Novel efficient spark ignition engine

An engine, ignition technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of high thermal efficiency, unreachable, etc., and achieve the effect of improving thermal efficiency, simple structure, and improving piston cooling function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

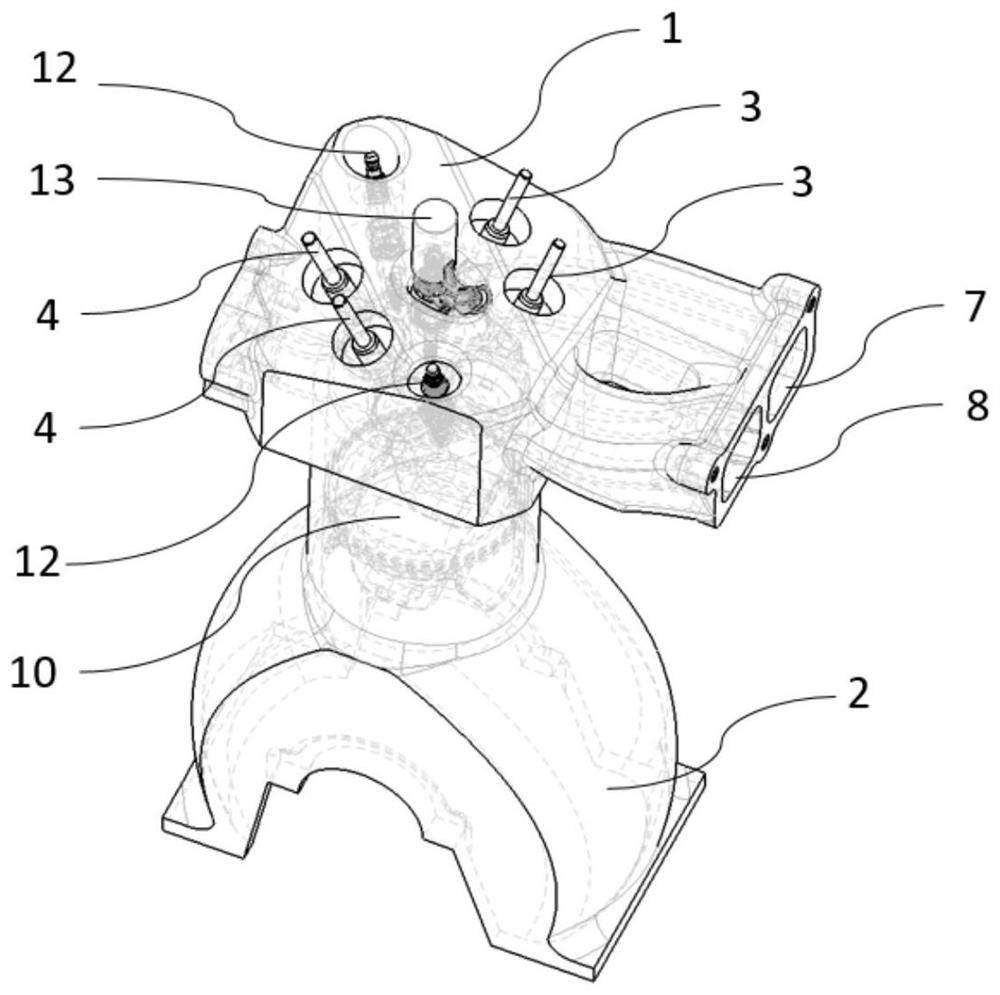

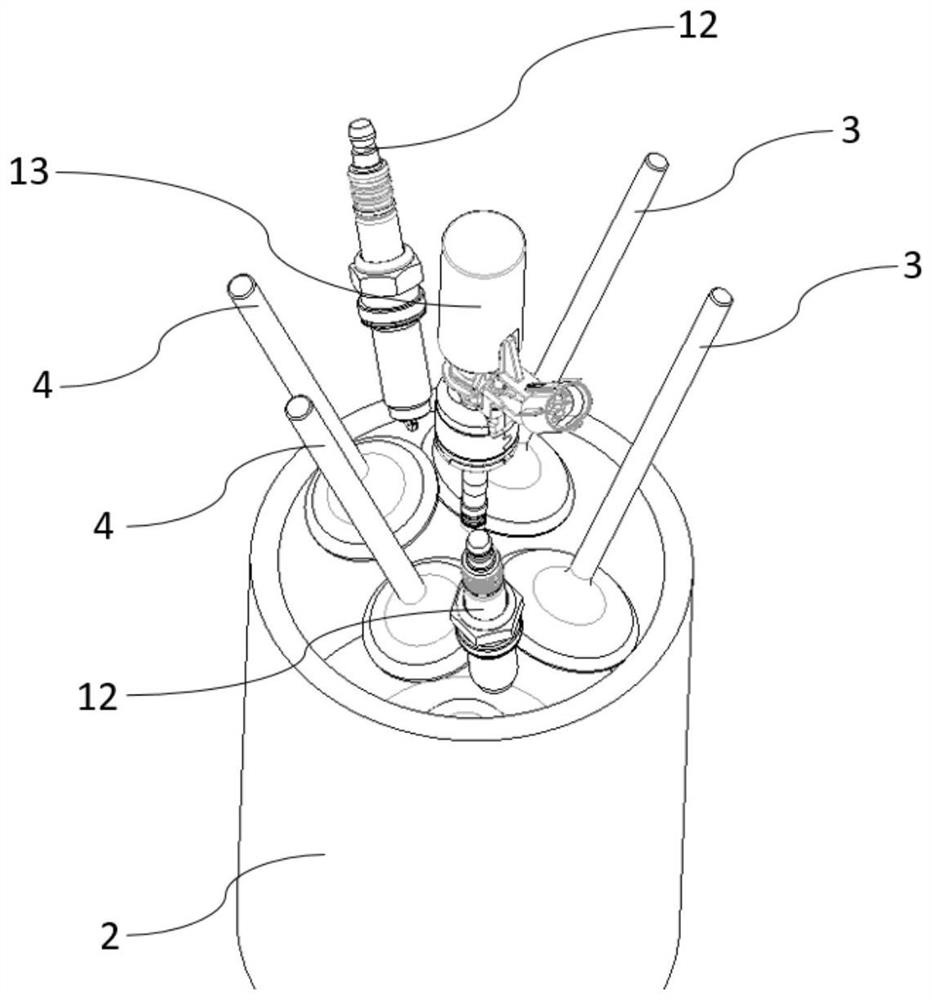

[0033] see Figure 1-7 , the present invention provides a technical solution: a novel high-efficiency ignition engine, comprising:

[0034] Four-valve cylinder head 1, the interior of the four-valve cylinder head 1 is cast and integrated with two vortex intake ports;

[0035] In-cylinder air mixture ignition mechanism composed of double spark plugs 12;

