Wide temperature range negative thermal expansion Laves phase alloy and preparation method thereof

A technology with negative thermal expansion and wide temperature range, applied in the field of negative thermal expansion Laves phase alloy materials, can solve the problems of narrow temperature window and impossibility of practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

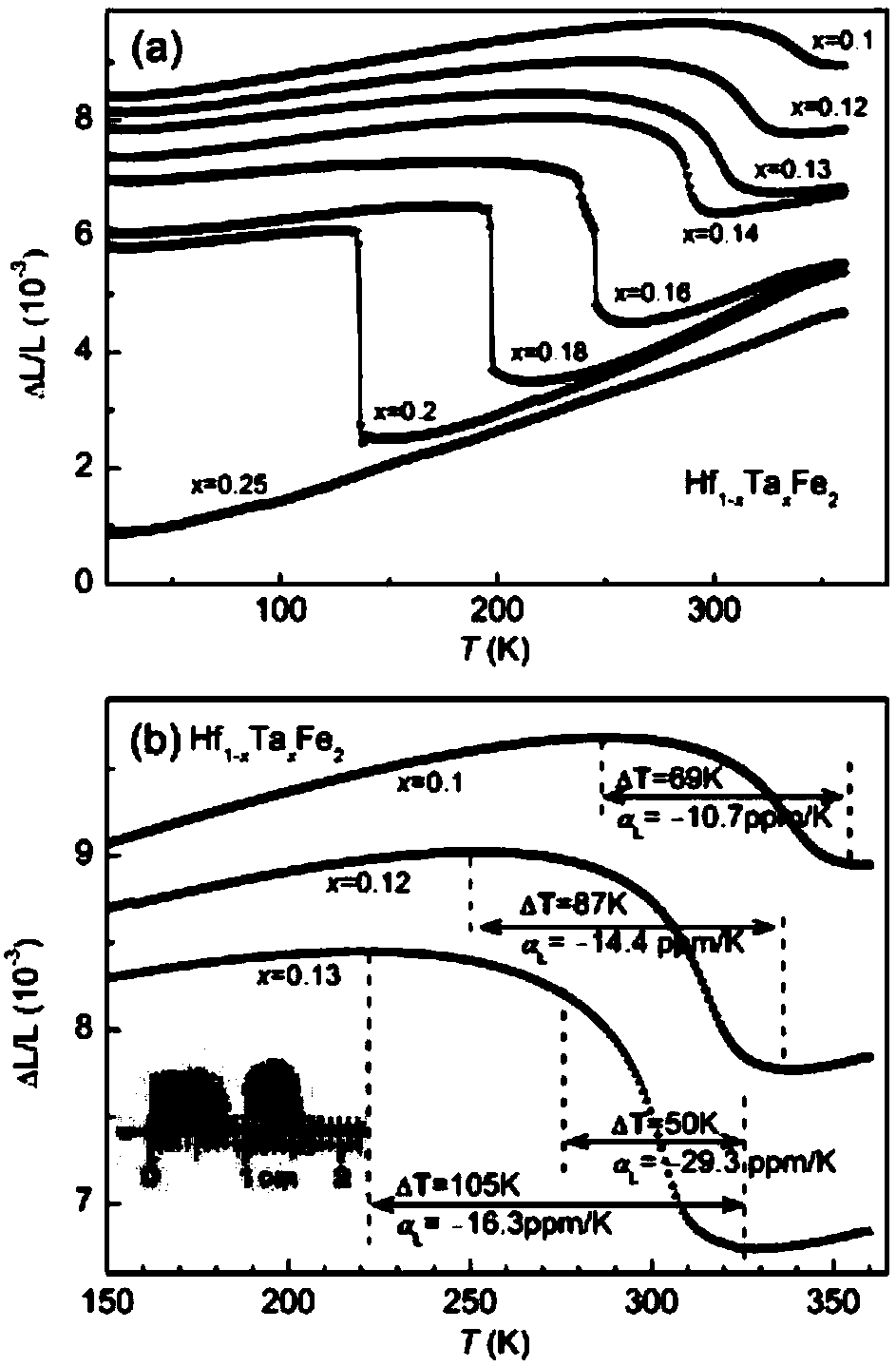

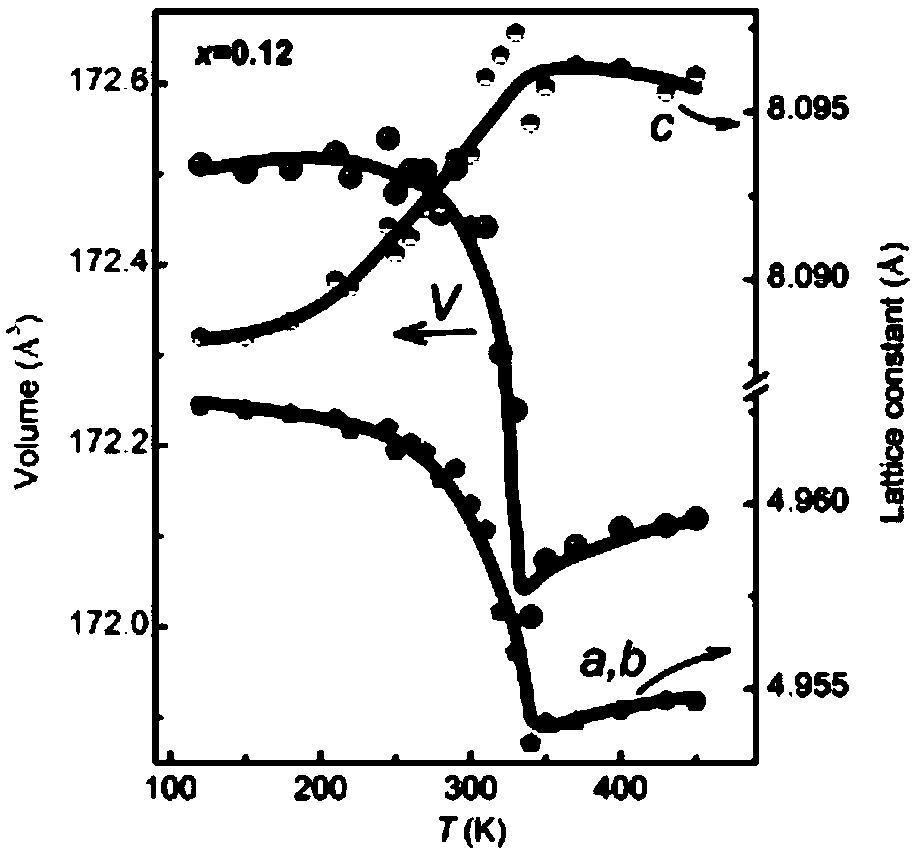

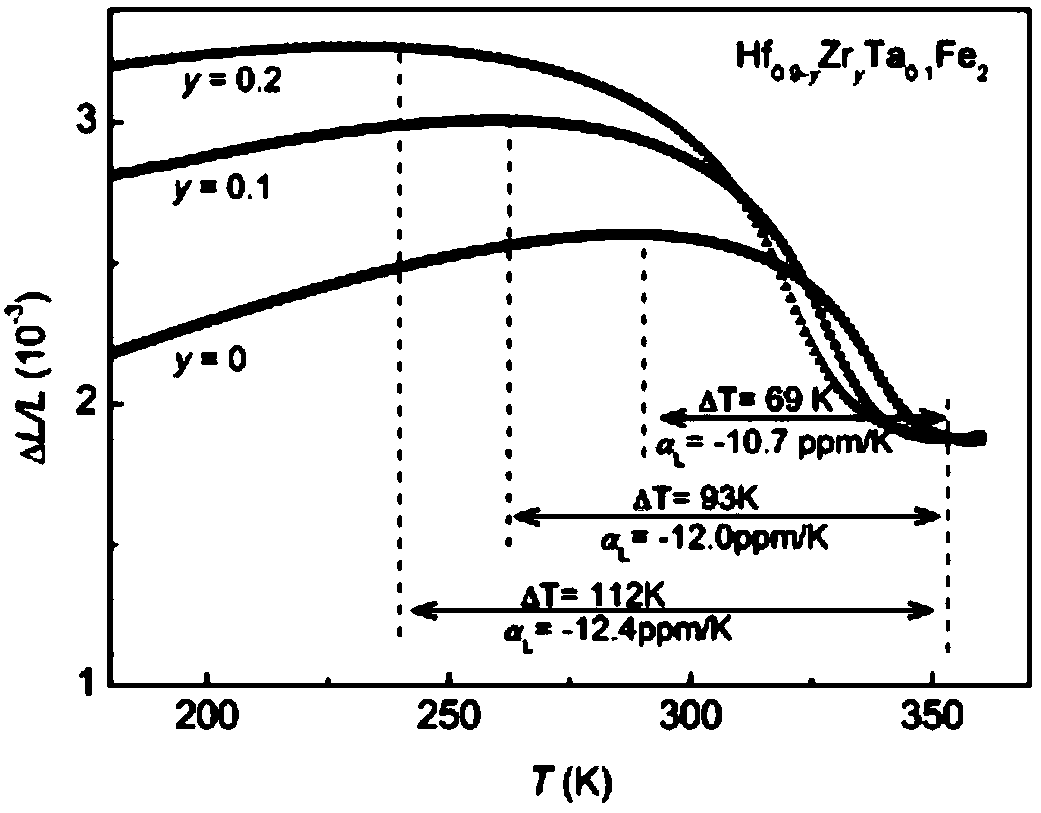

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to the stoichiometric ratio, 11.17g iron block, 16.06g Hf rod (purity is 99.9%), and 1.81g Ta sheet are placed in a copper crucible, and arc melting is carried out 6 times under an argon atmosphere. After each arc melting is completed, the ingot is cast Stir once, then anneal under vacuum conditions, the annealing temperature is 1100°C, and the annealing time is 7 days, to obtain a wide temperature range negative thermal expansion Laves phase alloy Hf 0.9 Ta 0.1 Fe 2 .

Embodiment 2

[0029] According to the stoichiometric ratio, 11.17g iron block, 15.88g Hf rod (purity is 99.9%), and 1.99g Ta sheet are placed in a copper crucible, and arc melting is carried out 8 times under an argon atmosphere. The ingot was turned once, and then annealed under vacuum conditions, the annealing temperature was 900°C, and the annealing time was 7 days to obtain a wide temperature range negative thermal expansion Laves phase alloy Hf 0.89 Ta 0.11 Fe 2 .

Embodiment 3

[0031] Take by weighing 11.17g iron nugget, 15.71g Hf rod (purity is 99.9%), 2.17g Ta sheet according to stoichiometric ratio and place in copper crucible, carry out electric arc melting 7 times under argon atmosphere, after each electric arc melting is finished, put Turn the ingot once, then place the arc-melted ingot in a quartz tube, evacuate the quartz tube and seal it, place the sealed quartz tube in a box-type resistance furnace for annealing, the annealing temperature is 900°C, and the annealing time is In 7 days, the Laves phase alloy Hf with negative thermal expansion in wide temperature range was obtained 0.88 Ta 0.12 Fe 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com