High wear resistant casting blade group for stirrer

A high wear-resistant, mixer technology, applied in mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems of poor corrosion resistance and unstable structure, and achieve strong wear resistance, easy replacement, and increased use range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

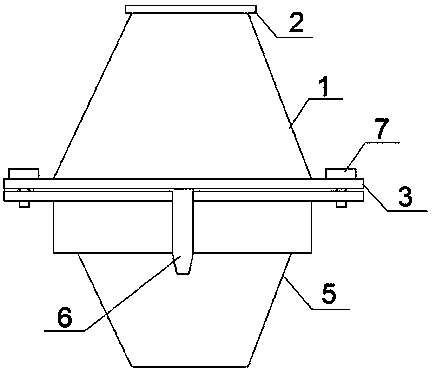

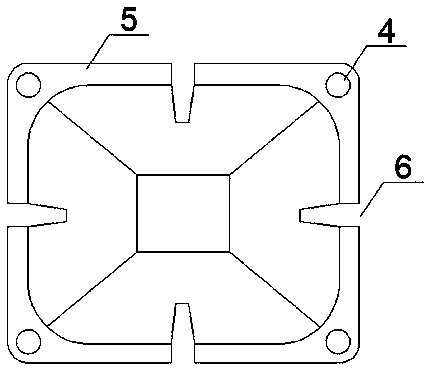

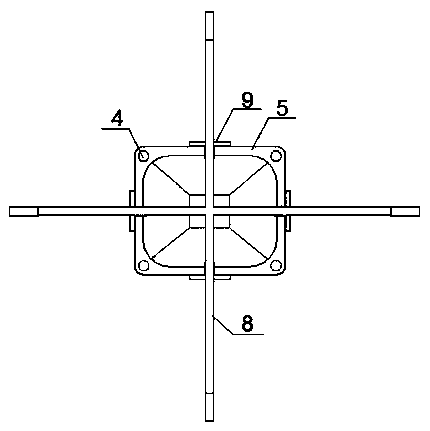

[0021] Such as Figure 1-4 As shown, the present invention discloses a high wear-resistant casting blade set for a mixer, including: an upper clamping plate 1, a connecting plate 2, a fixing plate 3, a threaded hole 4, a lower clamping plate 5, a limiting groove 6, bolts 7, and blades 8 , Baffle plate 9, the upper port of described upper splint 1 is welded with connecting plate 2, the lower port of described upper splint 1, the upper port of lower splint 5 are respectively welded with fixed plate 3, described fixed plate 3 four corners Threaded holes 4 are evenly opened at the place, and limit grooves 6 are set on the four surfaces of the lower clamping plate 5, and cross-shaped blades 8 are placed in the limit groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com