A lean-burn organization method for a dual-fuel engine

A dual-fuel engine, lean combustion technology, applied to combustion engines, internal combustion piston engines, engine control, etc., can solve the problems of increased HC emissions, low engine economy, and reduced reliability, and achieve the effect of low-emission combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

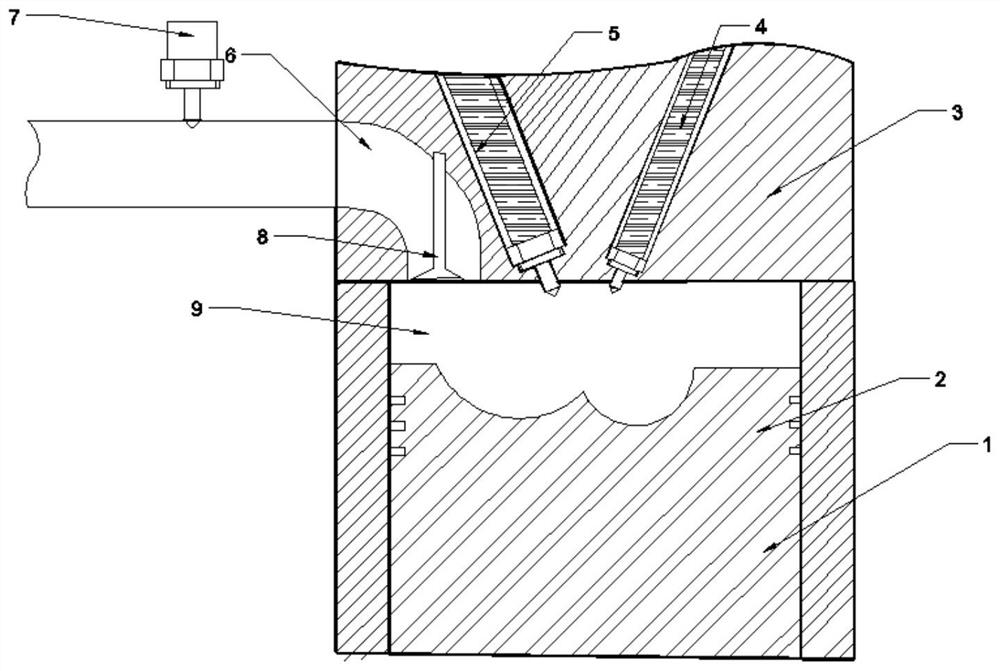

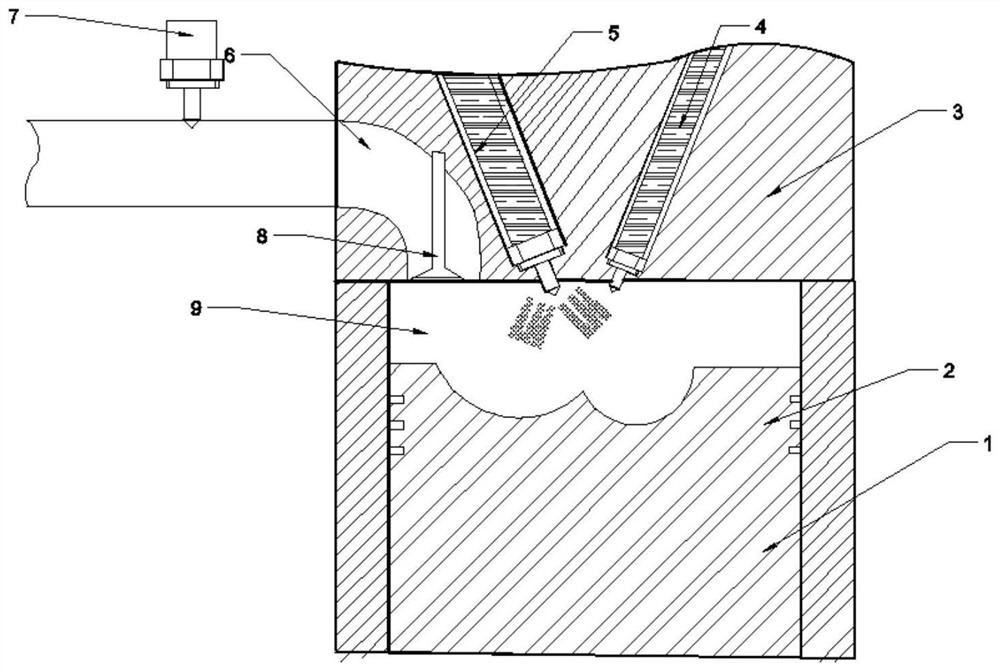

[0030] Such as figure 1 Shown, the dual-fuel engine combustion system that the present invention relates to mainly consists of piston (1), cylinder (2), cylinder head (3), secondary fuel injector (4), main fuel injector (5), spiral inlet (6), low-pressure natural gas injection valve (7), intake valve (8) and combustion chamber (9).

