A municipal bridge cleaning and maintenance device

A technology of maintenance device and cleaning device, applied in cleaning methods, road cleaning, construction, etc., can solve the problems of dangerous operation, increased maintenance cost, corrosion, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

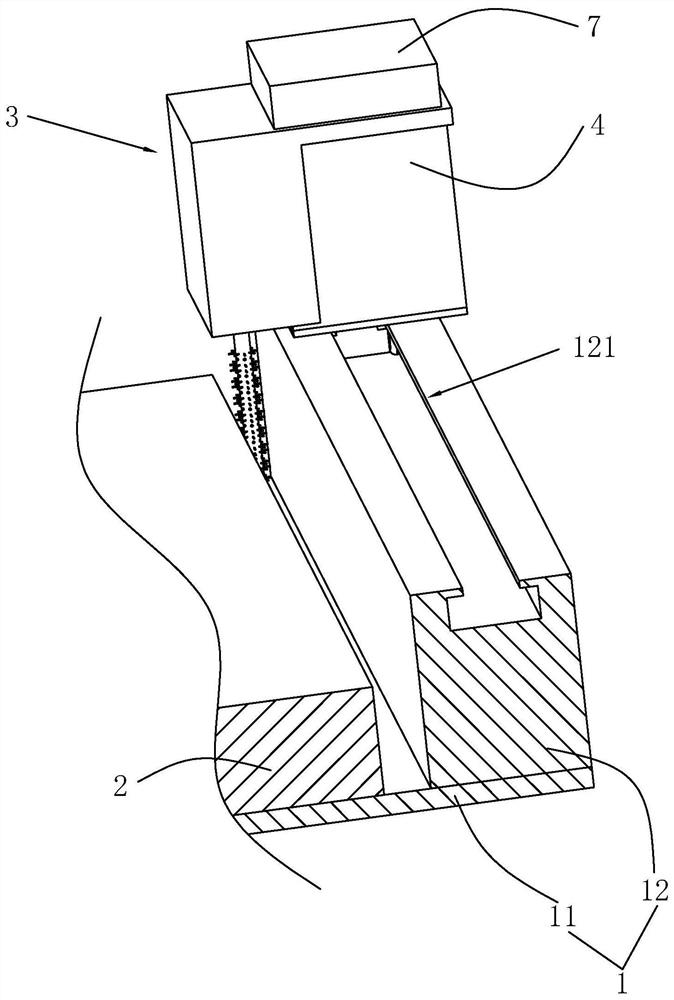

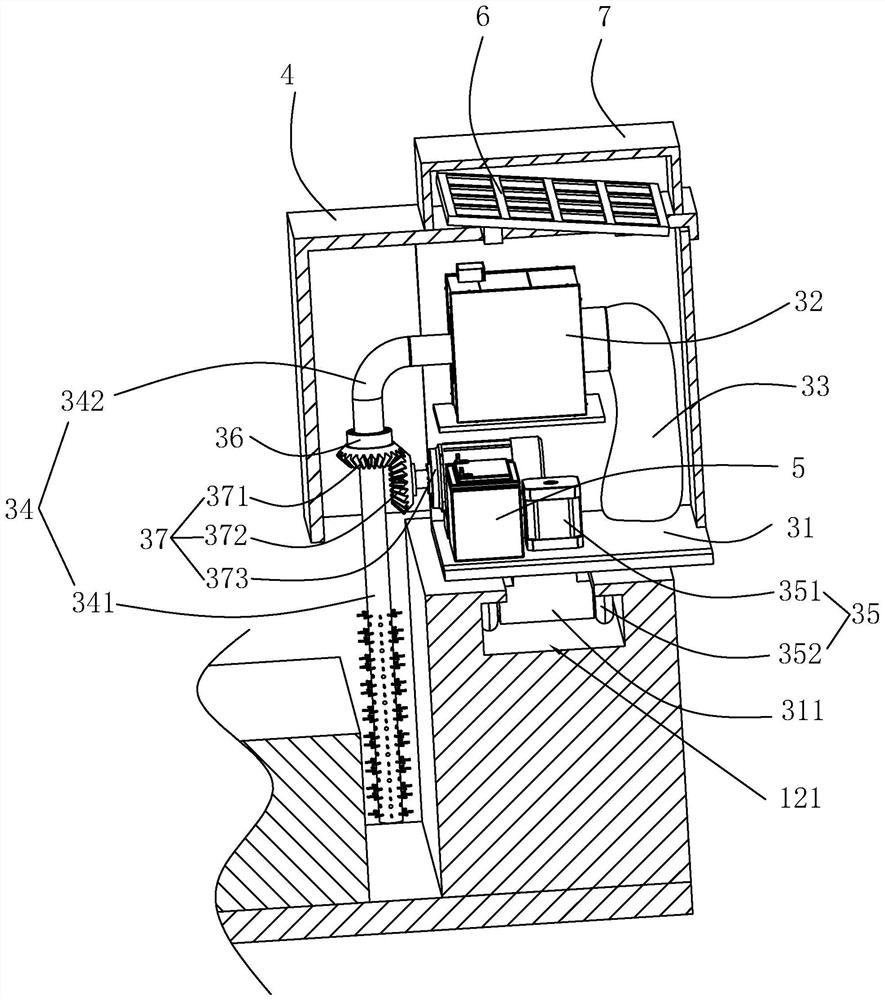

[0035] like figure 1 As shown, a cleaning and maintenance device for municipal bridges is provided with a cleaning device 3 on the limiting section 12 . The cleaning device 3 includes an installation plate 31, an exhaust fan 32, a dust bag 33 and a dust extraction pipe 34. The exhaust fan 32 is arranged on the installation plate 31. One