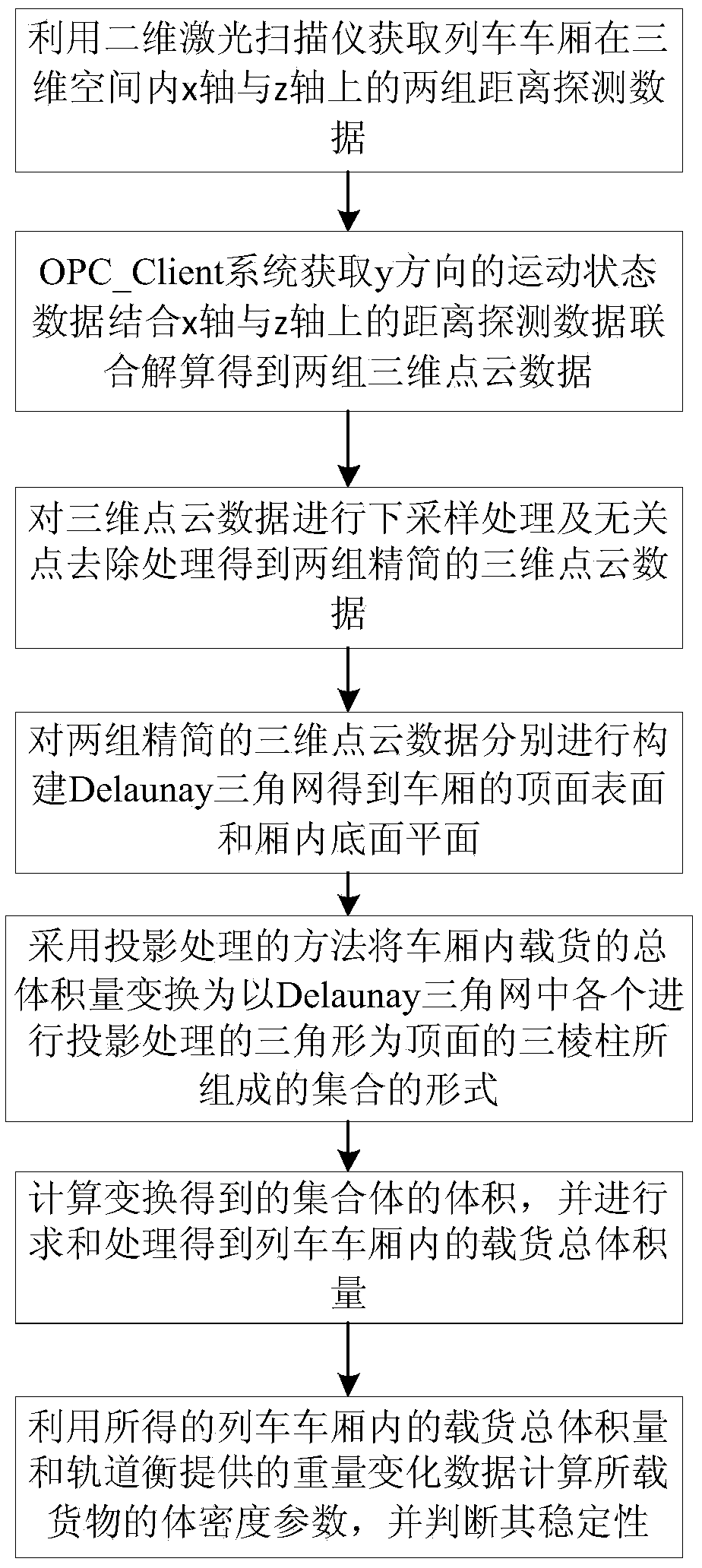

Train compartment cargo volume and bulk density detection method based on point cloud data processing

A technology of point cloud data and volume density, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of high cost and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Step 1. Use two high-precision two-dimensional laser scanners installed at the centerline of the top centerline of the entrance and exit of the dumper room to obtain the state of the heavy vehicle and the state of the empty vehicle loaded with bulk cargo in the three-dimensional space of the x-axis and z-axis. Two sets of distance probe data on the axes.

[0036] Two high-precision two-dimensional laser scanners are respectively installed at the top centerline of the entrance of the dumper room for heavy vehicles and the exit of empty vehicles on the other side, and use the movement of the measured bulk cargo train carriage along the y-axis direction to scan it in real time , to obtain two sets of distance detection data on the x-axis and z-axis in the three-dimensional space of the heavy vehicle state and the empty state of the measured bulk cargo train carriage.

[0037] Step 2. According to the OPC_Client system, collect the motion state information of the measured b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com