Asbestos paper wrapping device used for cooling after roller surfacing

A technology of asbestos paper and roll, which is applied in the field of asbestos paper wrapping device for cooling after roll surfacing, which can solve the problems of high labor intensity, low work efficiency, and reduced effect, so as to improve the elimination effect, reduce labor intensity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

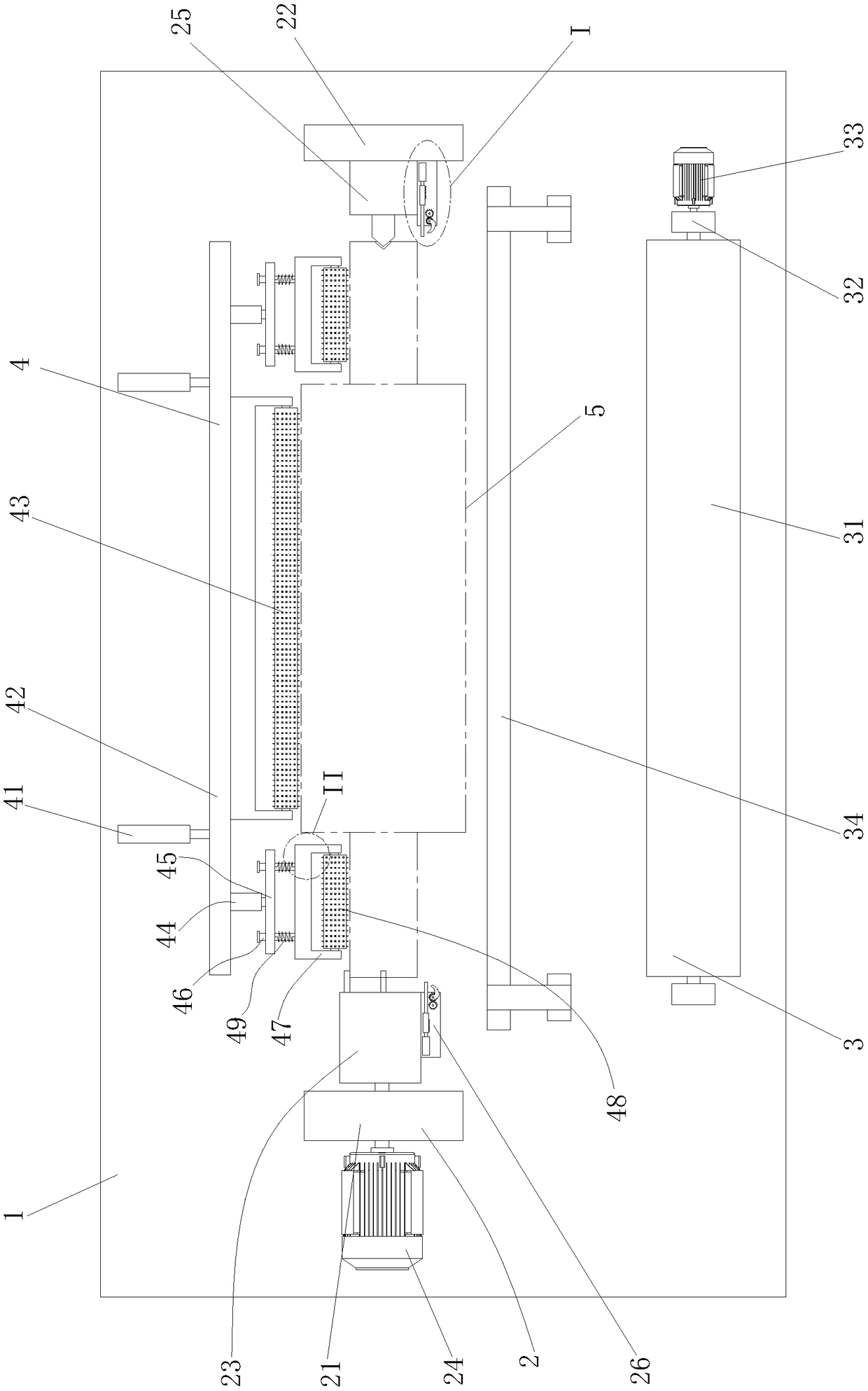

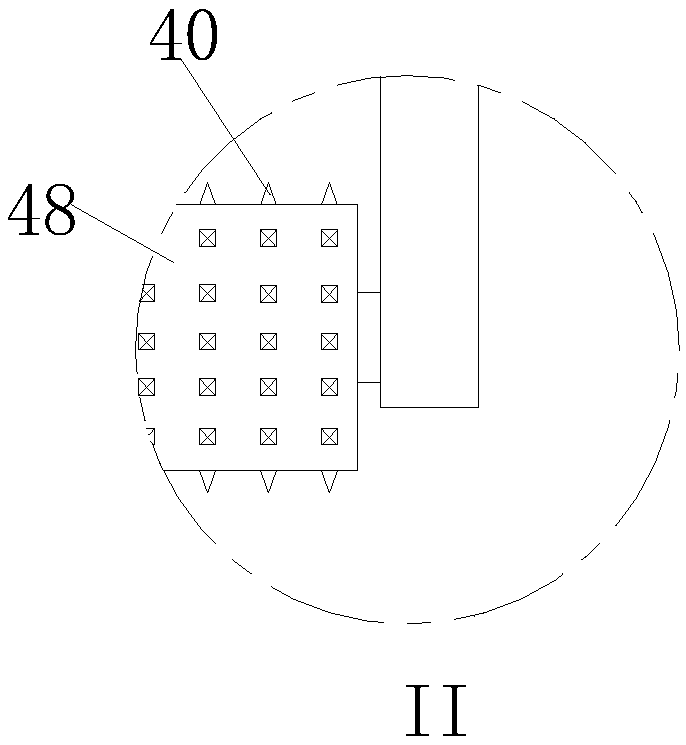

[0020] Such as Figure 1 to Figure 4 As shown, an asbestos paper wrapping device for cooling after roll surfacing includes a bottom plate 1, a rolling mechanism 2 for installing a roll 5 in