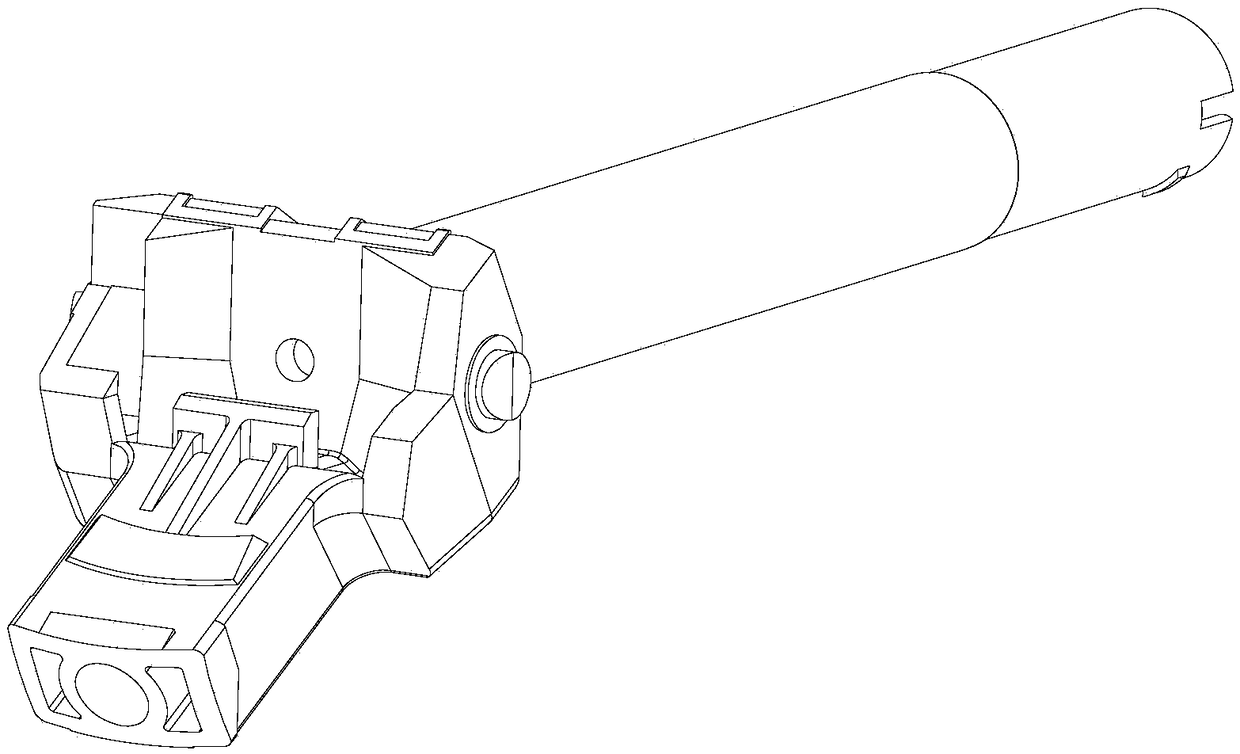

Automobile handle lever forming structure

A molding structure and handle rod technology, which is applied to household components, household appliances, and other household appliances, can solve the problem that the molding mold structure cannot form mounting holes, etc., and achieve the effect of ingenious structural design and guaranteed processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

