An elevator special flat cable with flame retardant function

A technology for flat cables and elevators, which is applied in the field of special flat cables for elevators. It can solve the problems of no fire resistance, waste of resources, fires in flat cables, etc., and achieve good shock absorption and buffer performance, easy maintenance and replacement, and good heat dissipation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

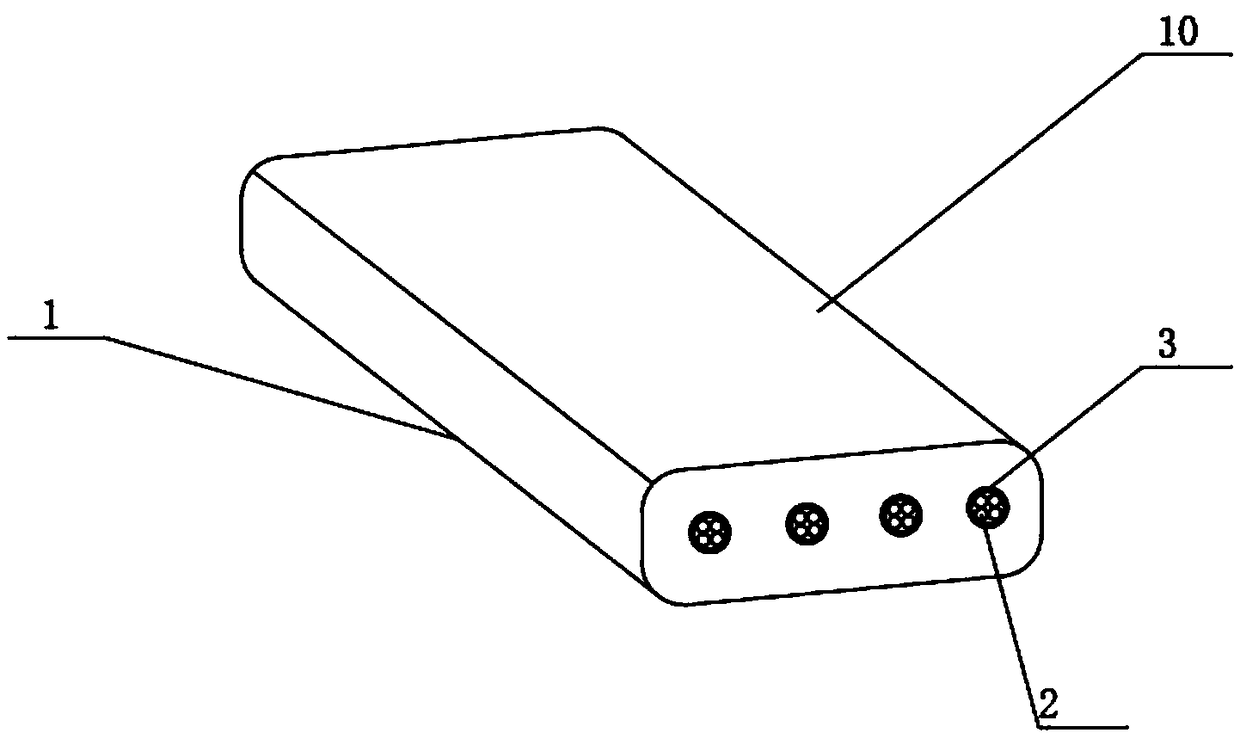

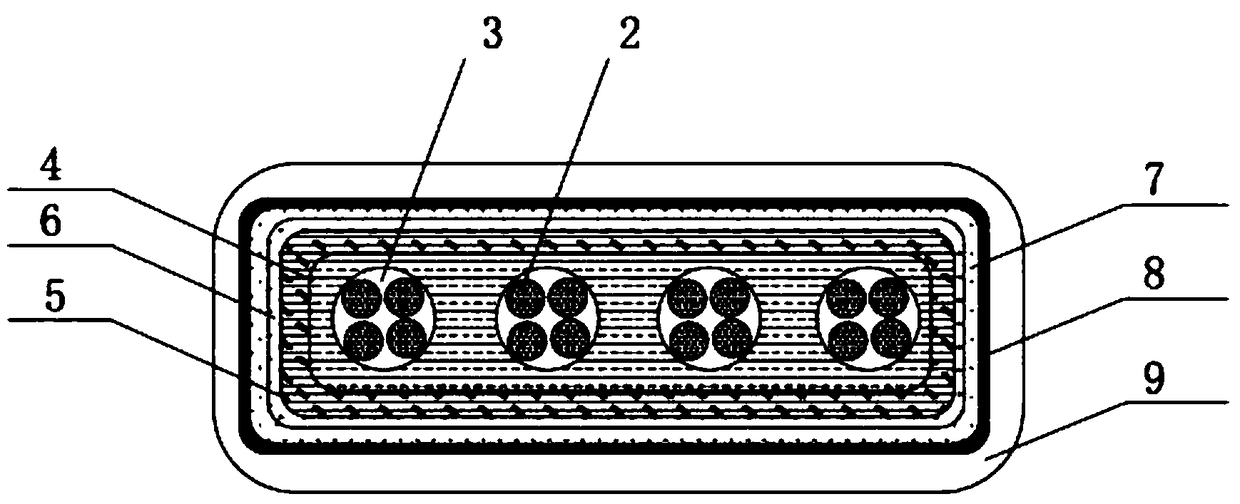

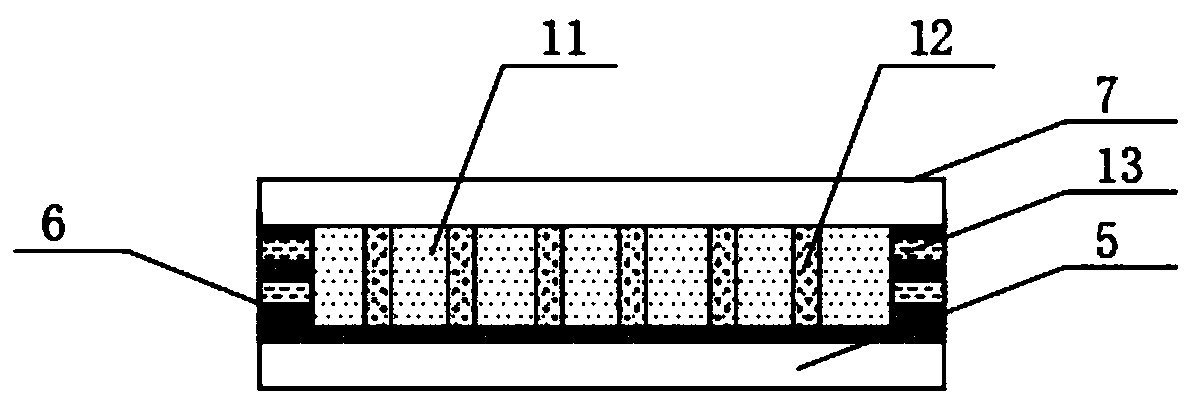

[0020] Such as Figure 1-Figure 4 As shown, a special flat cable for elevators with a flame-retardant function proposed by the present invention includes a flat cable body 1, a cable core 2 is arranged inside the flat cable body 1, and a braided layer 3 is fixedly installed on the outside of the cable core 2. The outer side of the layer 3 is fixedly equipped with a protective cover 4, the outer side of the protective cover 4 is provided with a first insulating layer 5, and the outer side of the first insulating layer 5 is fixedly installed with a flame-retardant layer 6, and the flame-resistant layer 6 includes flame-retardant fibers 61 and flame-retardant Fire retardant 62, and the bottom of flame retardant layer 6 is provided with flame retardant fiber 61, and the upper surface of flame retardant fiber 61 is fixedly installed with fire retardant glue 62, and the both sides of fire retardant glue 62 are evenly opened with cooling holes 13, by setting the fire retardant The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com