Temperature sensor calibration method against reverse Early effect

A temperature sensor and Early effect technology, used in thermometer testing/calibration, thermometers, instruments, etc., can solve the problems that the test environment is difficult to meet the sensor calibration requirements, the difficulty of sensor calibration, etc., to reduce the test condition requirements and test costs, The effect of avoiding the need for a high-precision temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

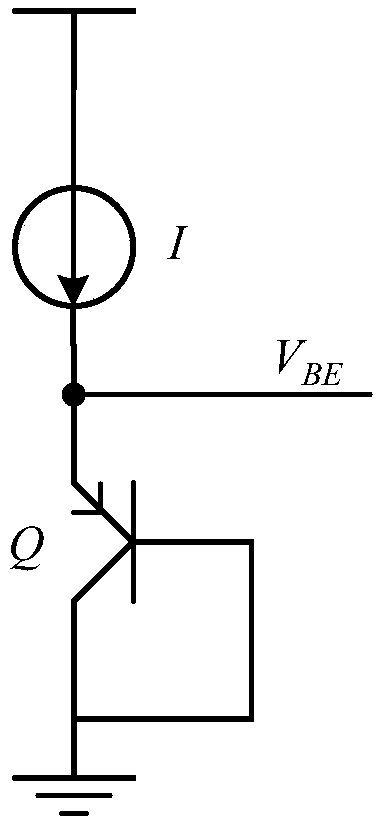

[0059] figure 1 It is a PNP transistor Q with the common ground of the collector and the base flowing through a bias current of I, and the voltage between the emitter and the collector can be expressed as

[0060] V BE =V BE0 +λ·T+c(T) (1)

[0061] where V BE0 V at absolute zero BE The size of λ is V BE The first-order temperature characteristic of , T is the absolute temperature, c(T) is V BE The higher-order temperature part of .

[0062] V BE The main error of λ is its first-order temperature coefficient λ, so in temperature sensors, usually only the deviation of λ needs to be corrected. However, when the accuracy of the temperature sensor is required to be high enough, or when the reverse Earley effect of the bipolar tube varies greatly under different process corners in some processes, the reverse E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com