Automatic shelling machine of prawns as well as shelling method of automatic shelling machine

A sheller and automatic technology, applied in the processing of crustaceans, shrimp/lobster processing, slaughtering, etc., can solve the problems of slow efficiency and inability to meet the processing work of sea shrimp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

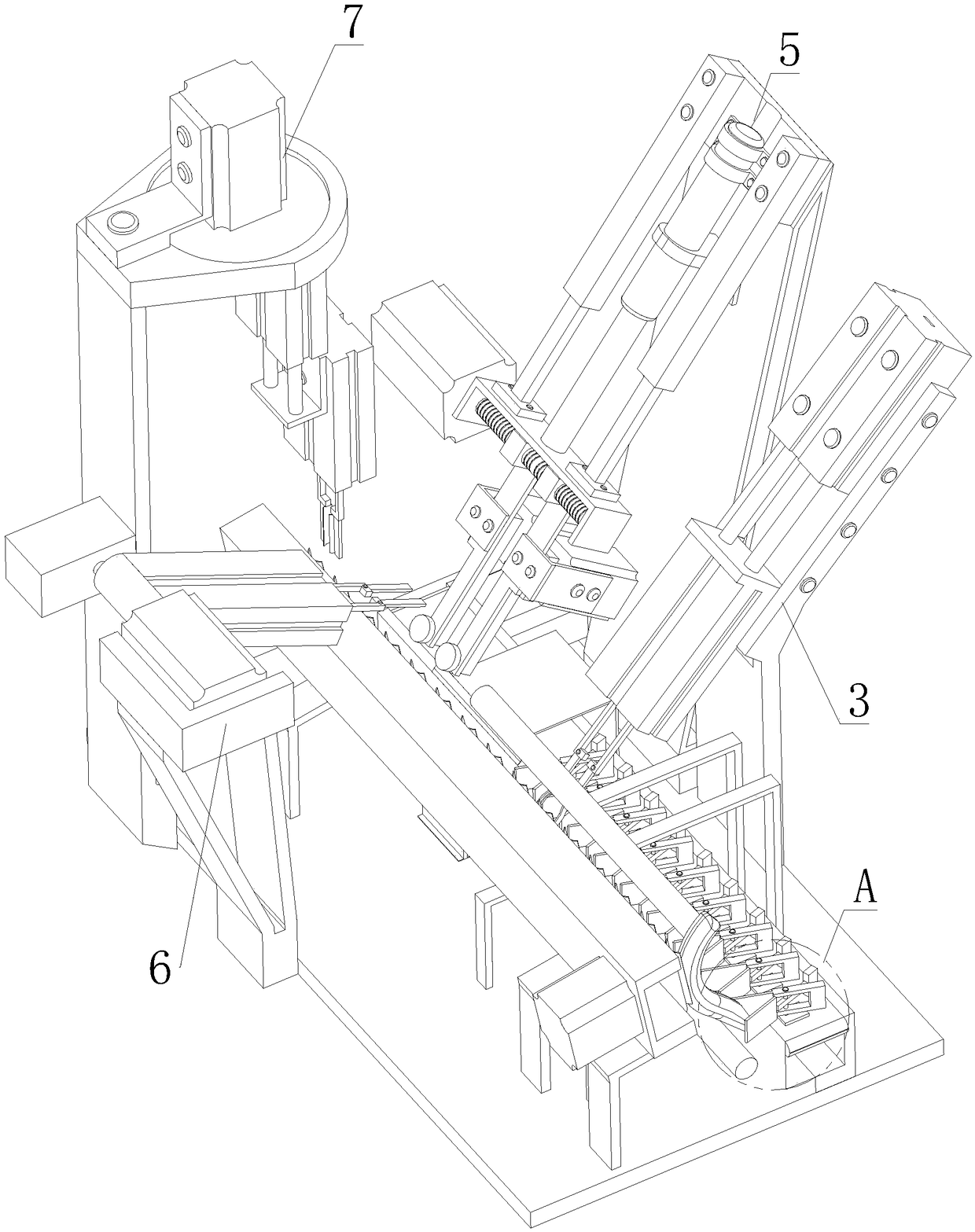

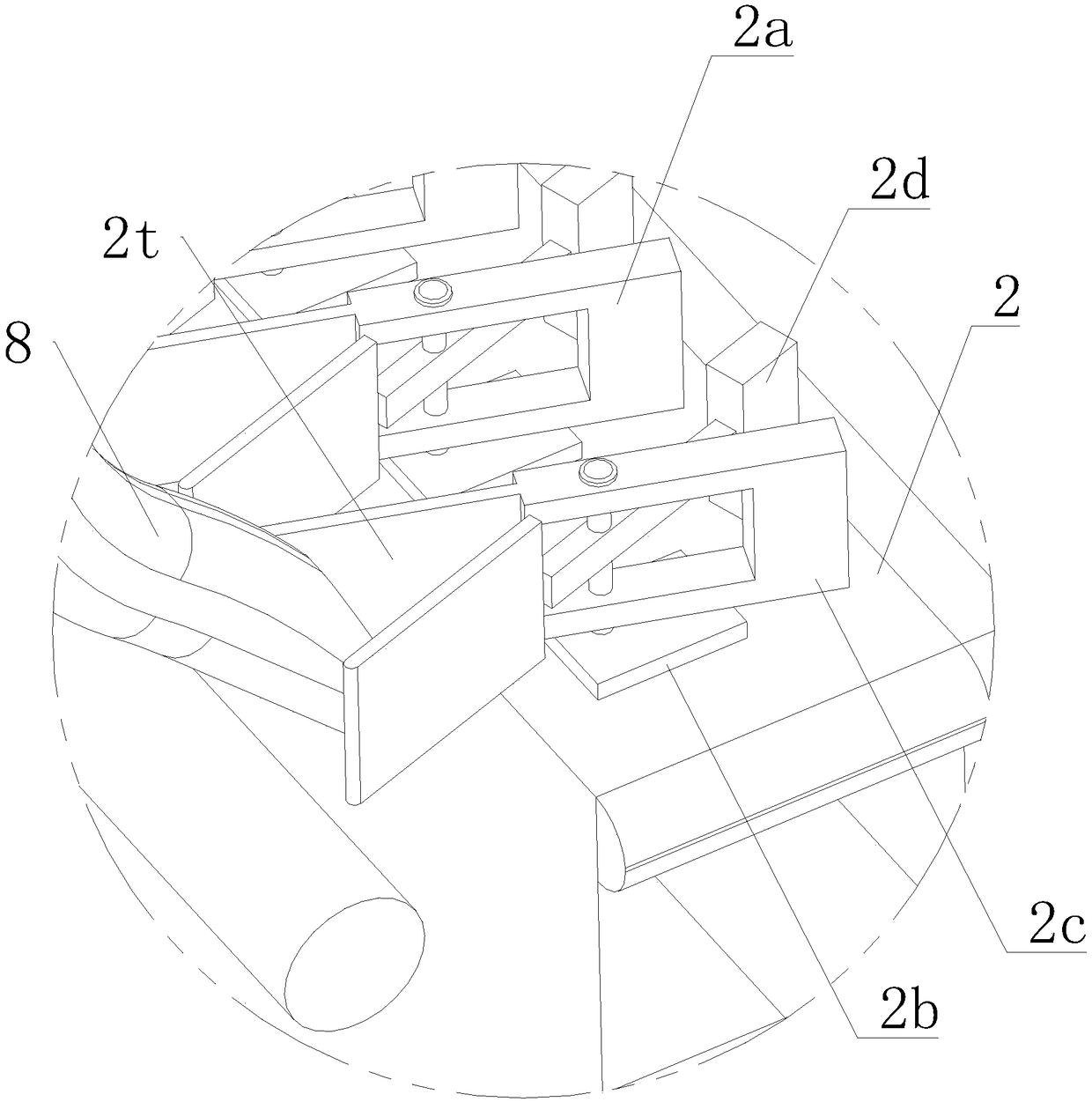

