Flow liquid auxiliary agent automatic conveying device

A technology of automatic conveying device and flow sub-agent, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of the influence of the metering accuracy of the additives, the shaking of the additives in the barrel, etc., to reduce the impact of the metering accuracy. , the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

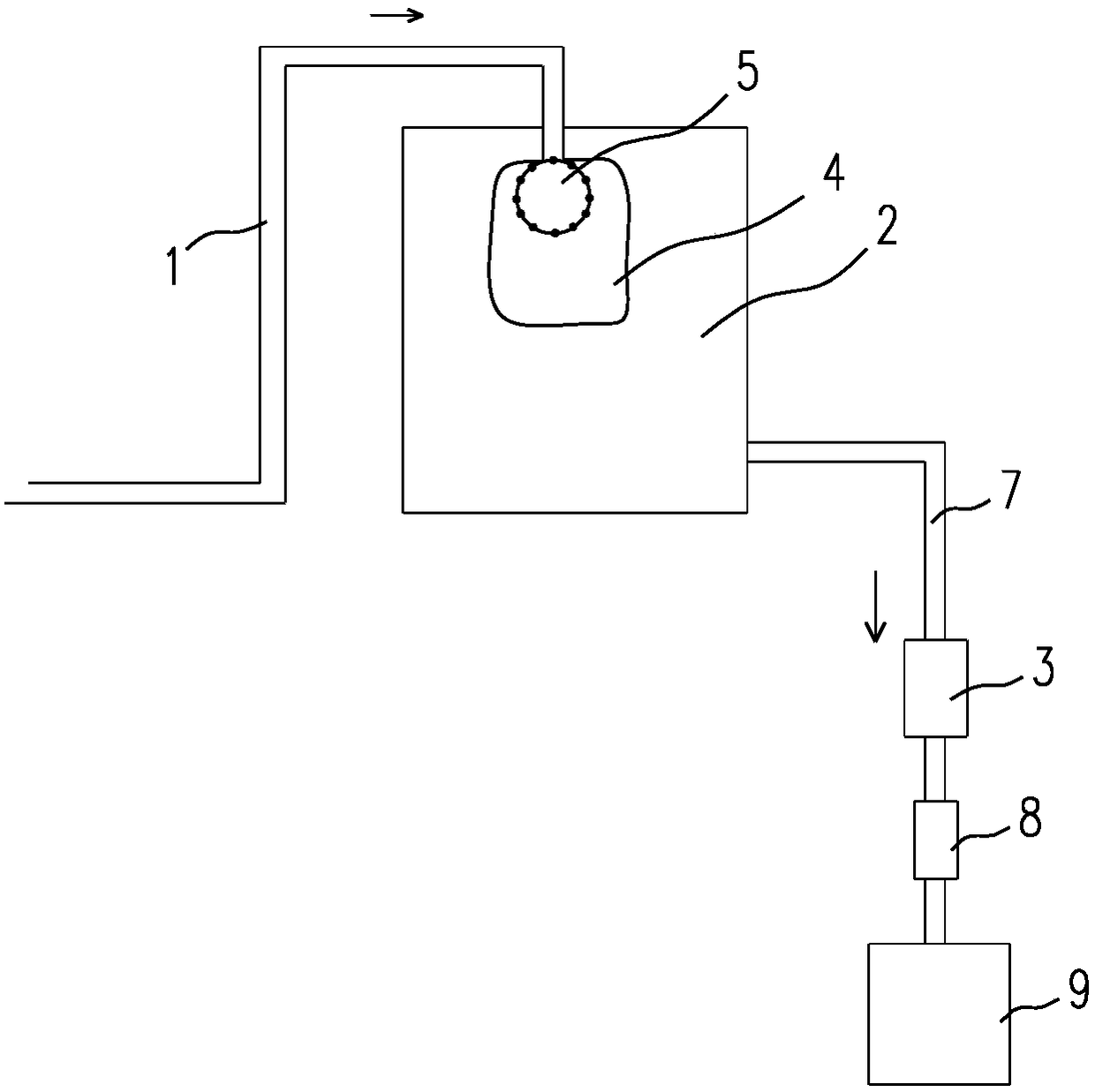

[0020] combine figure 1 with figure 2 As shown, a flow sub-aid automatic delivery device,

[0021] It has an auxiliary agent storage tank 2, a dye tank 9, and a liquid replenishment pipe 1 communicating with the top of the auxiliary agent storage tank 2. The secondary auxiliary agent is transported to the auxiliary agent storage tank 2 through the liquid replenishment pipe 1 for temporary storage. A buffer head 5 is provided on the end of the liquid replenishment pipe 1 inside the barrel 2 , and a buffer bag 4 is sheathed on the outside of the buffer head 5 .

[0022] The buffer head 5 is a shower-type device with multiple liquid outlet channels inside.

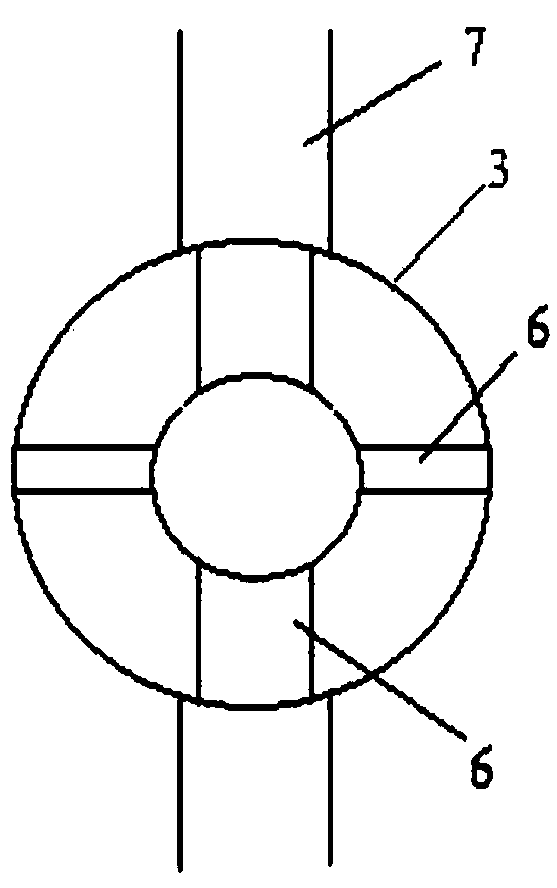

[0023] The auxiliary agent storage tank 2 and the dye tank 9 are communicated through a metering tube 7, and the metering tube 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com