the middle of the bottom plate 1, and a conveying and cutting mechanism 3 for installing asbestos paper in the front , The rear part is equipped with an adaptive pressing mechanism 4.

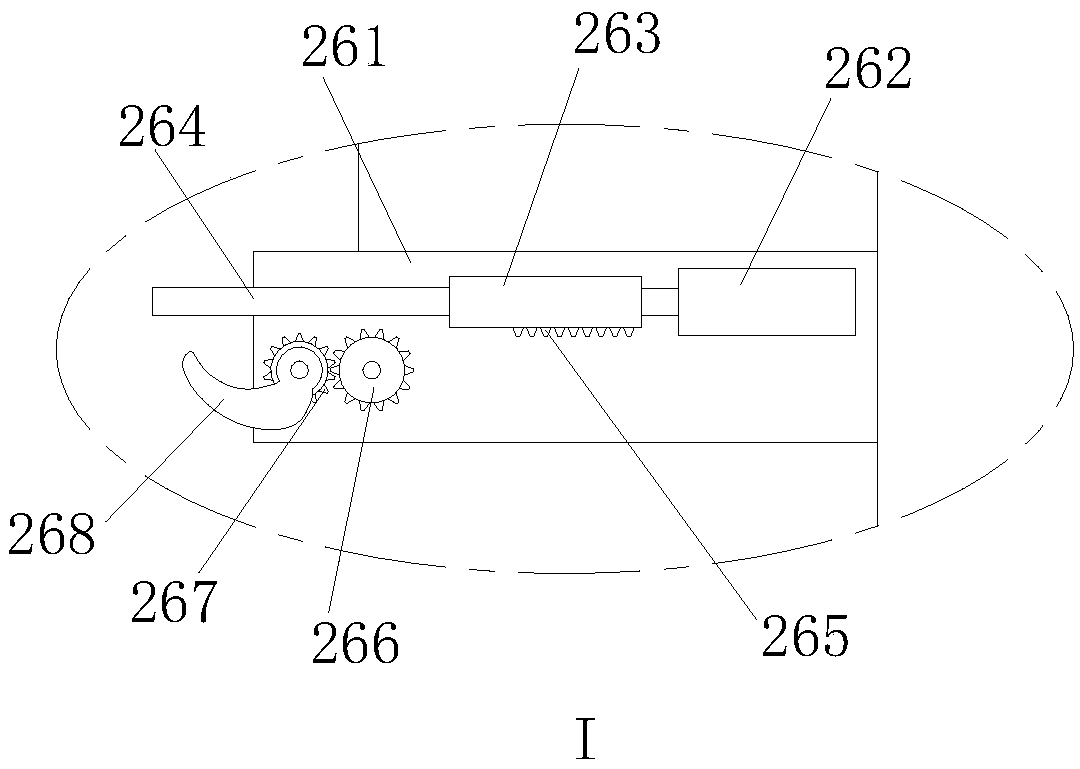

[0021] Described rolling mechanism 2 comprises left vertical board 21, right vertical board 22, the chuck 23 that is installed on the left vertical board 21, the motor 24 that drive shaft links to each other with chuck 23, the thimble cylinder that is installed on the right vertical board 22 25. Both the chuck 23 and the thimble cylinder 25 are provided with a clamping mechanism 26 for fixing the starting end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com