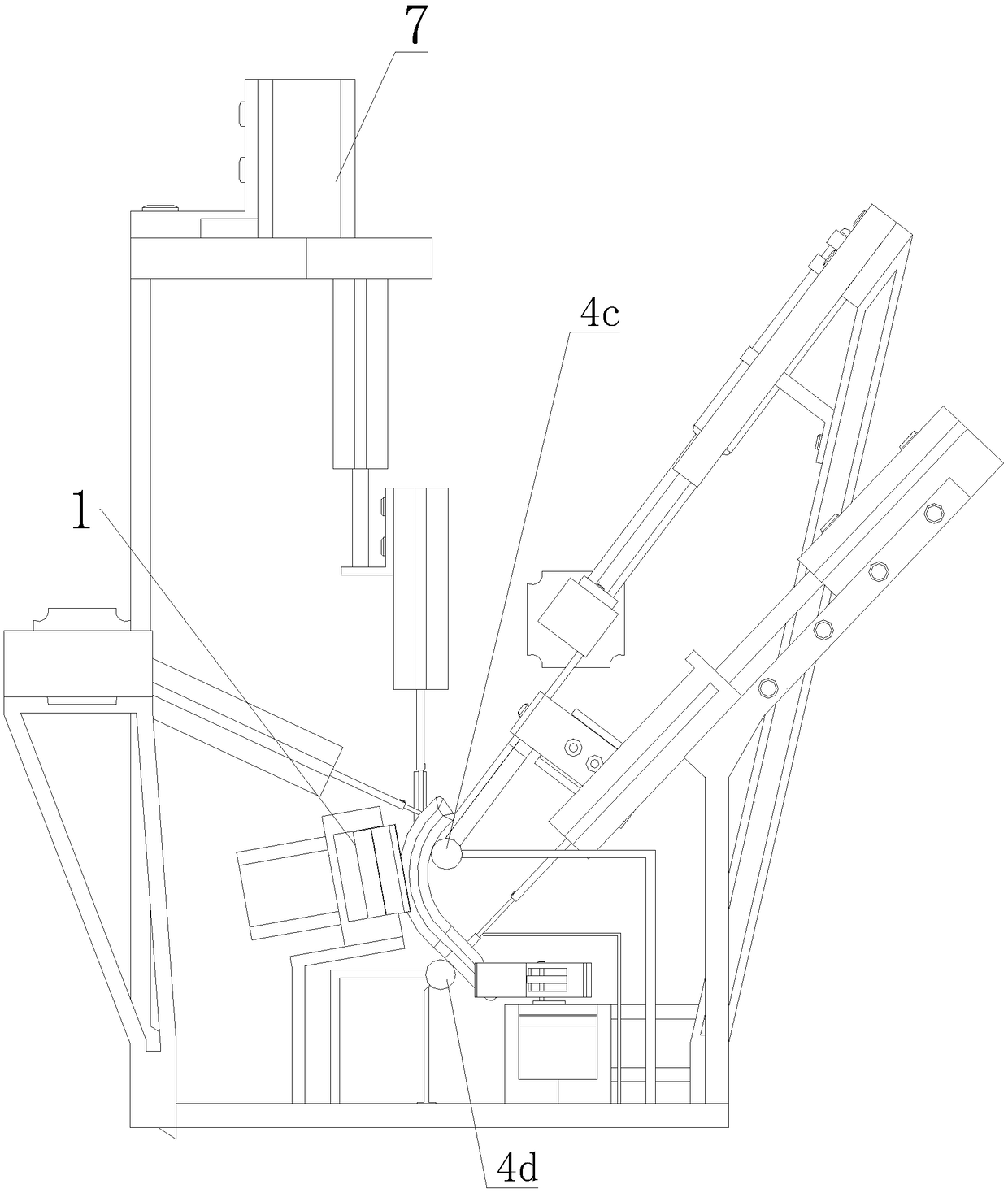

[0043] refer to Figure 1 to Figure 12 A kind of sea shrimp automatic peeling machine shown, comprises processing table, and peeling machine includes feeding conveyer belt 1, auxiliary conveyer belt 2, primary pinching device 3, passive cutting device 4 and pre-shelling device 5, feeding conveyer belt 1 is erected obliquely above the processing table, and the auxiliary conveyor belt 2 is horizontally installed below the side of the feeding conveyor belt 1, and the conveying planes of the two form an obtuse angle of 115 degrees. The conveying plane of the feeding conveyor belt 1 and the auxiliary conveyor belt 2 There are several first jigs 1a and second jigs 2a arranged at equal intervals along the conveying direction, and the conveying directions of the two are parallel. The primary pinching device 3 and the pre-pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com