Magnetic suspension bearing high in reliability

A magnetic suspension bearing and reliability technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of rotor imbalance, increase the labor force of the staff, reduce the reliability of the device, etc., to improve the reliability performance and facilitate the promotion. , reduce the effect of carton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

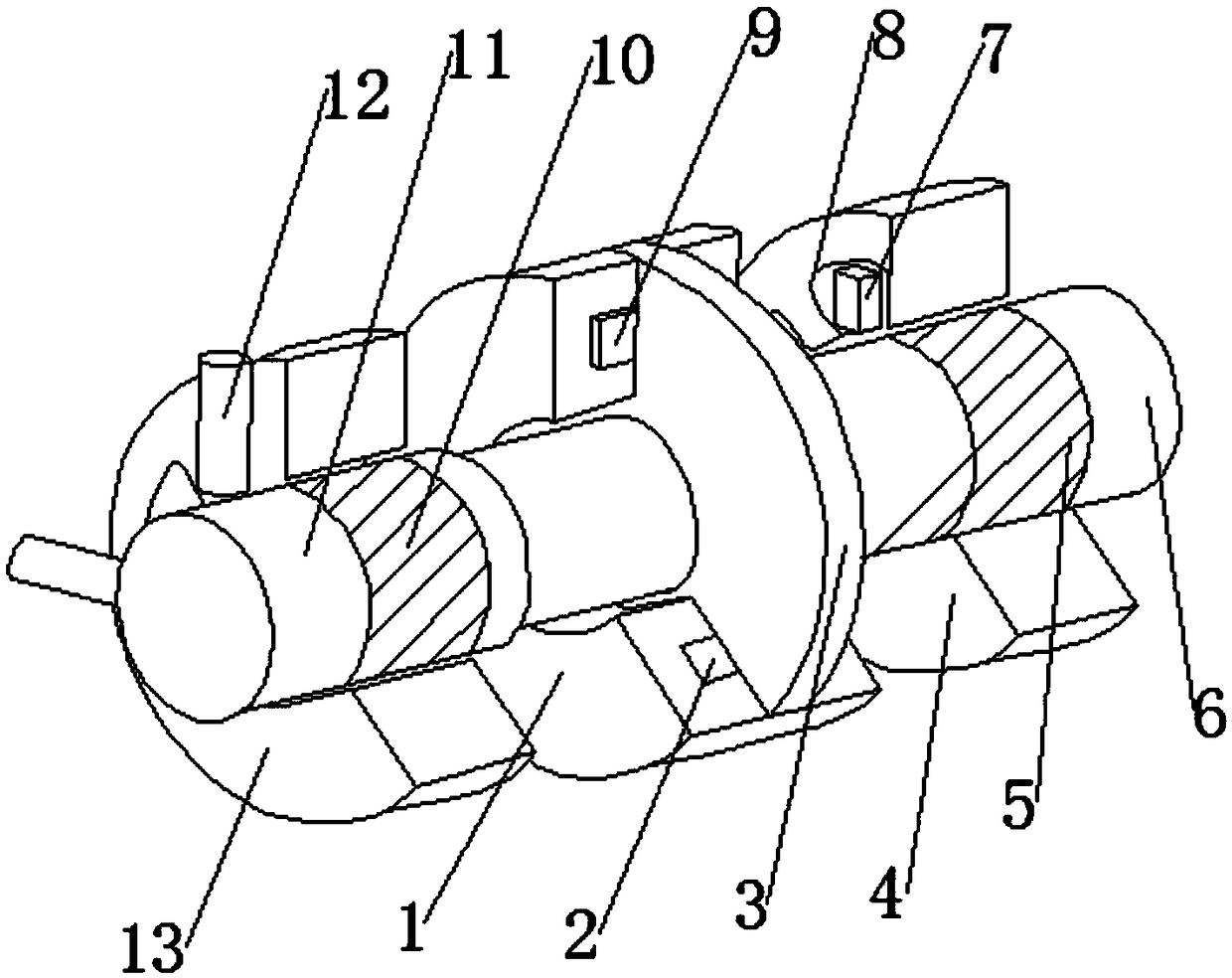

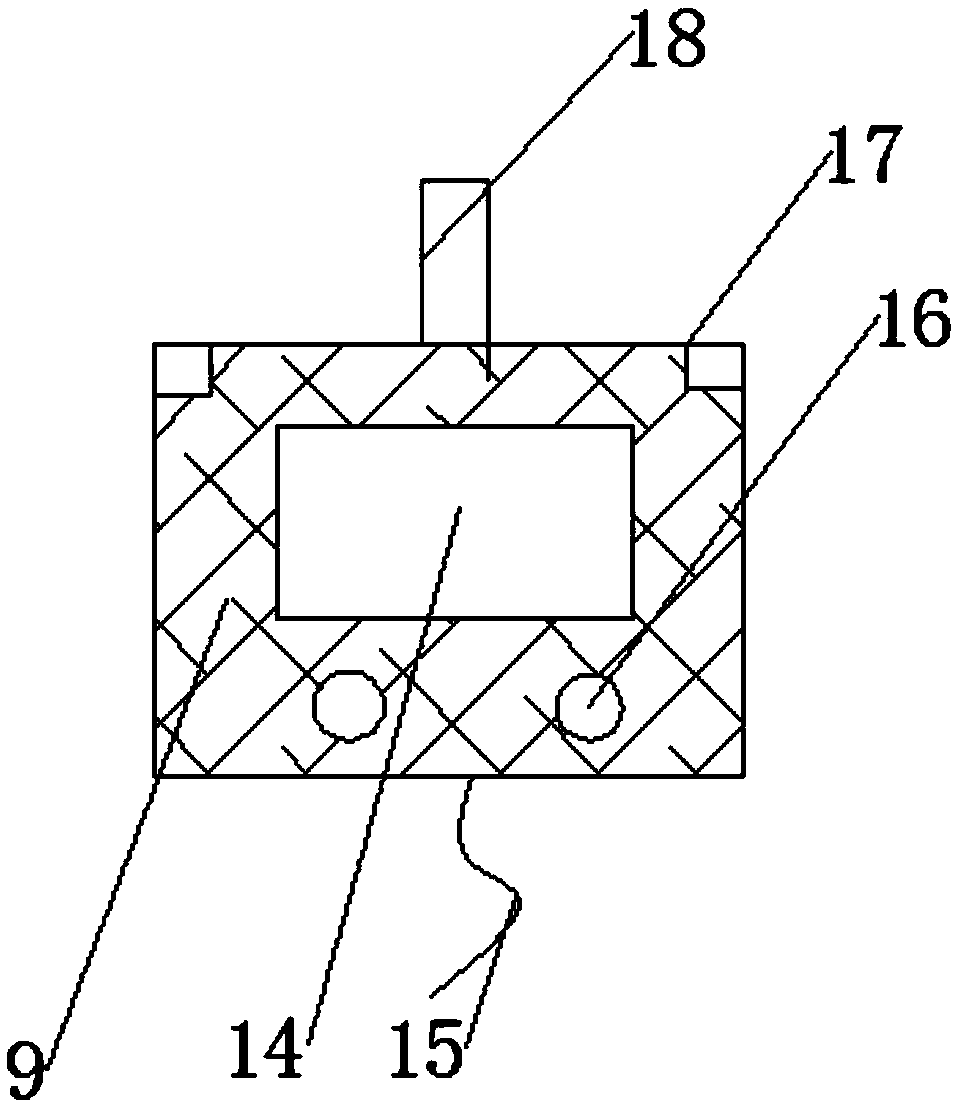

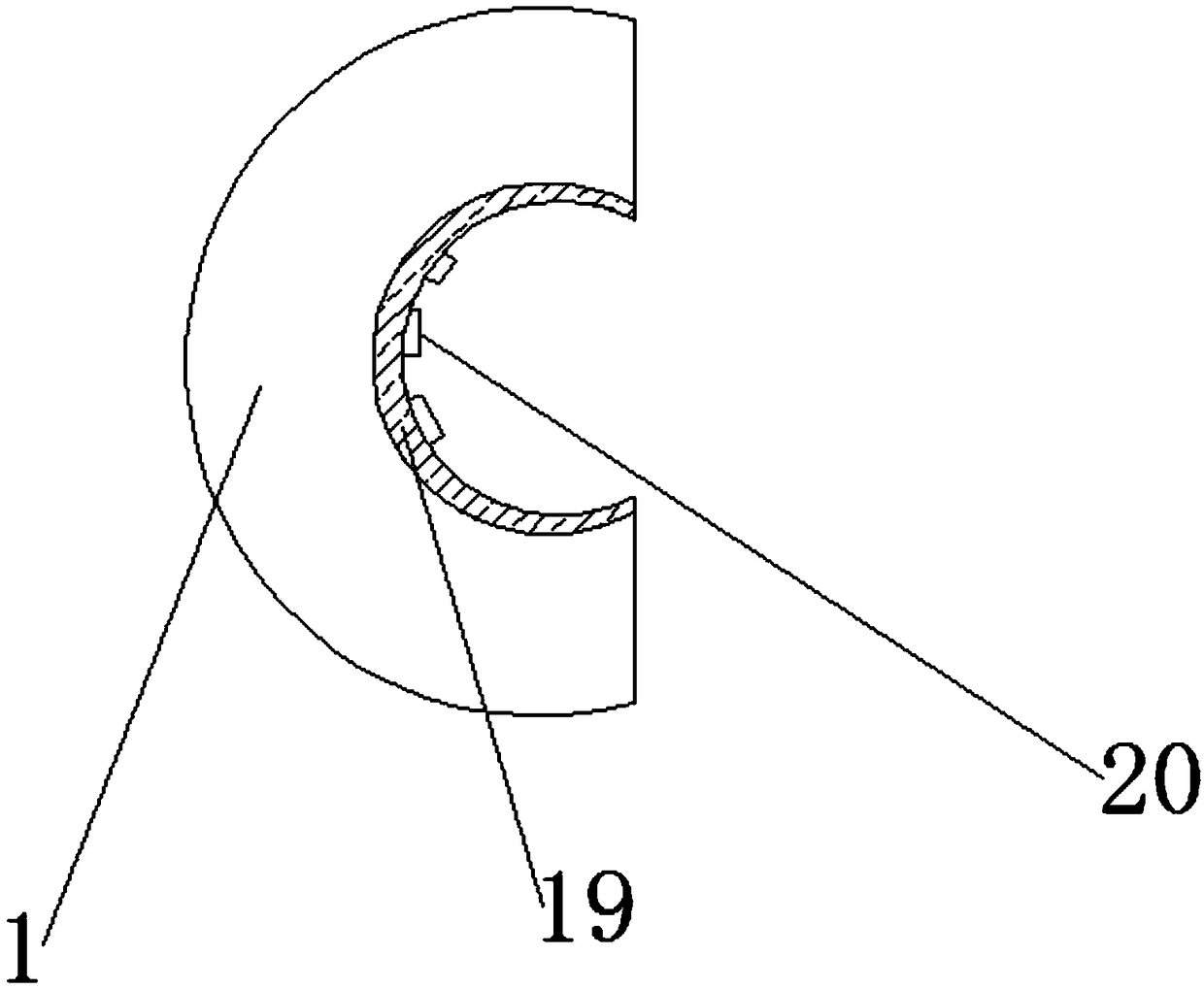

[0022] Example 1: See Figure 1-3 , the present invention provides a technical solution: a magnetic suspension bearing with high reliability, including a bearing main body 1, an electromagnet 2, a stator disc 3, a stator 4, a first damping ring 5, a rotor 6, a magnetic block 7, Limiting groove 8, dynamic monitoring device 9, second damping ring 10, rotor sleeve 11, position monitor 12, stator 2 13, display screen 14, connecting wire 15, start switch 16, fitting block 17, embedded plate 18. The oil storage layer 19 and the guide hole 20, the middle part of the bearing main body 1 is provided with a stator disk 3, the middle part of the side end of the stator disk 3 is provided with a rotor 6, one side of the rotor 6 is provided with a rotor sleeve 11, and the rotor 6 The outer wall is provided with a first damping ring 5, one end of the bearing main body 1 is provided with a dynamic monitoring device 9, one side of the stator disc 3 is provided with an electromagnet 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com