Plate machining center

A sheet metal processing and plate turning technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inability to perform positive and negative hemming, the plate cannot be processed, and the degree of automation is low. The effect of machining efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

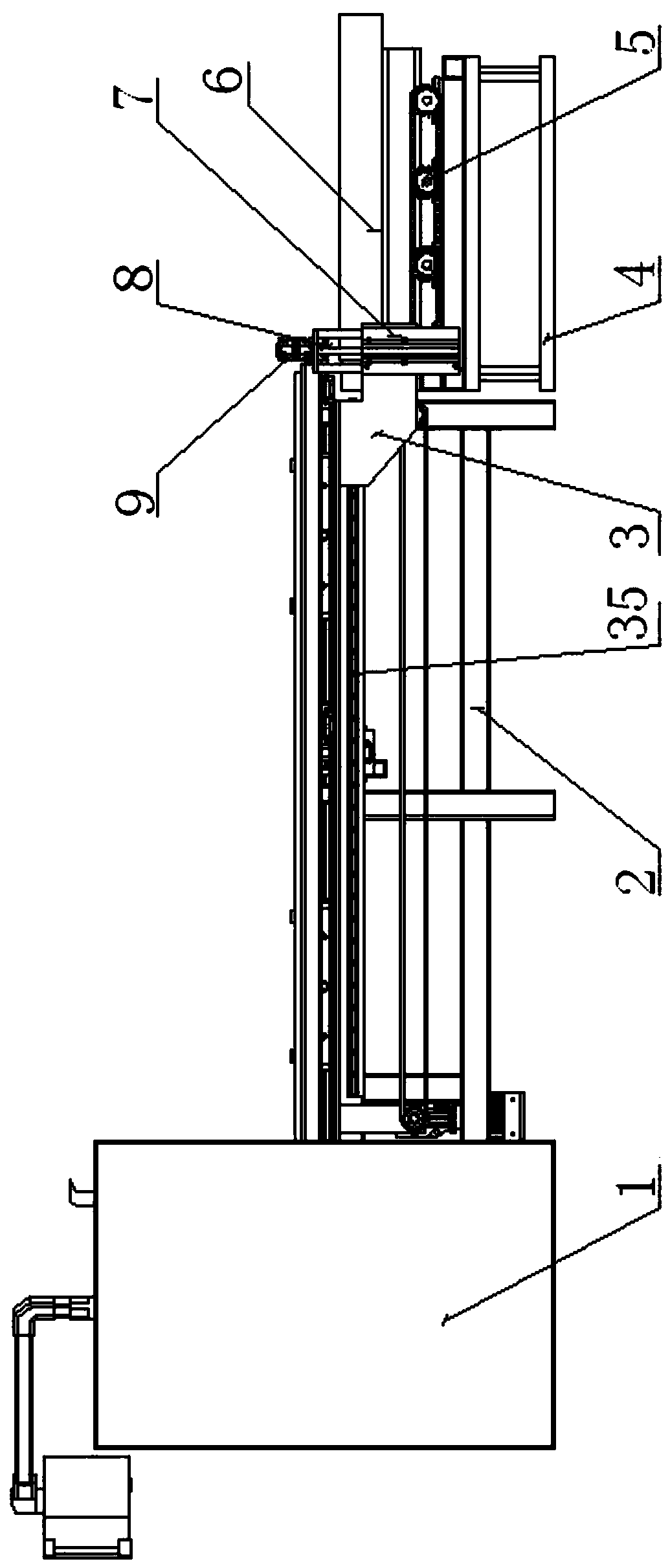

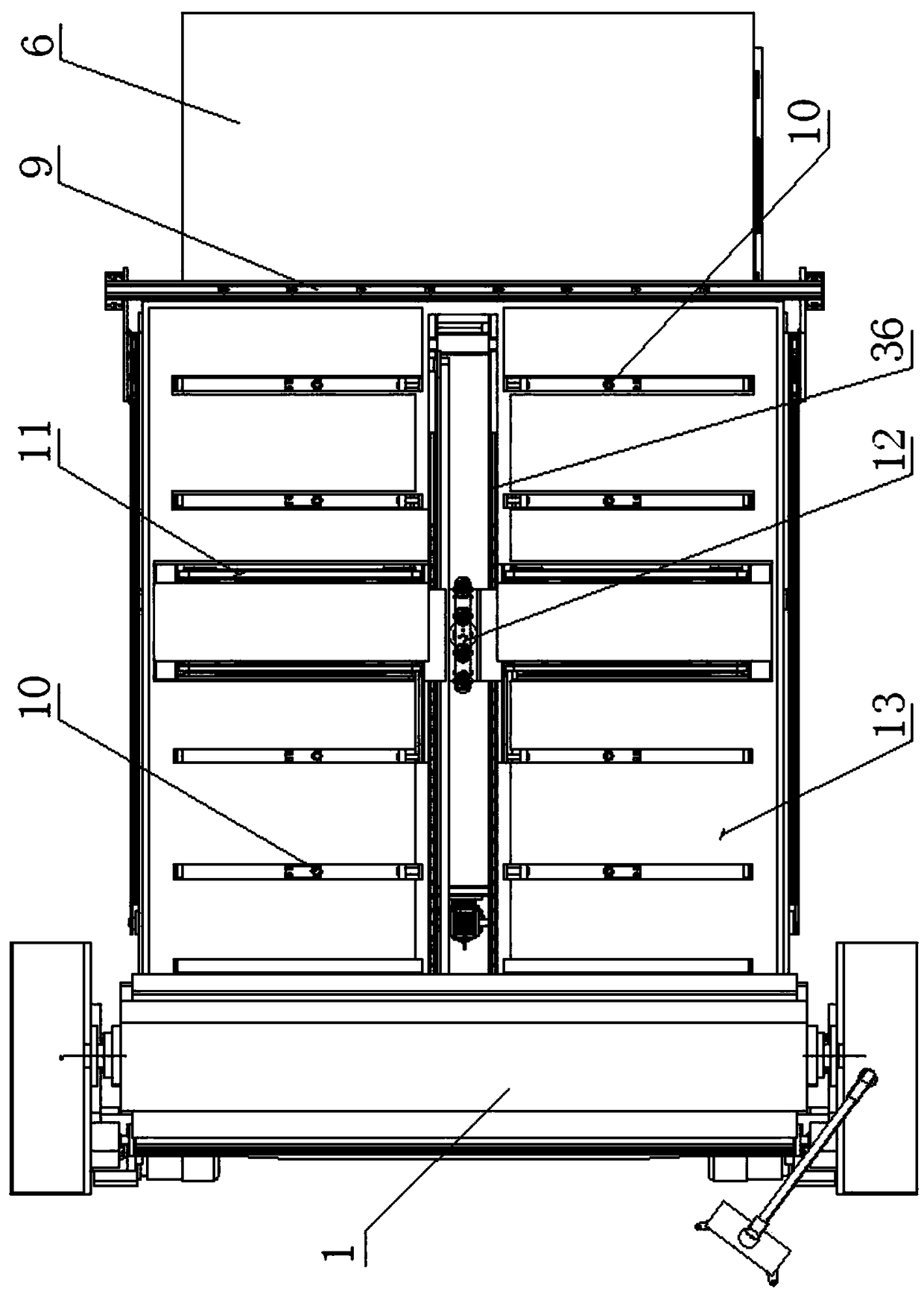

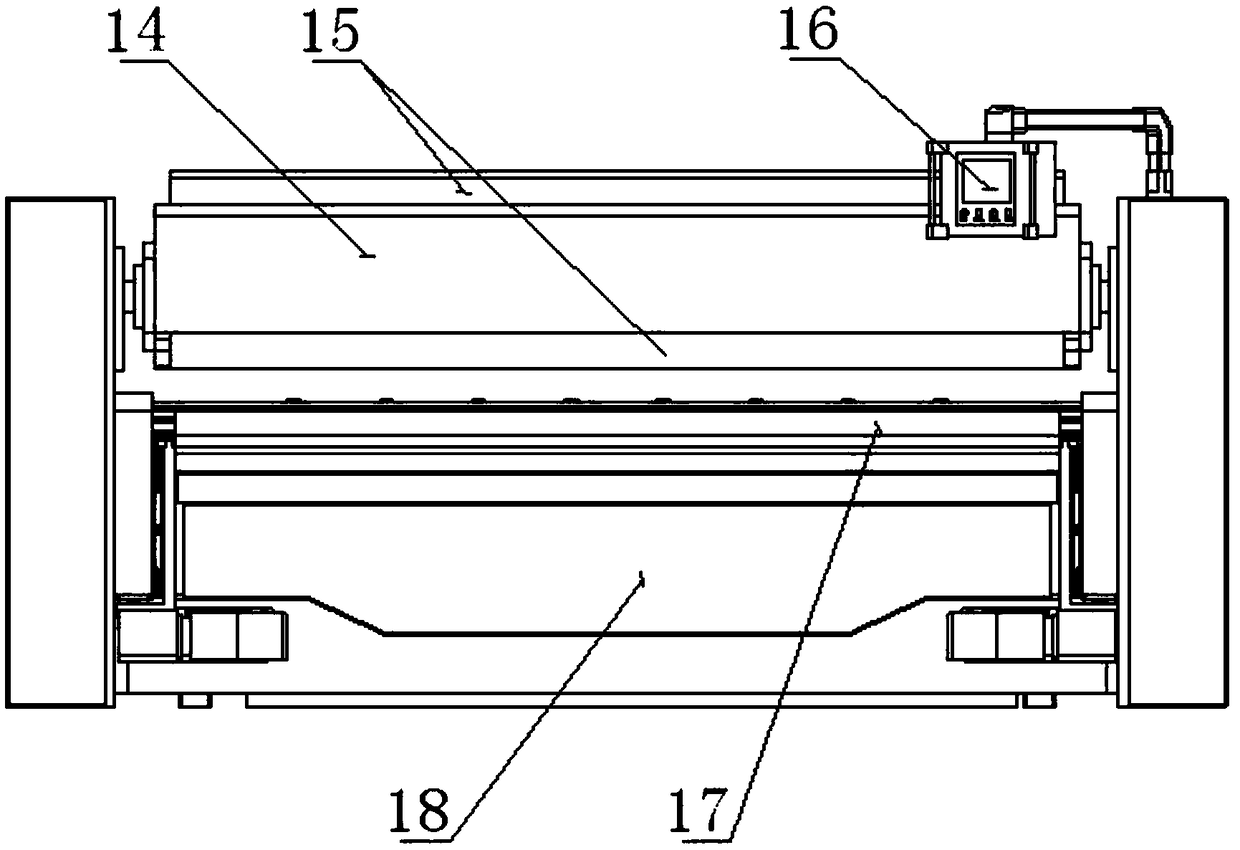

[0025] Below by non-limiting embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0026]As shown in the accompanying drawings, a plate processing center includes a hydraulic lifting table 4, a feeding table frame 2, and a hemming main machine 1 arranged in sequence. The hydraulic lifting platform 4 is a prior art, such as a scissor type hydraulic lifting platform in the prior art, which can be lifted and lowered automatically. The hydraulic lifting platform 4 is provided with a roller moving trolley 5, on which rotatable rollers are arranged, and the rollers rotate through a chain drive for positioning of conveying raw materials. The roller mobile trolley 5 is provided with a raw material platform 6 for placing raw materials. Described loading platform frame 2 is frame structure, is provided with guide rail A35 on both sides of described loading platform frame 2, and sucker elevating crossbeam 9 straddles above described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com