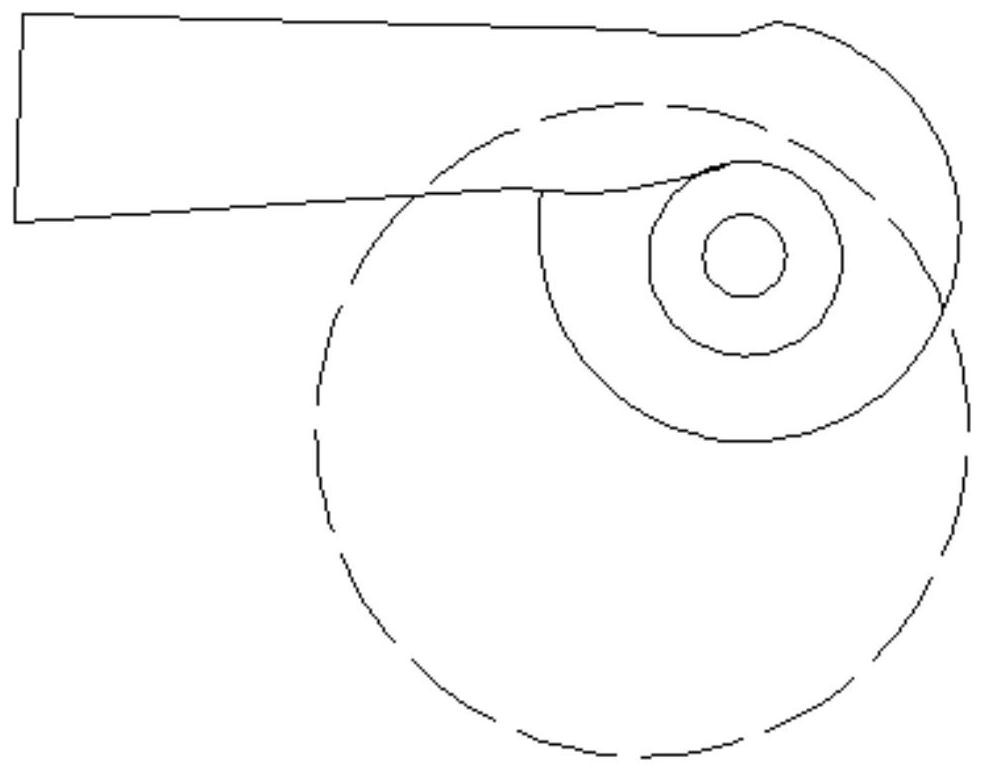

[0031] Such as figure 2 , the helical inlet of the dual-fuel engine combustion system is composed of an air passage inlet, a helical chamber and an air passage outlet, wherein the helical chamber is composed of multiple tangent three-dimensional circular arcs. During the intake stroke, the spiral intake port forces the air into the cylinder along the expected diversion direction, generating a strong vortex, so that the air and gas are fully mixed. The intake port adopts a spiral structure. Under the action of the intake swirl, the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com