[0036] Combustion chamber composed of cylinder block 2, piston 10, four-valve cylinder head 1, intake valve 3 and exhaust valve 4 components.

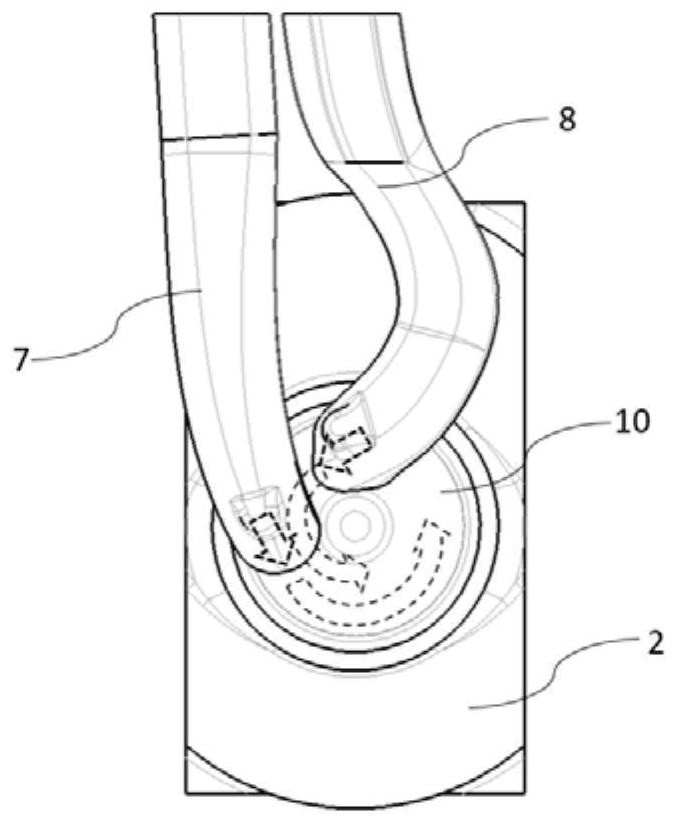

[0037] Further, the two swirl inlets include an outer swirl inlet 7 and an inner swirl inlet 8, and the outer swirl inlet 7 and the inner swirl inlet 8 connect the combustion chamber to the intake manifold. The tubes form the engine intake passages.

[0038] Further, the two vortex inlets are arranged in a separate manner, and the air is respectively taken from the intake manifold, and the two vortex inlets are respectively fed in, thereby avoiding airflow interference.

[0039] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com