Bidirectional spiral winding roll brush and manufacturing process thereof

A two-way spiral and manufacturing technology, applied in the direction of brushes, brush bodies, bristles, etc., can solve the problems of poor use effect and inability to transport dust on both sides, and achieve the effect of improving the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

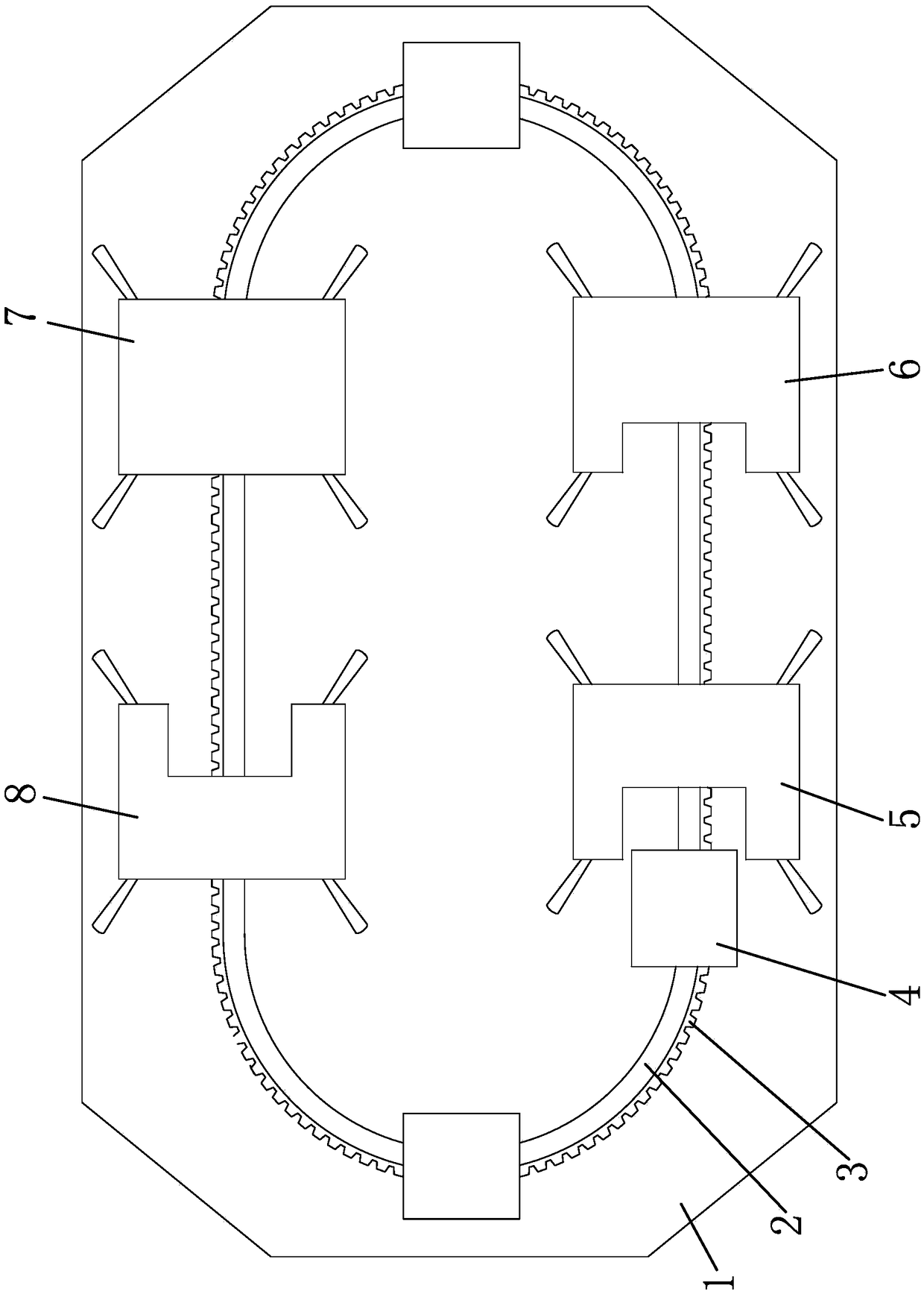

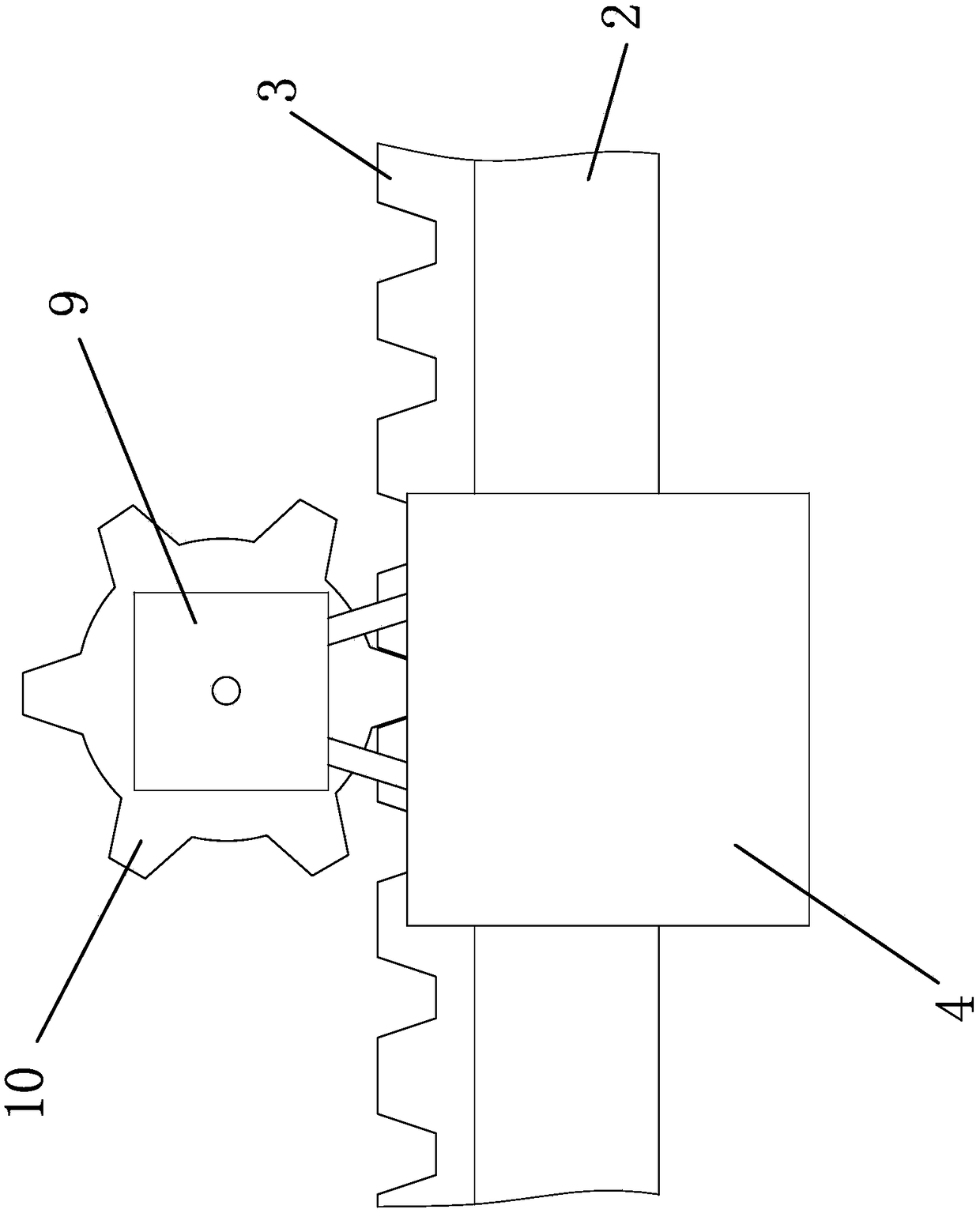

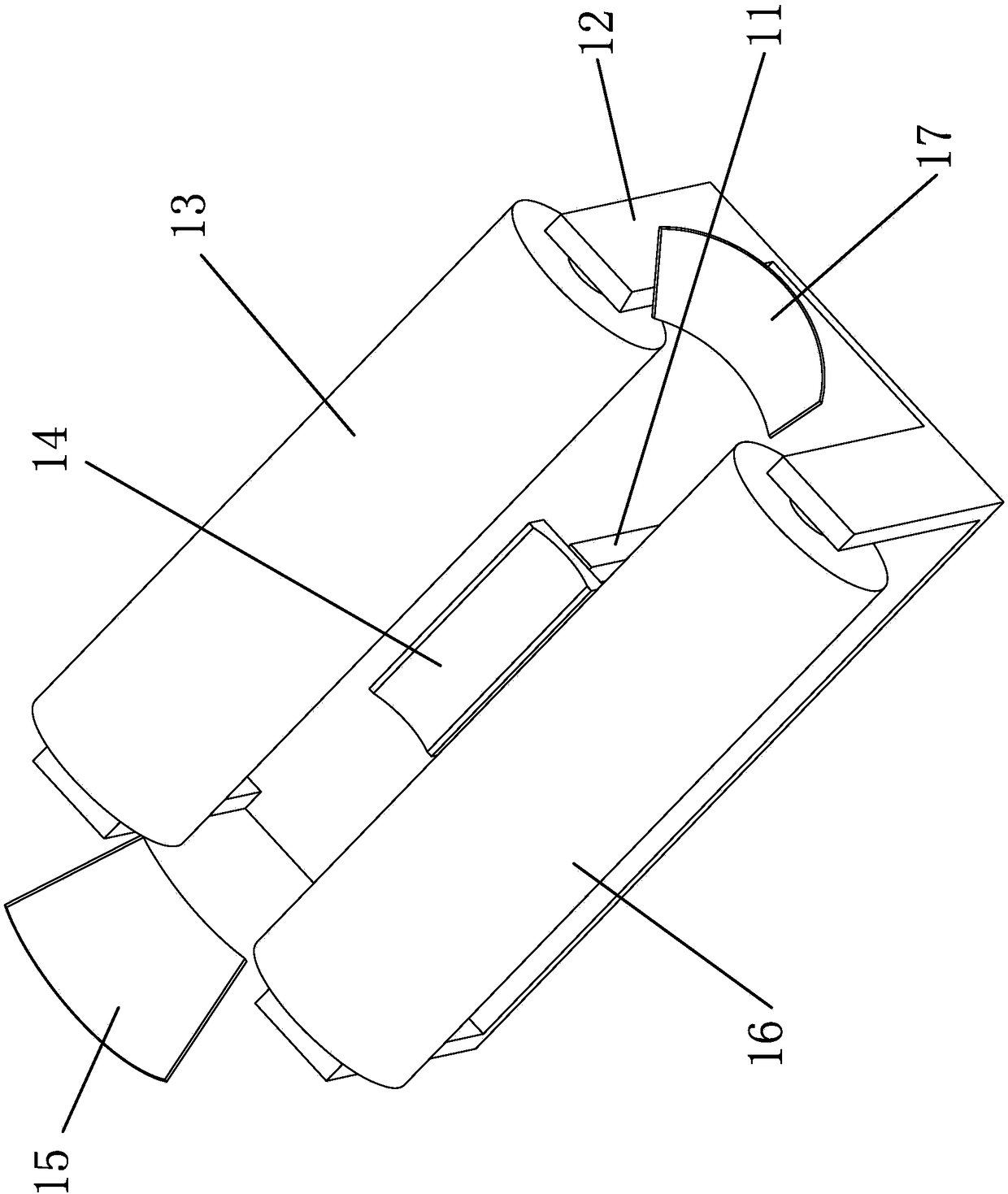

[0048] The two-way spiral winding roller brush includes a roller brush shaft, on which a wool strip is fixed, and the wool strip forms a spiral structure. Taking the length center of the roller brush shaft as the reference, the spiral structure of the brush strip is provided with two sets of mirror images. The wool top includes a wool top body, and the wool top body has vertically arranged hard wool strips and vertically arranged soft wool strips; the ratio of the width of the hard wool strips to the width of the soft wool strips is 1:5-1:10; in this embodiment, The ratio of the width of the hard wool strip to the width of the soft wool strip is 1:7.

[0049] The manufacturing process of the two-way spiral winding roller brush is characterized in that it includes the following steps: a, material preparation: preparing the roller brush shaft and ribbon; b, making tops: spraying glue, drying, hot-melt adhesive and die-cutting the ribbon , make top; in the present embodiment, wha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com