Brake pad and vehicle

A technology of brake pads and brake discs, which is applied in the field of vehicle engineering, can solve problems such as poor heat dissipation, and achieve the effects of improving heat dissipation performance, reducing wind resistance, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

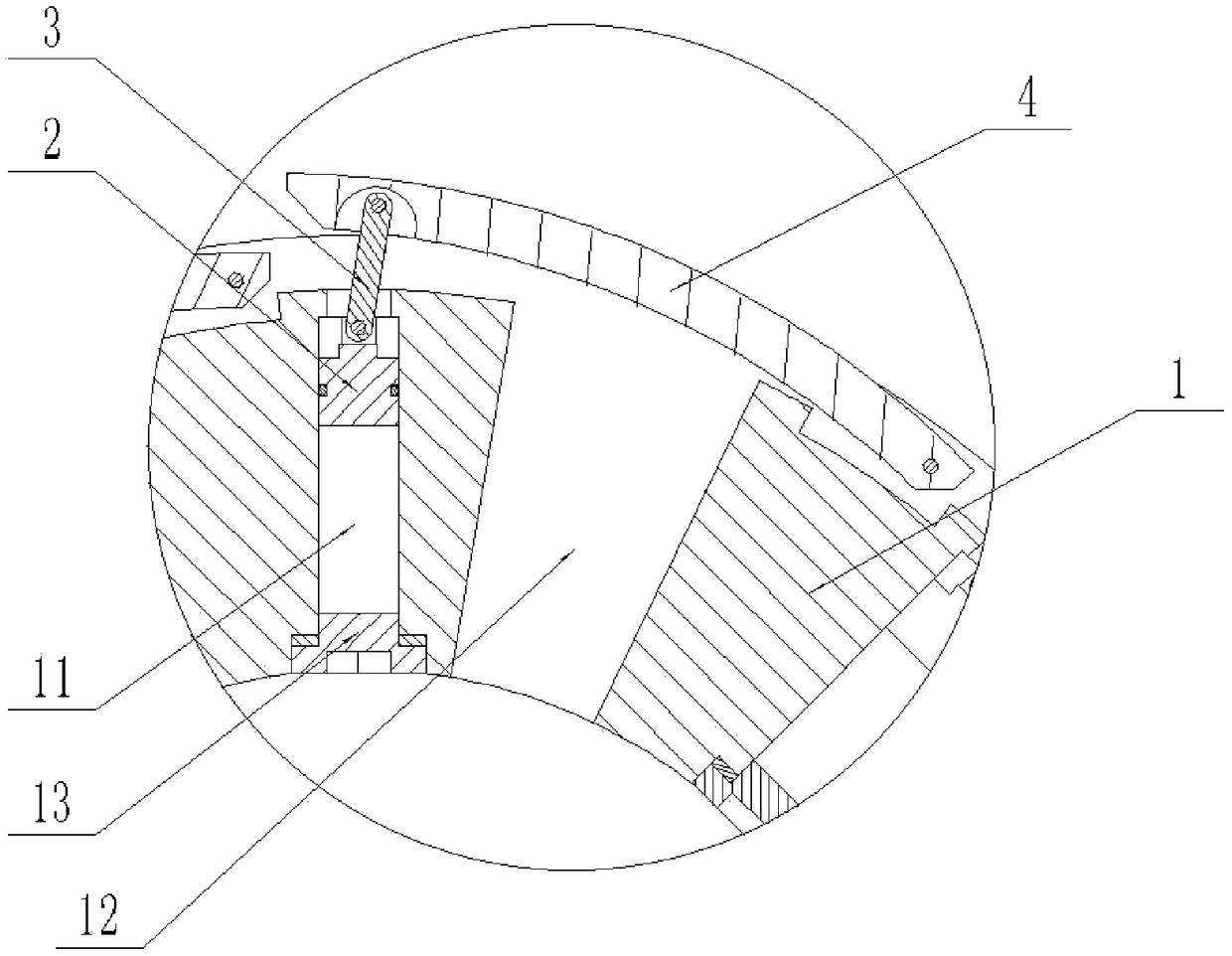

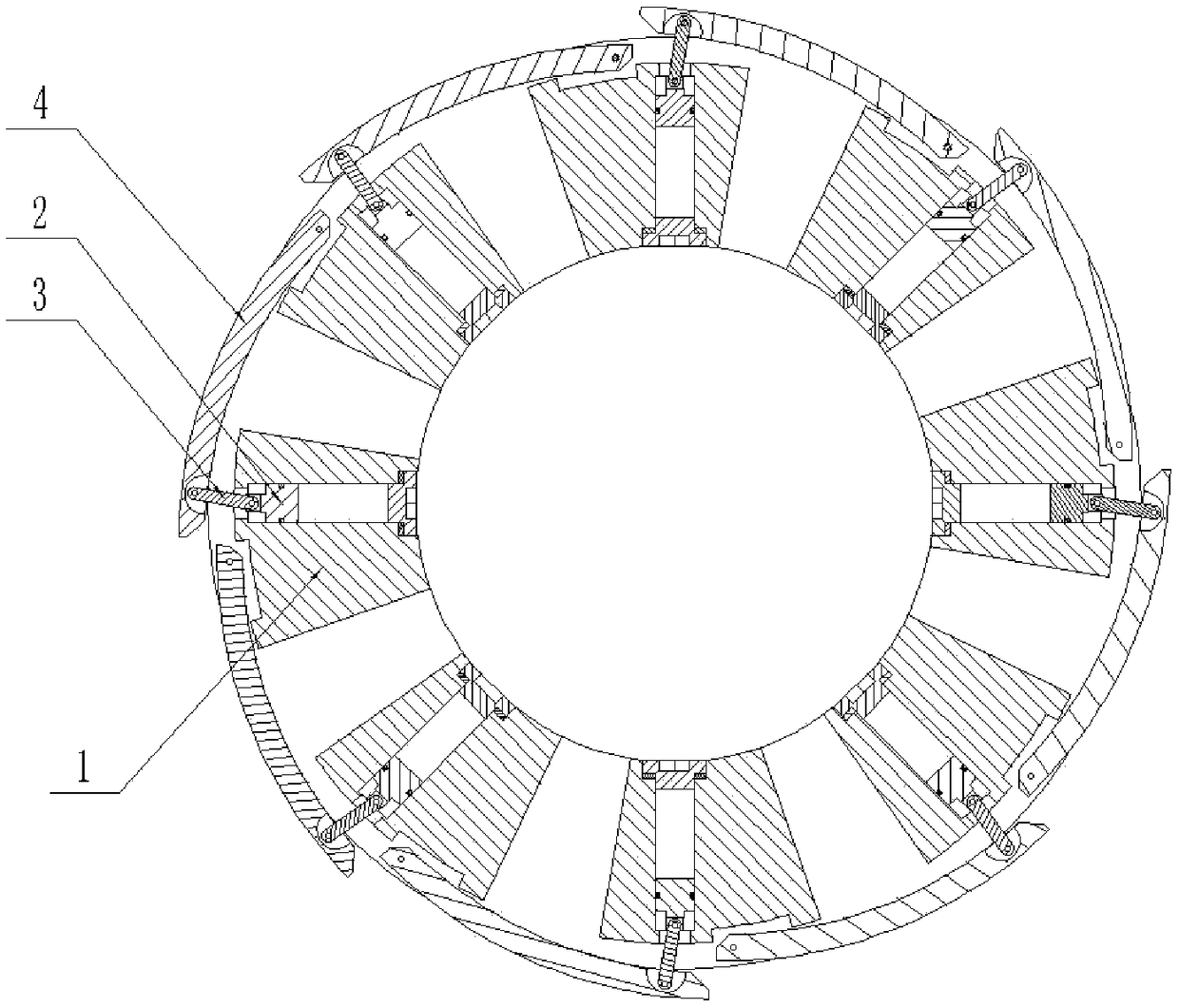

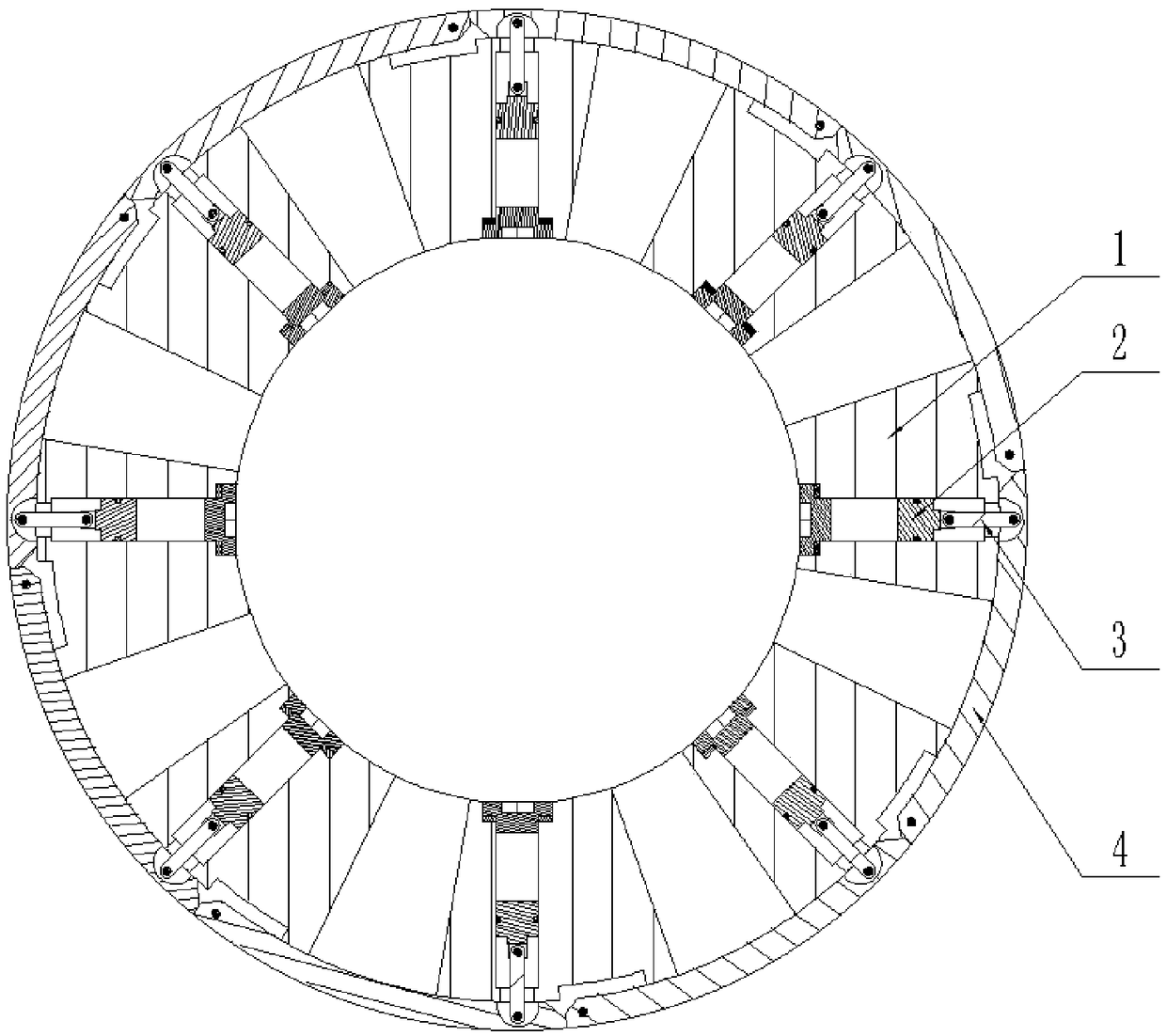

[0031] Such as figure 1 As shown, the brake pad provided by the embodiment of the present invention includes: a brake disc 1, a piston 2, a connecting rod 3 and a windshield 4, the windshield 4 is hinged on the outer peripheral surface of the brake disc 1, and the brake disc 1 A piston hole 11 is provided on the outer peripheral surface, and the piston 2 is inserted into the piston hole 11 . One end of the connecting rod 3 is hinged to the piston 2 , and the other end of the connecting rod 3 is hinged to the windshield 4 .

[0032] Such as figure 2 As shown, a closed space is formed between the piston 2 and the piston hole 11. During the braking process, the friction between the hydraulic caliper and the brake disc 1 generates heat, so that the gas in the closed space between the piston 2 and the piston hole 11 is heated and expands, and the piston The pressure in the hole 11 increases, and the piston 2 is pushed to slide along the piston hole 11 to the end away from the axi...

Embodiment 2

[0048] The vehicle provided in the embodiment of the present invention includes the brake pad provided in the first embodiment. Since the technical effect of the vehicle provided in the present embodiment is the same as that of the brake pad provided in the first embodiment, it is not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com