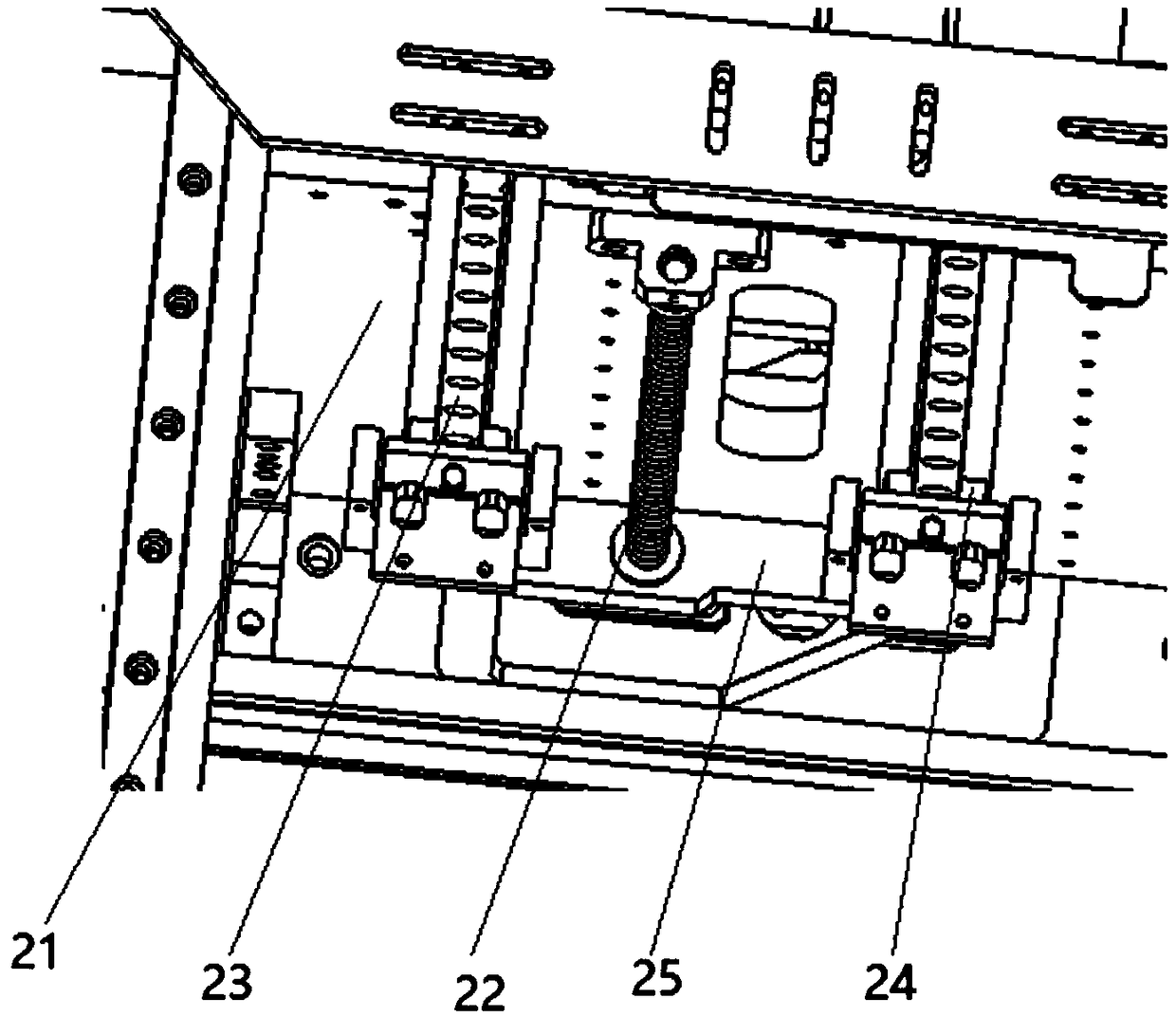

[0023] The lifting mechanism 2 includes a base plate 21, a leading scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com