Afforestation wagon

A technology of afforestation and trolley, which is applied in the field of agricultural and forestry machinery, can solve the problems of respiratory hazards and manpower loss, and achieve the effect of large force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

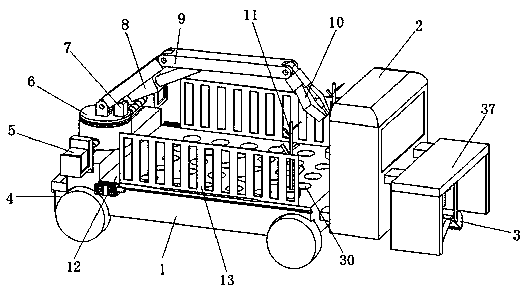

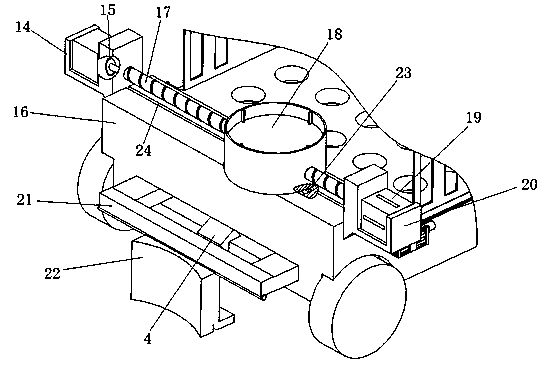

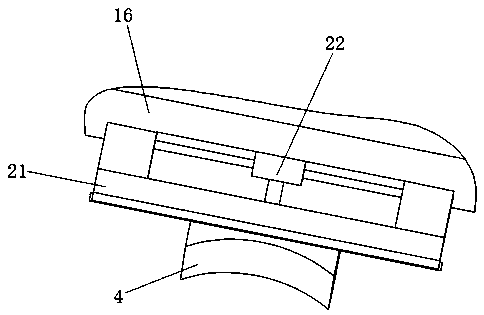

[0030] Example: a tree planting afforestation trolley, the composition is as attached Figure 1-11 As shown, the vehicle body 1 is included, which can be the vehicle body 1 of an ordinary truck. The vehicle body 1 is provided with a sapling holding base 12, which is made of stainless steel plate. The sapling holding base 12 is fixed on the vehicle body 1 by bolts. A number of circular grooves 30 are provided on the holding base 12, and the circular grooves 30 are arranged in an equidistant matrix. The roots of the saplings 11 are arranged in the circular grooves 30, so that the saplings 11 placed on the cart can be better fixed. The spacing between the grooves 30 can facilitate the clamping jaws 10 to grip the saplings 11 and prevent the saplings 11 from being stacked together and causing interference. A protective door 13 is hinged on both sides of the sapling holding base 12, which can prevent the sapling 11 from accidentally tipping over and falling off the trolley during tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com