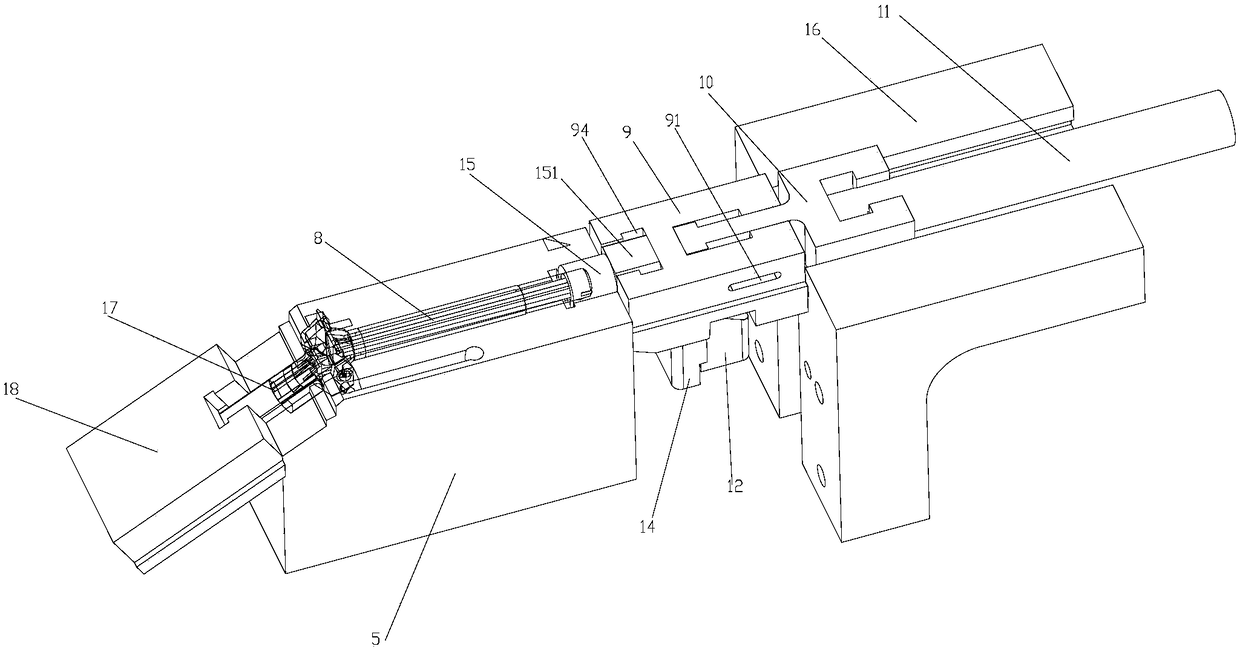

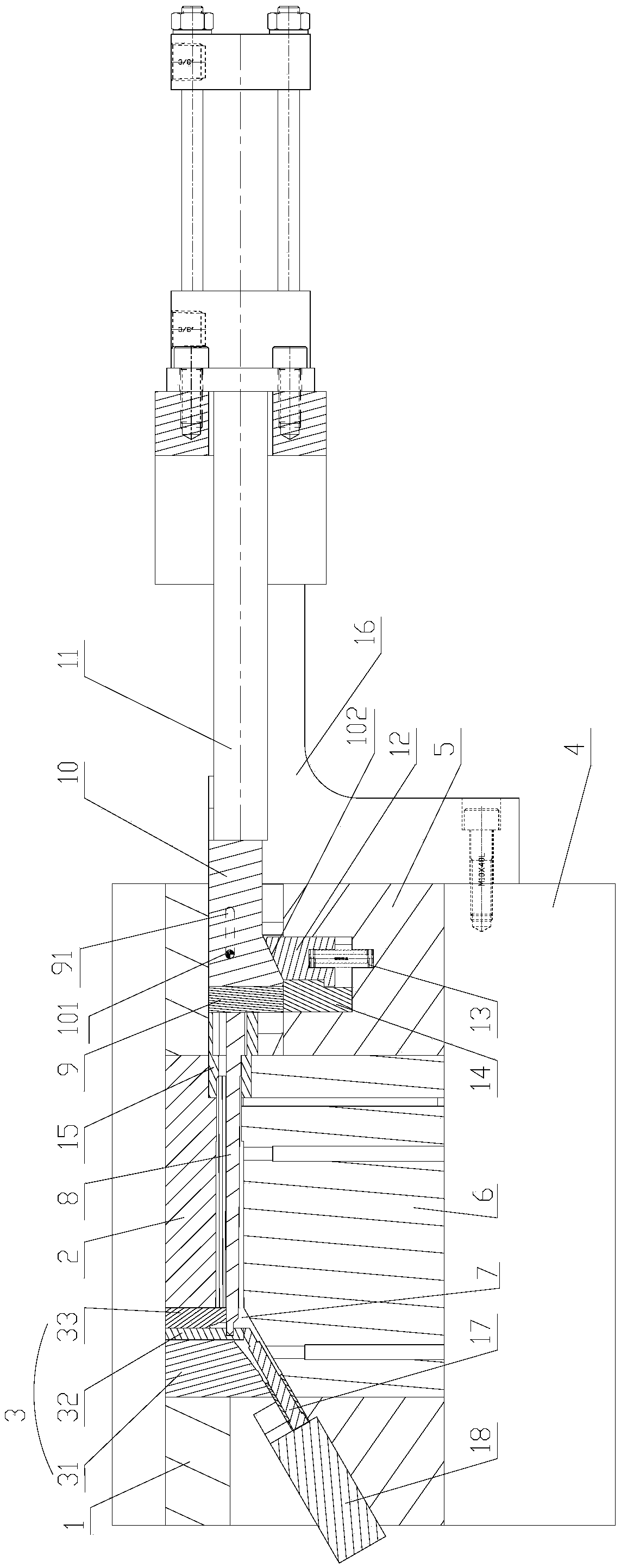

[0020] Examples such as Figures 2 to 6 As shown, a car handle bar forming structure is used for processing such as figure 1 handle bar shown. In order to facilitate the forming of the mounting hole at the end of the handle rod, the handle rod forming structure includes a fixed die set and a moving die set, the fixed die set includes a fixed template 1, a fixed die insert 2 and a Assembling the fixed mold core 3, for the convenience of processing, the fixed mold core 3 includes the fixed mold core A31, the fixed mold core B32 and the fixed mold core C33 arranged side by side.

[0021] The moving mold group includes a supporting plate 4, a moving template 5 and a moving mold insert 6 arranged on the supporting plate 4, and the moving mold insert 6, the fixed mold insert 2 and the fixed mold core 3 are surrounded by a handle bar for injection molding Cavity 7, the handle rod injection molding cavity 7 is provided with a side core 8, the fixed mold core B32 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com