end of 32 for air outlet is communicated with the dust bag 33 . The mounting plate 31 is also provided with a power supply 5 for driving the exhaust fan 32 to work.

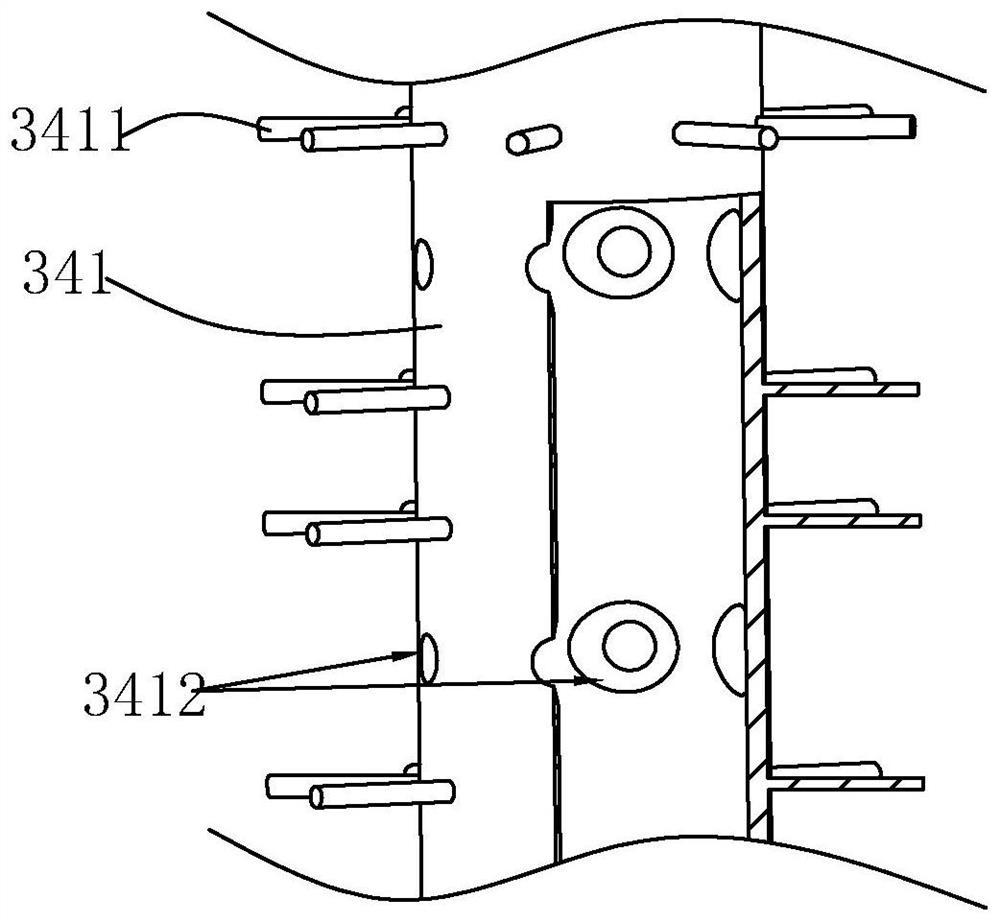

[0036] like figure 1 , 2 As shown, the dust suction pipe 34 includes a working section 341 and a dust suction section 342 , the working section 341 is inserted into the gap, and the dust suction section 342 communicates with the air inlet section of the suction fan 32 . The side wall of the working section 341 is provided with a plurality of through holes 3412 in the shape of a truncated cone, and the larger end faces the inside of the working section 341 (see image 3 ). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com