sensor

A sensor and sensing surface technology, applied in the field of sensors, can solve problems such as inability to absorb objects, and achieve the effect of improving elasticity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

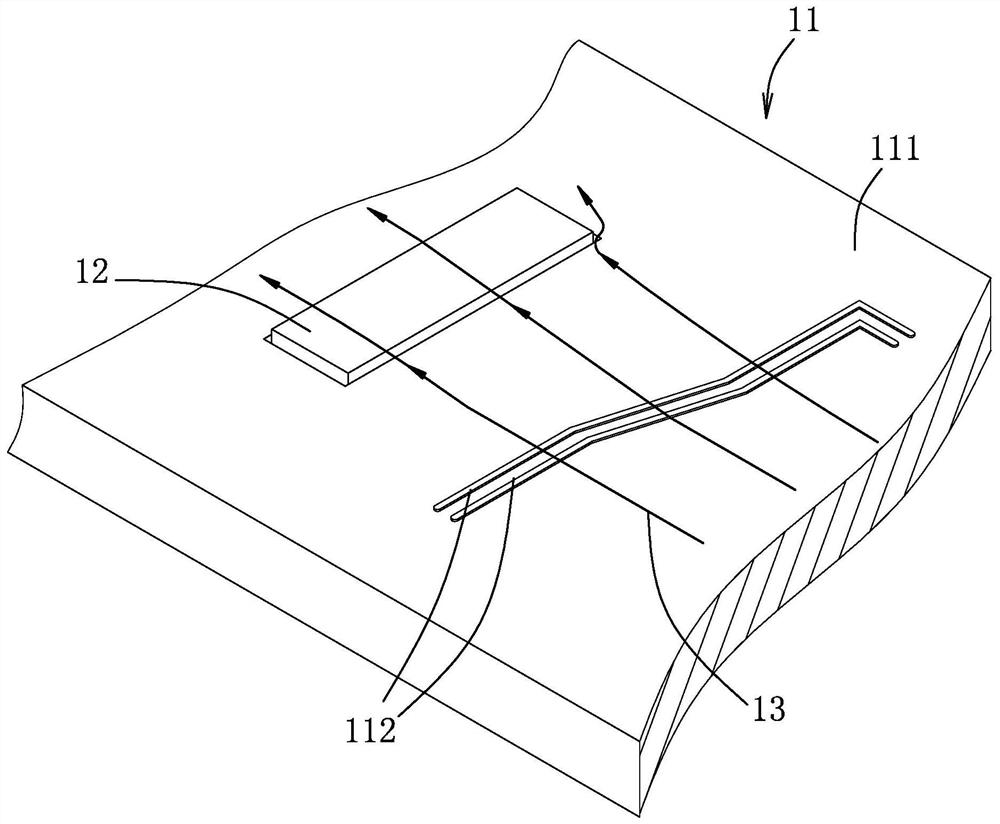

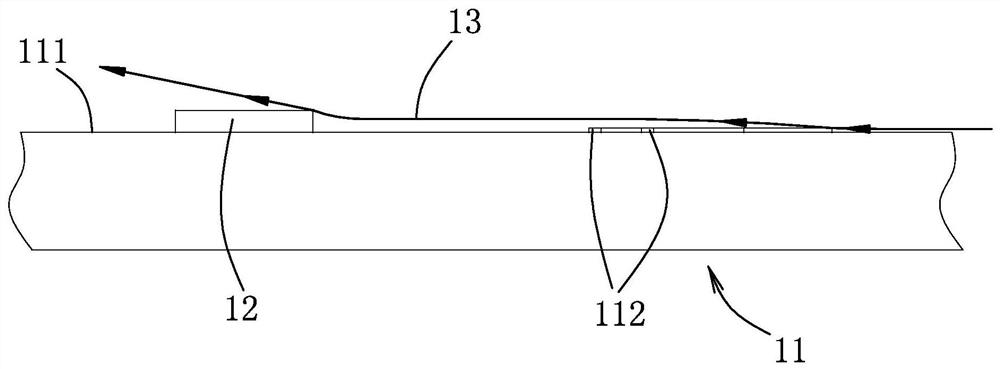

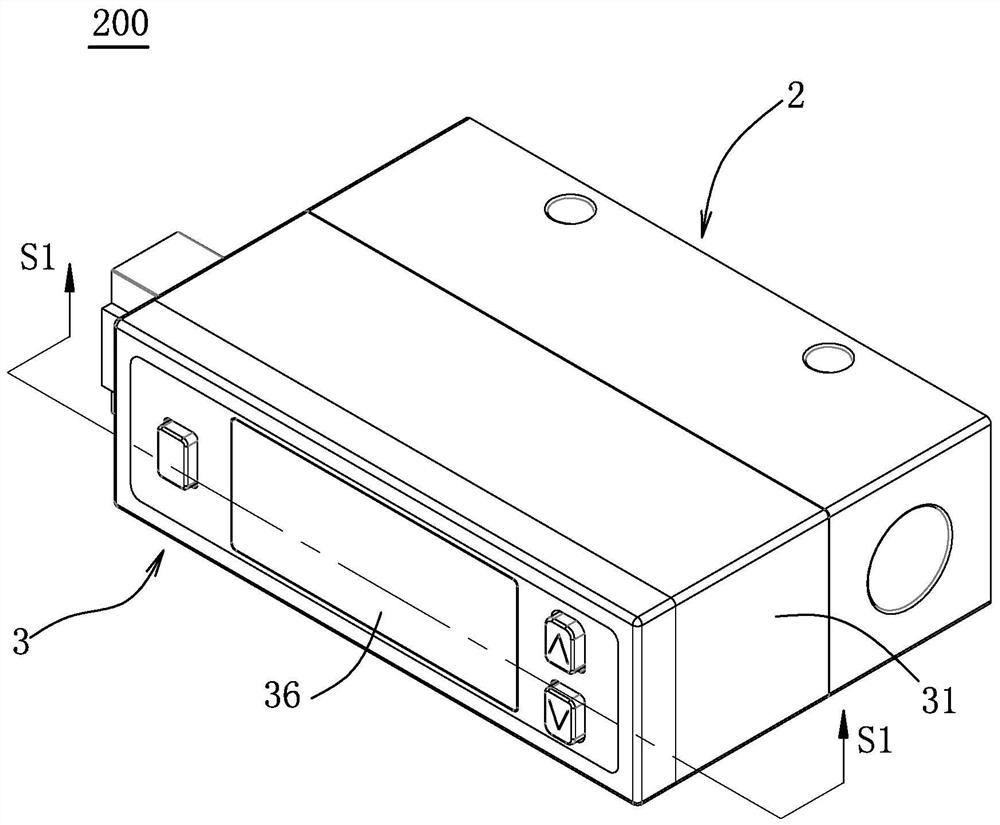

[0043] refer to image 3 , is the first embodiment of the sensor of the present invention, and the sensor 200 is an example of a flow and pressure sensor, which has the function of sensing air flow and pressure. The sensor 200 includes a flow guide housing 2 and a sensing device 3 .

[0044] refer to image 3 , Figure 4 and Figure 5 , the flow guide housing 2 includes a front end surface 21 and two side surfaces 22 , 23 respectively located on the left and right sides of the front end surface 21 . The flow guide housing 2 defines a gas flow path 24, the gas flow path 24 has a first flow path 241, a second flow path 242, a guiding flow path 243, a first guiding flow path 244, a second guiding flow path A flow path 245 , a branch flow path 246 , and a diversion hole 247 . The first flow path 241 is formed on the side surface 22 for inserting an air inlet pipe (not shown in the figure), so that the air inlet pipe can deliver the gas flow into the gas flow path 24 through t...

no. 3 example

[0064] refer to Figure 13 , is the third embodiment of the sensor of the present invention. The overall structure and sensing principle of the sensor 200 are roughly the same as those of the first embodiment, except for the location of the through hole 333 and the pressure sensing chip 324 .

[0065] In this embodiment, the through hole 333 communicates with the first conduction flow path 244 of the flow guide housing 2 , and the pressure sensing chip 324 is aligned with the through hole 333 and closes the through hole 333 . In this way, the pressure sensing chip 324 can sense the pressure of the airflow flowing into the through hole 333 through the first conduction flow path 244 .

[0066] refer to Figure 14 , is the fourth embodiment of the sensor of the present invention. The overall structure and sensing principle of the sensor 200 are roughly the same as those of the first embodiment, except for the location of the pressure sensing chip 324 .

[0067] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com